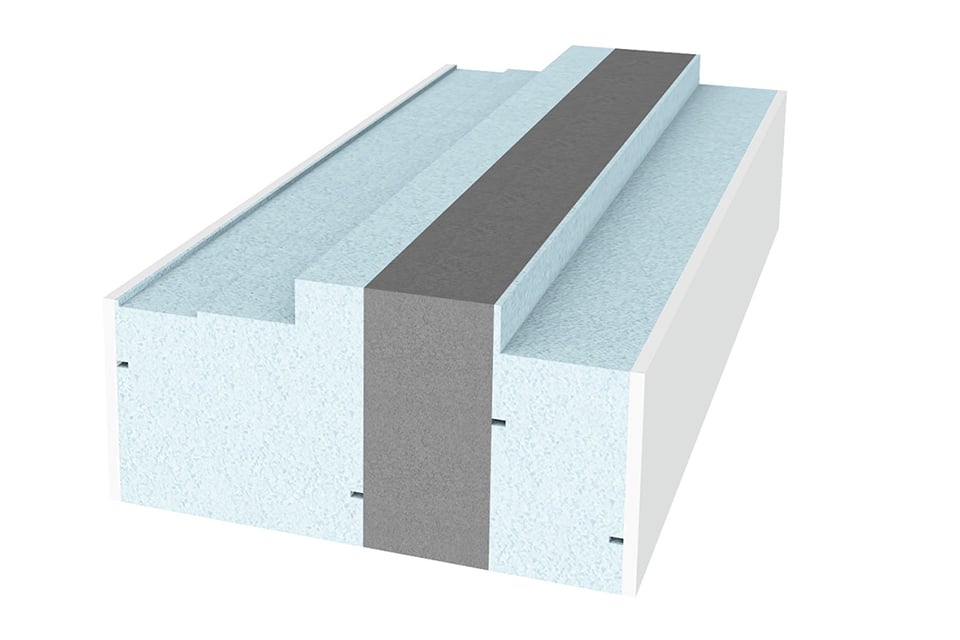

Sandwich element with polystyrene foam core without top layer

Drive for innovation at sandwich element specialist

Stadur Produktions GmbH & Co. KG has specialized for more than 30 years in the production and sale of sandwich elements, such as Frametec and ProfileTec, constructed from a core of StadurFoam and extruded polystyrene foam with a layer of Stadurlon plastic on both sides. With SKS, the specialist then developed a sandwich element with a core made of extruded polystyrene foam, produced and supplied without a top layer. The panel is self-adhesive on one or both sides, allowing the customer to apply almost any decor of his choice.

