Daniël Nijenhuis: Working smarter (together)

Since the construction industry faces a huge task in the coming years, we will have to work together more and more intensively. In recent years, many productive hours have been lost due to simple administrative tasks that are easy to digitize and automate, so there is still a lot of efficiency to be gained.

In the chain, we see that there is a lot of knowledge and data available that we can use to simplify and automate away processes around ordering, production and invoicing. Many possibilities have been available for years, and with the emergence of AI-like solutions, this will only get faster and easier.

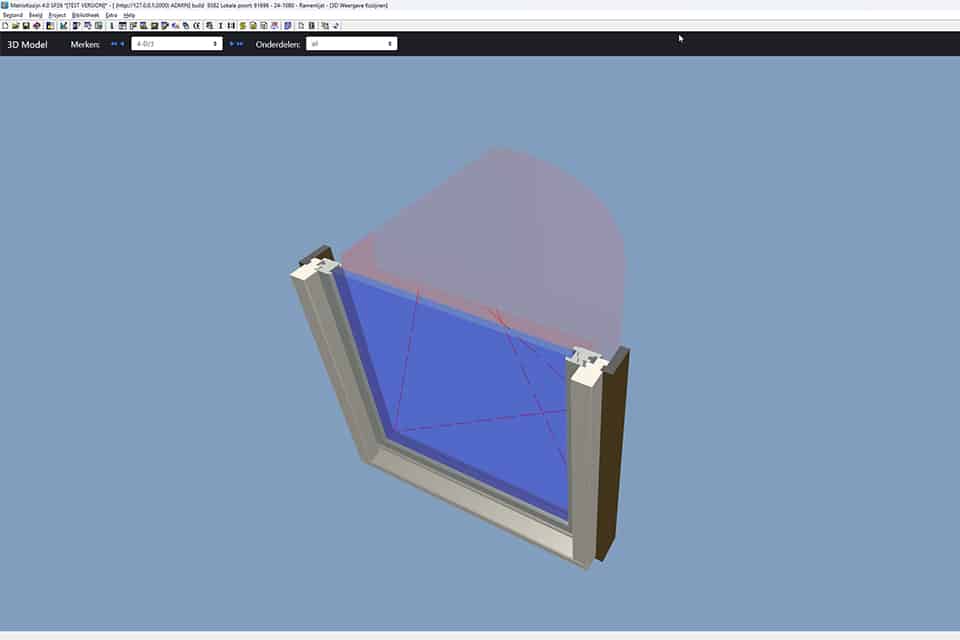

Together, we know perfectly well what schedule we have in a production and we can share this information much more, allowing us to catch peaks and troughs early and fully automate something as simple as inventory management. By linking systems and sharing information both forward, and backward in the chain, we can connect faster to the needs and requirements that arise, without the need for manual activities. Connecting a work preparation package of a window frame manufacturer to the inventory management system of a supplier is a good example of this, as a result of which the availability of the right components at the right time becomes much better and we are not dependent on the human factor in this and can therefore add hours in production and prevent downtime.

With the rise of AI, the predictability of production will only continue to improve into the future, and the need may even be relayed to the manufacturers of all the parts around a window or door, allowing them to proactively shift gears in their own production, preventing inefficiencies throughout the chain.

So how do we do this? Well, by having more confidence in working with the partners in the chain and looking at the cost of the entire production process and not the cost at the item level. After all, human hours and downtime are much more expensive, than those few percent purchasing advantage achievable by changing suppliers.

This does require something of a collaboration, namely openness and transparency and the mutual will to improve the effectiveness of the chain. Sharing a production schedule, with all available data, throughout the production chain, only works if it is based on long-term cooperation, with all parties contributing in cost savings and risk management.

Of course, competition is necessary and desirable to keep each other on their toes, but the basis lies in the desire to fulfill the building contract so that housing becomes feasible and affordable for everyone again. Let's start with the first small step by talking to each other about the opportunities we see together to make the entire process more efficient and get to work on this. This will not happen without mistakes, but we must see these as learning lessons in order to reach the ultimate goal and pay for them. If that will and acceptance is there, one day we will build 100,000 homes in one year!