New folding door systems for room dividers and partitions

A functional and aesthetic solution for the separation between working and relaxing at home. But also: maximum flexibility when dividing spaces, a wide passage for people with limited mobility, space saving when opening and closing, less noise pollution and more natural light. It is not for nothing that folding walls are so popular! To create a suitable solution for every situation, Henderson offers three indoor folding door systems for room dividers and partitions. Each with their own unique features and benefits to create flexible living spaces in the home: Huskyfold 30, Roomflex 40 and Roomflex 50.

Henderson has been active on the Dutch market since 1965 as a specialist in various types of sliding and folding door hardware and track systems. The company not only stands for high-quality technical and sustainable solutions, but also for continuous development and innovation based on market requirements and in accordance with the highest product standards.

The wide system range for folding doors is perfectly in line with this and started about a year and a half ago with the introduction of Husky Pro, which guarantees minimal resistance when opening and closing all types of interior sliding doors. Also in combination with accessories such as double softclose or a flush or telescopic mechanism, says René van den Biggelaar, Business Unit Manager Netherlands at Henderson.

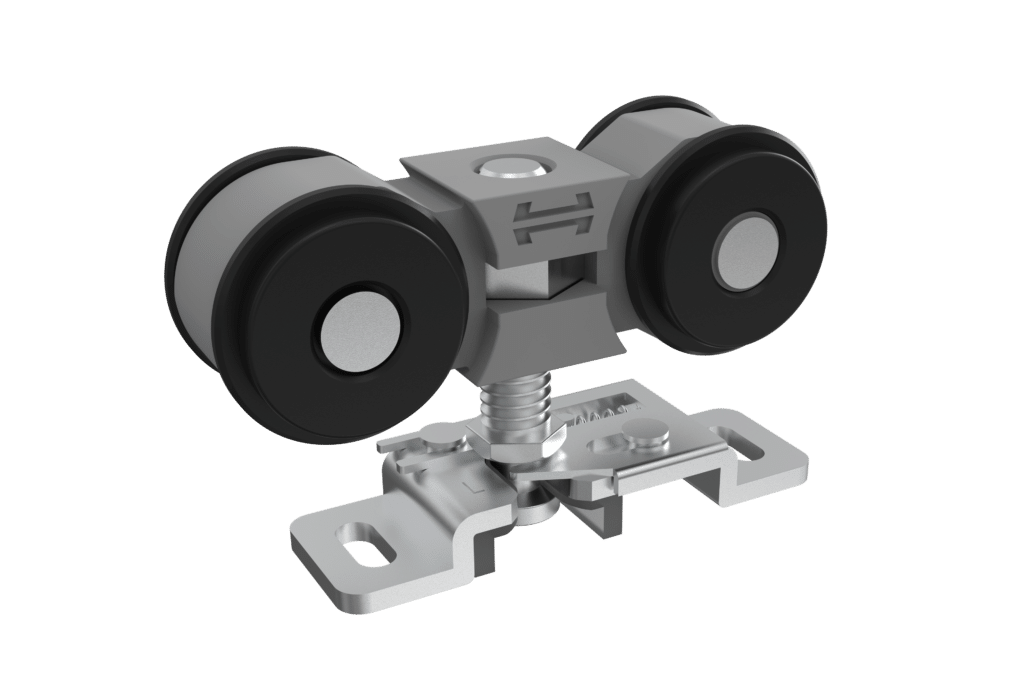

"The specifically shaped wheels and hanging rollers in the runner play an essential role here, ensuring even smoother running while promoting anti-jump. On request, the anodized aluminum rail can be sealed with end caps, and a separate soft-close unit (dual action/open and close side) is also integrated. In addition, users have a choice of manual or electric operation for right-hand sliding applications."

Huskyfold 30 folding door hardware

The Husky Pro system is the basis of several further developments, such as the new Husky Folding folding door hardware for internal folding doors for room dividers, partitions and cabinets. "Our Huskyfold 30 is based on the Husky Pro aluminum rail, casters and hanging rollers and runs considerably smoother and quieter than its steel predecessor," says Van den Biggelaar. "A spring-loaded top hinge and innovative suspension construction allow easy suspension of wooden (closet) doors. Thanks to surface-mounted components, no milling is required."

Husky Folding is suitable for lightweight doors up to 30 kg, he says. "Because there is no bottom guide, users are completely free in their floor choice. Whereas with the old system we could only fold sets of two sashes, with the latest system we can also open and close odd sash numbers. This opens up interesting new application possibilities, for example in combination with a wicket door." Husky Folding folding door hardware is available both in complete sets - for the most common folding door arrangements - and in individual parts.

Roomflex 40 folding door system

Another important member of the folding door family is the Roomflex 40 folding door system. This system is also based on the Husky Pro rail system, except that in Roomflex 40 the rail is behind instead of above the door, Van den Biggelaar explains. "This allows door leaves weighing up to 40 kg to be used without a bottom guide. The hinges and pins of Roomflex 40 are made of stainless steel, giving the system a classy appearance. Moreover, the system is very reasonably priced. Thanks to the addition of an extra offset pendant roller, the Roomflex 40 can now be used for both odd and even numbers of folding doors, making even more configurations possible. Our existing Roomflex 50 system for door leaves up to 50 kg applied completes the family for interior folding doors."

Small and tight covers

A nice addition to the Husky Pro series are the new covers for wall and ceiling mounting, which are smaller and tighter and can be mounted very close to the rail. "This makes them sit tighter on the door and you have almost no see-through space," Van den Biggelaar says. "The latest click and end caps are sleekly square, allowing a very clean look to be created. With this, we are in line with current interior design trends." Instead of aluminum, the latest end caps are made of plastic. This allows them to be attached without fasteners such as screws. Customers have a choice of cover caps in anodized silver or anodized black, in combination with a gray or black end cap.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Henderson Netherlands BV.

Contact opnemen

Contact opnemen