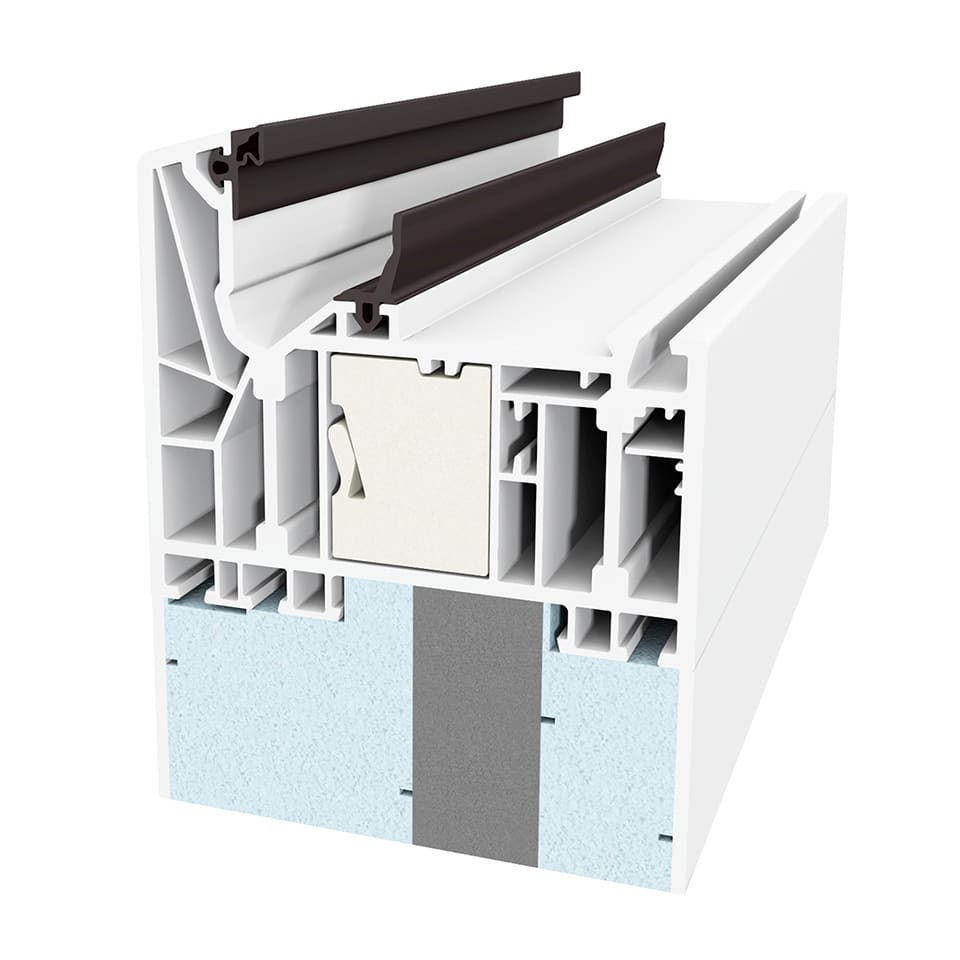

Sandwich elements

In order to continue responding to customers' demanding demands, Stadur must continually expand and optimize its product portfolio. Just think of FrameTec and ProfileTec. These sandwich elements are composed of a core of StadurFoam and extruded polystyrene foam with a layer of Stadurlon plastic on both sides. They are used as frame wideners in the installation of roller shutter boxes and the connection of window sills or in lift-slide systems, high windows and the installation of sills.

“Both products are available in different heights of up to 500 mm and in lengths of up to 7000 mm, enabling jointless frame widening even for large elements. They are characterized by a bending strength of more than 3.1 Mpa and an excellent pull-out value vertically of up to 6310 N and horizontally of up to 2815 N. This ensures a precise and flat connection for each profile. Furthermore, the material absorbs almost no water (< 1.5 %) and is completely rot-free. The panels are also light, which improves handling. Nevertheless, they can handle loads up to more than 1000 kg/lm. Finally, thanks to the easy fastening with screws, without special tools, pre-drilling or doweling, one saves time and money,” says Tyson Ender, sales manager Benelux and deputy general sales manager.

“These sandwich elements were subjected to thermal insulation tests at Schüco's technology center. To ensure maximum security in terms of stability, they were also successfully tested - in an arrangement with the screws and fastening brackets from SFS and the window profiles Living 82 from Schüco - at the ift in Rosenheim according to the ift standard MO-02/1 2015-06 and the ETB standard 1985-06. Other tests, in turn, demonstrated excellent tightness with an air permeability class 4 according to DIN EN 12207 and a driving rain density class A9 according to DIN EN 12208.”

Adhesive DIY sandwich element

SKS is another great example of the drive for innovation. This panel consists of an extruded Polystyrene core without a top layer, but with an adhesive film on one or both sides. Thanks to the very high adhesive strength, one can apply quasi any possible decors to the foam. “This DIY sandwich element is available in thicknesses between 8 and 80 mm and in the formats 3000 x 1000 mm and 3000 x 1500 mm. Other formats are available on request. We have various sizes and thicknesses continuously in stock, so we can deliver them at short notice. SKS is UV-resistant and absorbs almost no water. These panels are also light, which improves handling. The material can be easily machined and cut to size with a cutting blade or metal tool,” Ender explains.

“Thanks to this easy processing and high thermal insulation, this panel offers users many possibilities for the production of window and door panels, facade elements, parapets and partitions, for the construction of cold rooms and container construction, as well as for applications in the medical and automotive sectors, among others.”