Not just thinking sustainable, also doing sustainable

It is said that only sustainable companies have a future. They have certainly understood that message well at Hydro. The global market leader in aluminum solutions is keen to create a more livable society thanks to the development of innovative, sustainable products and solutions.

Cradle-to-Cradle (C2C) or reusing existing products from society as raw material for a new product is a hot topic at Hydro. For example, the WICONA brand launched a unique window system produced with "post-consumed" material: WICLINE 75 MAX.

Hydro is one of the largest producers of primary aluminum and a major European supplier of extruded products, including to customers in the construction industry.

"We are still the same goal-oriented company that was founded in Norway more than a century ago. The emphasis is on innovation and sustainability with the ultimate goal of creating a livable and safe society with a healthy climate and clean environment," says sales director for the Netherlands Joris Verhiest.

"We consciously choose not to use materials that are harmful to the environment and also the CO²-emissions during the production process are kept extremely low. Moreover, our basic aluminum raw material can be recycled endlessly without loss of quality."

Hydro also continues to invest to optimize its production facilities to produce and process the 'post-consumed' material for the new products of the various brands. Post-consumed means that the aluminum used has already reached its end of life as a product before being reintroduced into the chain.

True sustainability

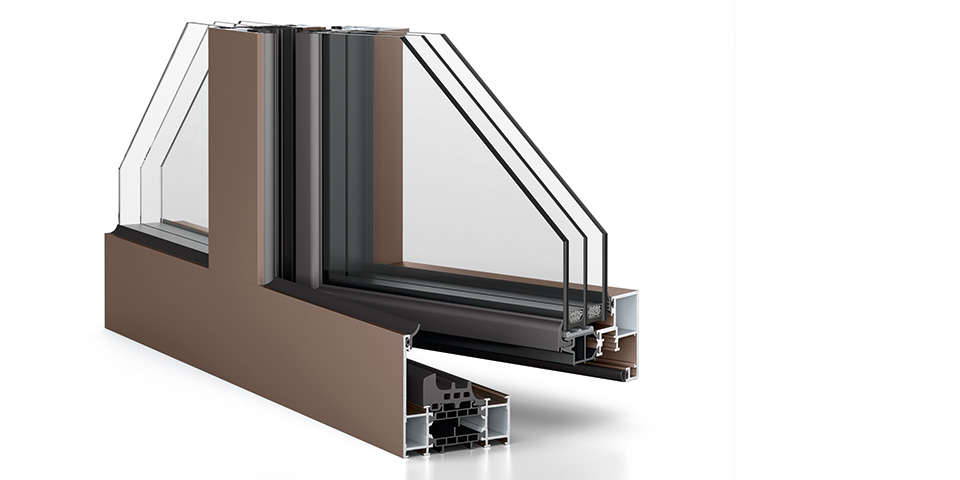

One of these new products is the unique window system WICLINE 75 MAX with a construction depth of 75 mm and an excellent Uw value of up to 0.81 W/(m²K), technically based on the successful WICLINE 75 series. The addition "MAX" stands for the high innovation potential, harmonious design, high transparency and high recycling content.

To produce the latest products, Hydro uses

'post-consumed' material. The scrap metal is sorted, smelted and processed in the company's own production facilities. (Image: Käre Foss)

"Only recycled (post-consumed) aluminum (certified by the 'DNV GL Business Assurance Norway AS') is used for the production process of the window profiles," explains Verhiest.

"In addition to the aluminum in this window system, the thermal bars are also supplied from recycled polyamide. This is unique in the sector and in this way this system has a significantly improved ecological balance. This new solution therefore received the Cradle-to-Cradle (C2C) Silver certificate, immediately complementing and providing an alternative to the well-known building certificates (DGNB, LEED, BREEAM, etc.), where the criteria are product-related."

True innovation

In addition to its durability, its innovative nature in terms of performance and design also makes this product unique. For example, the window system can be equipped with sashes up to a maximum of 1.40 m wide and 2.25 m high, allowing users to benefit from the large transparent surface, which is particularly noticeable in narrow and high windows. Compared to a conventional window series with very good Uf value, for a 0.55 m x 1.8 m window with the same type of glass 56 %, for example, this WICLINE 75 MAX offers more transparent surface.

"Hidden sashes provide a uniform appearance on the outside, so that the fixed and opening parts are indistinguishable. On the inside, too, we opted for a minimalist design with hidden hardware, even with a new, innovative window handle, which is fully integrated into the sash and can also be coated exactly in the color of the profile," Joris Verhiest continues.

"The innovative design concept of this concealed window handle was awarded a 2018 iF Design Award (Product - 'Building Technology' category). and a Red Dot Design Award in the Product Design category."

Ready for a green, sustainable future

The revolutionary WICLINE 75 MAX window system consists of "post-consumed" material. It is characterized inside and out by a minimalist design, where fixed and opening parts are indistinguishable.

Hydro has already taken many actions to be green and sustainable and aims to offer its customers the "greenest" aluminum in the industry. The Extruded Solutions division already uses "post-consumed" material for the production of aluminum building elements, while the customers of the Primary Metal division also use the material for their products and solutions. So Hydro is not only thinking sustainably, but doing it.