Paperless factory on the rise in window frame industry

'Digitized workshop gives full insight into production process'

Working paperless in a digitized workshop is the pinnacle of production process optimization for frame manufacturers. Matrix Software has all the software solutions to make this a reality. "With MatrixProject MES, it is possible to control your production process completely paperless," says Hans Storms, branch manager for the Frame Industry at Matrix Software.

In the design, calculation and production of window frames, software has become indispensable. At Matrix Software, a specialist in building automation, MatrixProject, for example, occupies a prominent place. "This software integrates relationship management, document management, project management, order management and time recording into one total system. This gives the frame manufacturer complete control over the process, from the arrival of raw materials to delivery to the customer," says Hans Storms.

MatrixProject MES

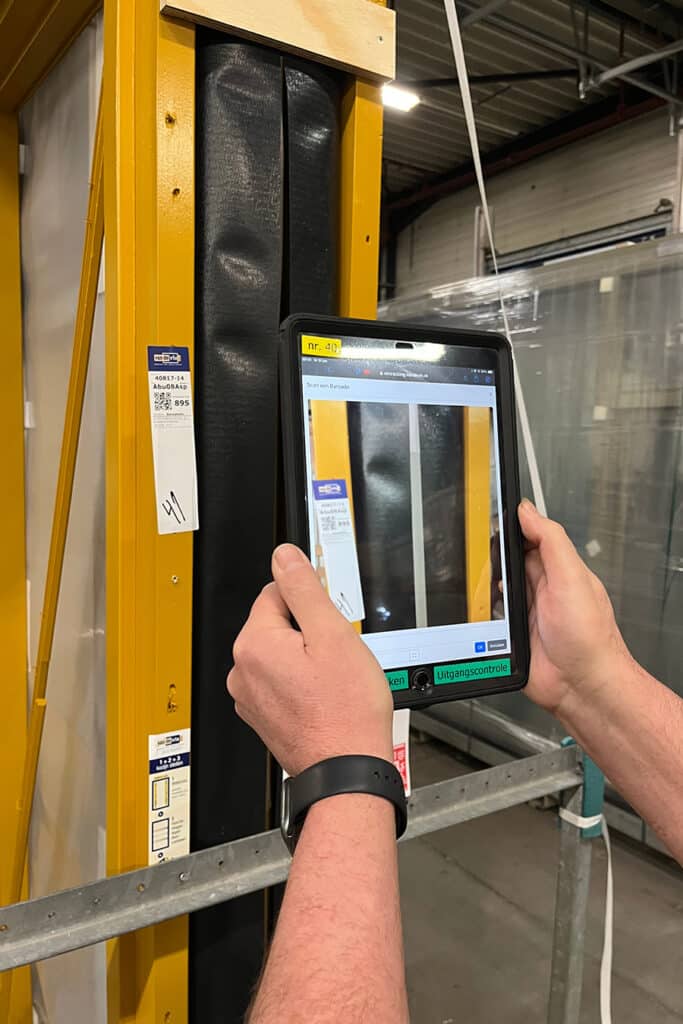

One of the components of MatrixProject is Manufacturing Executed Systems, or MES for short. "The major advantage of this software module is that it eliminates the need to print stacks of paper - even after a change - to provide the plant with the correct information," Storms says. "As a result, MES enables a paperless factory, because employees on the shop floor can view all relevant data, such as production drawings and delivery notes, on a tablet, smartphone or PC. This makes the risk of paper getting lost in the factory and changes not getting through properly a thing of the past."

Product tracking

In addition, MES provides a perfect product tracking system, Storms emphasizes. "Employees on the shop floor scan a barcode of the product, so the office can always see exactly where in the factory the product is located. Also, all hours incurred are registered directly and written away in MatrixProject, creating automatic post-calculation. In fact, with MES, all data is automated at the touch of a button, both for the employees on the shop floor and in the office."

Manage transport trestles

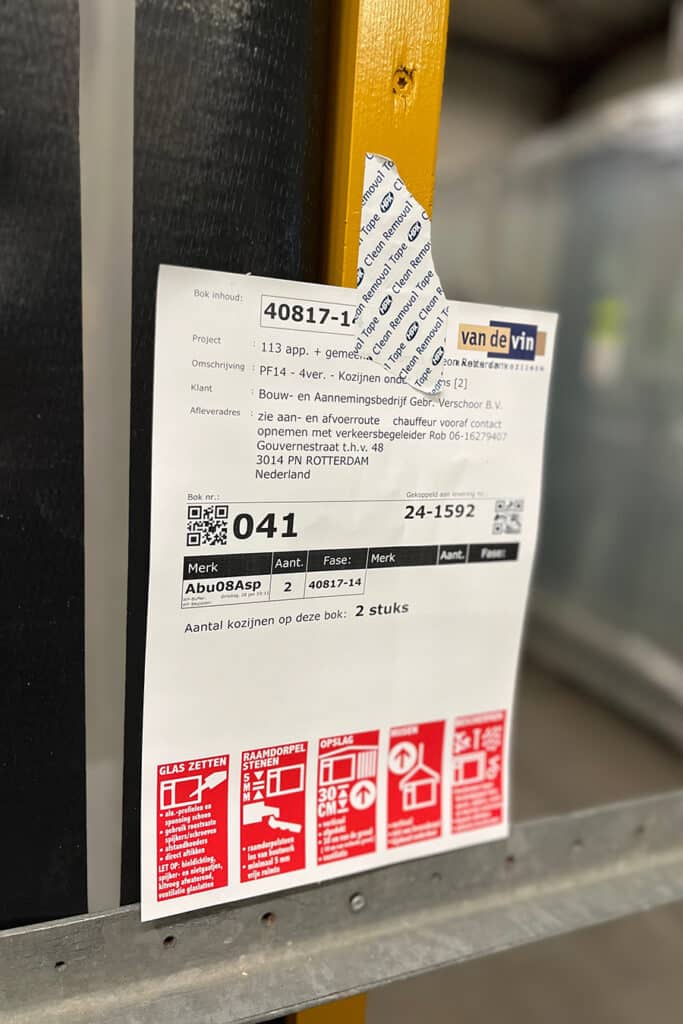

MatrixProject MES is also ideally suited for the entire process of buck registration. "The production process naturally starts with the creation of the delivery in MatrixProject," Storms outlines. "Once the frames are manufactured, they need to end up on the buck for transport to the customer. Well, this entire process of buck loading and shipping is also done using MatrixProject MES. Here, all stickers and delivery notes are printed in the workshop itself, at exactly the right time. This eliminates errors that can arise from lying around delivery lists and pre-printed labels coming from the office. This ensures that buckets are loaded in the most ideal way."

Registration defects

As another advantage of MES, Storms mentions that it allows product defects, such as broken glass, to be recorded easily, after which they are immediately visible in MatrixProject and the work planner can take immediate action. "All in all, MES provides a digitized workshop that gives full insight into the production process," Storms continued. "Within the frame industry, therefore, there is a lot of demand for this MatrixProject software module. For example, we have a customer who normally makes about 350,000 prints for his production process on an annual basis. But thanks to the advent of MES and the digital, paperless factory, many of those printouts have become unnecessary. And less paper means not only a more efficient production process, but also less waste and improved sustainability."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Matrix Software.

Contact opnemen

Contact opnemen