Main plant in Stuttgart paragon of automation

World player in attachment systems remains committed to a better future

If you want to stay ahead as a company, you must not wait and see what the future brings, but actively anticipate it yourself. This theme ran like a thread through the nineteenth International Roto Trade Press Day, this time with the headquarters near Stuttgart as a backdrop. The assembled international trade press was updated on important topics such as automation of production processes, CO2 reduction and energy savings. With this, the world player in hardware systems for windows, doors and skylights thinks it is ready for the future.

Of the fifteen production plants of the Roto Group worldwide, the main plant in Leinfelden-Echterdingen - close to Stuttgart - is one of the most modern. This also became clear during the tour of the plant. Employees on production lines and forklift drivers are not to be found here. Instead, advanced robots and self-driving vehicles ensure that everything is kept on track. "Mainly because of the relatively high labor costs in the Stuttgart region, we are forced to automate the production process to a great extent," explained plant manager Almir Poric. "After all, highly specialized skilled workers predominantly work here. German craftsmen are highly regarded worldwide anyway."

Local-for-local

Also in the Intralogistik department, it is a coming and going of self-driving vehicles that transport pallets with all kinds of fittings to a pre-programmed destination at the production plant. "All aimed at making the logistics process more flexible, efficient and faster," clarified team leader Stefan Duge of this department. "With this fully automated logistics, Roto is incidentally unique in the industry." During the train tour through the factory halls, the invited trade press fell from one surprise to another. The spectacular finale was the warehouse whose imposing dimensions reminded many of a cathedral. Here too, the fully automatic process means that almost no employees are involved.

"From here, Roto products are primarily transported to European customers," emphasized Petr Jehlicka, head of the customer and market logistics department. "This is because Roto produces local-for-local as much as possible. That means that products needed in Europe are also produced in Europe. The same applies to our other important markets, including America, South America and Asia. In this way, the number of transport movements is kept to a minimum and CO2-emissions reduced."

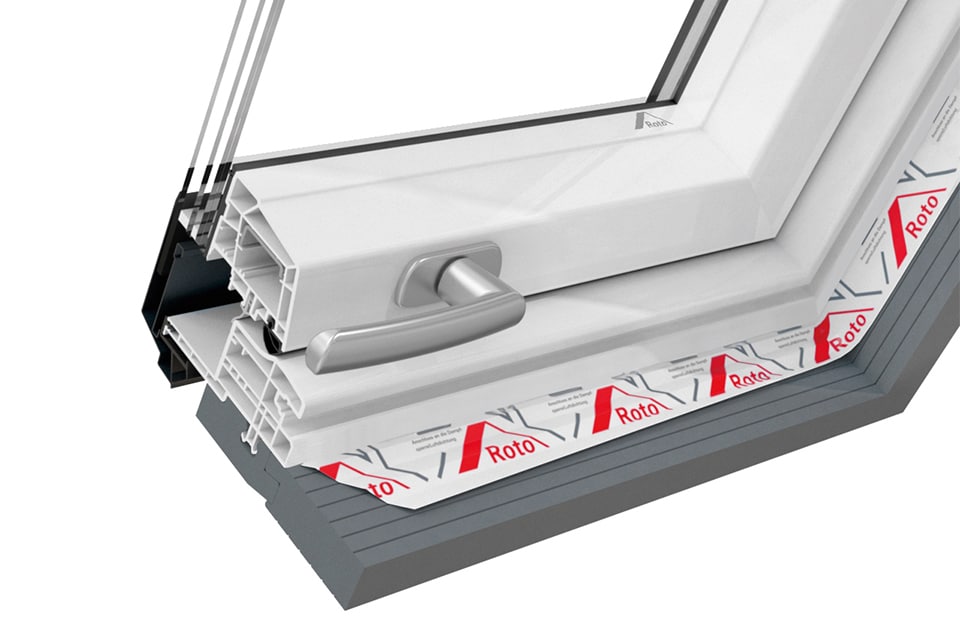

Hollow chamber profile

About CO2-reduction: This topic was also discussed in detail on day two of the International Roto Trade Press Day, during which the international gathering moved to the nearby, stylish Solitude Castle. Dr. Eckhard Keil, Managing Director of Roto Frank Holding AG, pointed out that thanks to the millions of modern windows installed, Roto has in fact been making an active contribution to CO reduction and the fight against climate change for decades. A good example of that sustainability is the hollow chamber profile that Roto has been using in its plastic windows for almost thirty years, as Chief Christoph Hugenberg of the Roto Roof System Technology division explained. "Today, by the way, this profile consists largely of recycled plastic. As a result - compared to the production of new plastic - a CO2-reduction of as much as 88 percent was achieved. Moreover, compared to a profile with a wood core, a hollow chamber profile provides much better stability, insulation and longevity."

Infrared window

When it comes to cost- and energy-efficient solutions, Hugenberg had another innovation in store for those present. Whereas the Designo Heat was already presented as a world first at the previous edition of the Roto Press Day, Roto has further perfected this roof window with integrated infrared window and has now successfully launched it on the market. "This innovation is a real 'gamechanger' when converting and renovating attics," Hugenberg claimed. "Instead of having to laboriously lay heating cables in the attic and invest in heat pumps, this powerful infrared window can take over the heating function. In addition, this skylight reflects as much as 97 percent of the infrared radiation into the room."

Energetic renewal

The latest shoot on the Roto Group tree is called RPS (Roto Frank Professional Service GmbH), a department that deals primarily with maintenance and building renovation. Using two practical cases, Managing Director Dr. Christian Faden explained that significant energy savings can be achieved by renewing hardware and sealing window frames. "The energetic preservation of older windows and doors thus also contributes to the necessary CO2-reduction in the built environment," he emphasized. "For example, thanks also to a modernization of a monumental town house in the German city of Siegen, in which two hundred large wood windows were renewed, a significant CO2-reduction and energy savings realized."

Revenue stagnation

As usual at every Roto Trade Press Day, Dr. Eckhard Keil shed light on the company's results in the past pe-riode. With net sales of 885 million euros in 2023, the overall holding company recorded a slight turnover surplus compared to 2022. In 2024, however, compared to last year so far, sales remain 1 percent behind, he announced with some regret in his voice. According to the managing director, this is mainly due to inflation and the associated reduced consumer confidence in many international markets. For 2025, however, he expressed optimism. "Almost ninety years ago, in 1935, the unshakeable belief in a better future and the usefulness of industrialization led to the founding of Roto by Wilhelm Frank," Keil outlined. "Since then, Roto has succeeded again and again in developing hardware systems that were better than the previous generation each time. And this rock-solid confidence in our contribution to a better future is still present at Roto today."

Perfect match

To summarize the development of Roto's international markets in the past year, CEO Marcus Sander of Roto FTT (Roto Frank Fenster- und Türtechnologie) gave a speech. He also referred to the importance of cooperating with international partners to further expand the customer base, including the US company Ultrafab and DEVENTER Profielen in Breda. Commercial manager Jean-Paul Batenburg of the company from Brabant said earlier about the importance of this cooperation: "Combining the sealing profiles from DEVENTER with Roto hardware creates a perfect combination in terms of operating comfort. In addition, you then have a window that performs exceptionally well in terms of wind and water tightness. Not for nothing have systems in which the combination of Roto hardware and our profiles has been used been awarded the "Perfect Match" designation."