Wear-resistant, wind- and waterproof sill for plastic lift-slide door finds its way into profile house

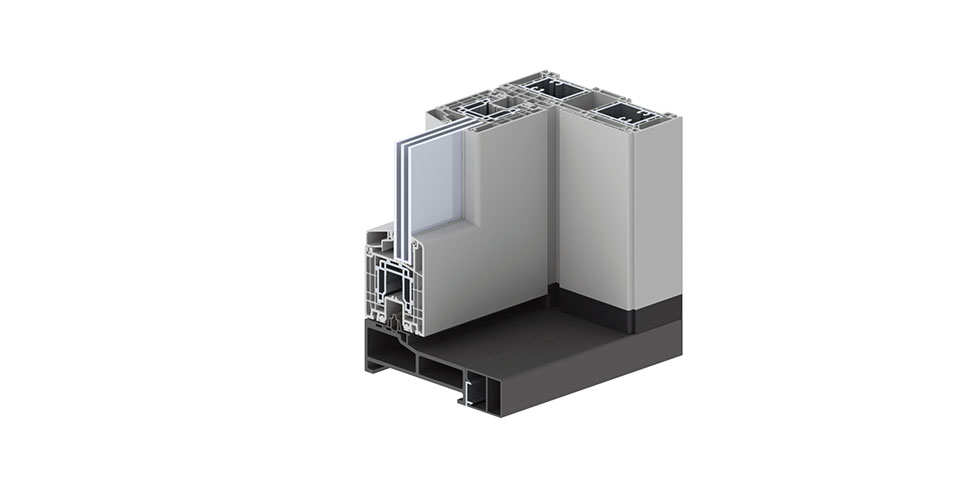

Sometimes the market demands specific products. This was also the case at Venster Techniek, where a request came in from the market to create a variant of the proven EEAL sill for plastic window frames, this time for use with Gealan's plastic Lift&Slide doors. Thomas Keizer of Venster Techniek says: "Especially for Gealan's S9000 series, we have now developed the EEAS sill for plastic frames, completely adapted to Gealan's S9000 profile. The sill is 190 mm wide and fits seamlessly to the frame thanks to special shims."

This makes Gealan the first profile house for which the famous fiberglass-reinforced sill for lift-slide doors is available. "The sill can be ordered as of now. In addition, we are looking into whether we can also realize a similar sill for the other profile houses," Keizer said.

Fiberglass-reinforced and abrasion-resistant, customized for profile houses

EEAS sills meet the requirements of the Building Code and are wear-resistant. The good properties derive partly from the fact that this sill is made from glass-fiber-reinforced base profile with a high-quality coating. As standard, the entire sill is supplied in Stone-Look. Keizer: "This makes the sill extremely wear-resistant and thus retains its aesthetic value. The sills are produced profile house-specifically in house so that the transitions on the window frame styles are not a problem, but connect neatly to the sill."

The EEAS sill is fully aligned with the EEAL sill for Gealan. This provides an aesthetic appearance to the home. Standard sills are available up to a length of 7 meters. Also, the sill for plastic lift-and-slide doors has the same depth as the plastic profile, so frame production is not hindered by a protruding sill. "There are centering pins mounted in the neutral to prevent twisting of the style relative to the neutral. In addition, the door runs very smoothly over the rails because stainless steel was used here."

The EEAL sills for plastic frames that Venster Techniek produces for the various profile houses are custom manufactured, so also for the Gealan S9000 system.

"The advantages are many. These custom sills are light in weight and easy to process by the frame factory because they are delivered fully assembled. In addition, they are available with and without a double seal and with glazing directly on the sill. This allows you to achieve a good seal and eliminates the need to produce an intermediate sill, something that disrupts the production process. Through the pre-assembled glass intake, you can easily integrate the glass frame on the sill. Furthermore, the sill is super-insulating due to the material used in the base profile. Because there are full struts mounted on the sill, the frame style does not need to be "contramed" onto the sill. This ensures that you seal on a plane with the result that you are always watertight. The sill can therefore be fitted under the frame without any protruding parts. We can make sills in one piece up to a length of as much as 7 meters."

A nice addition

Bas van den Eerenbeemt, account manager at Gealan, says about the addition of the EEAS sill: "This is good news for Gealan. We do not supply our own sills and I know that processors who also make Lift&Slide doors with our S9000 system are loyal users of the Venster Techniek sills. The fact that at Gealan lift-slide doors can now also be built with a wear-resistant lower sill is an interesting addition to the pallet of possibilities."