Tilbox in Valkenswaard

As the 2019 Dakar Rally has now started, this is the perfect time to highlight a fantastic project to which Stalufor concepts in construction hardware BV has made a great contribution. Team Tilbox (Dakar 2016/2017 led by director Frank Tilburgs) is part of the company Tilbox in Valkenswaard (formerly Tilburgs Truck Parts). When designing a new company building, TIlbox was looking for a possibility to put the Dakartruck inside in a prominent place. Anyone who has ever seen a Dakartruck up close knows how much space is needed in a facade to allow passage. Because the sliding door wings were extremely large, wide and heavy, added to the fact that there was a desire for a fully automatic door solution, our client Alument BV engaged us for this complex issue.

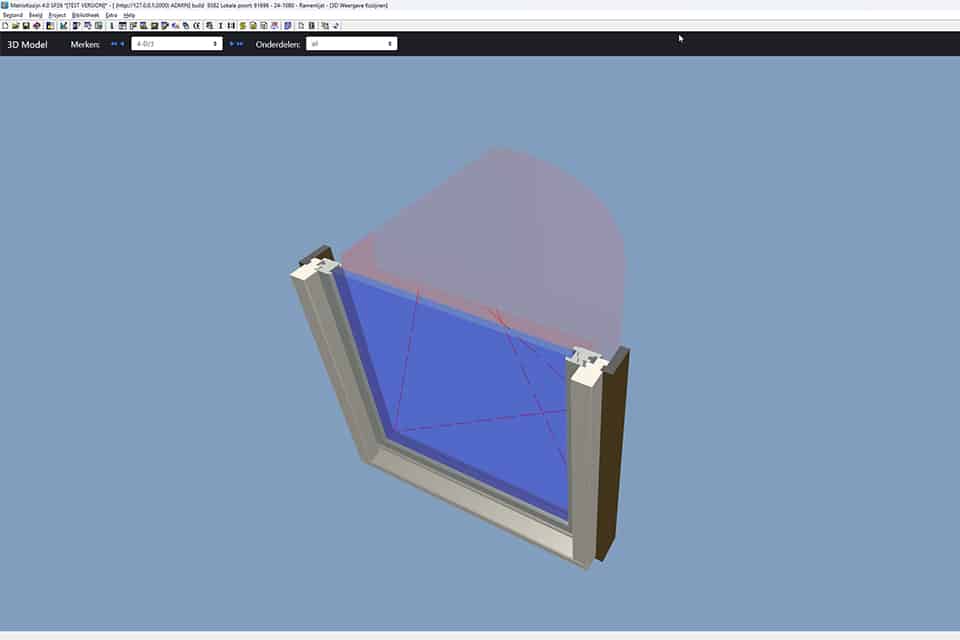

It soon became clear to Stalufor's technical commercial advisors that realizing such an automatic door solution would not be feasible using a single sliding door operator. Due to the width of the daylight opening and the weight of the sashes, two separate dormakaba ES 200 sliding door operators were recommended. Here, automaton 1 determines what automaton 2 should do. The first receives the signals from the user (master) and transmits them via data to second automaton (slave).

Our client Alument, specialist in facade construction, has placed runners under the wings (weighing more than 300 kg each) to guide the automatons. Alument has the production in-house, allowing the most complicated constructions to be realized. Quality and service are also highly valued at Alument.

Tilbox's newly built premises can be called High Tech to say the least. In addition to a large automatic main entrance, the entire building has climate control and the access control is linked to a number of KFV Genius motor locks. In addition to advising on the above solutions, Stalufix Technical Support BV's technical specialists assembled and set up the complex situation. Even after several months, when it appeared that the wings were facing an unexpected but (too) high wind load, Stalufix was on site for a survey and recommended electromechanical adhesive magnets with very high holding power, which were subsequently installed. The adhesive magnets are connected to the emergency power supply and are linked to the dispensers so that the customer does not have to do any additional operation of the dispenser. To complete the sleek design of the facade, the adhesive magnets were painted in color before installation, the end result is impressive!