At home in door technology for 90 years

DICTATOR Production, part of the DICTATOR Group since 1988, is celebrating its 90th anniversary this year. Together with the specialist in the noiseless and controlled opening, securing, closing and catching of doors and gates, we look back on a special history, in which the development, control and improvement of products and processes has always been the common thread.

The origin of the name DICTATOR requires a brief foray into history. "A German and Dutchman invented a 'hydraulic shock absorber and shutter for doors' in 1930. In 1932, the patent for it was issued," says Harry Werkman, Commercial Director at DICTATOR Manufacturing. "The special door closer dampens the door as it slams shut and then gently pulls it into the closed position, where it holds it firmly. The inventors called this product the DICTATOR door catcher because it 'dictates' the door in gently catching and securely closing. Since the origins of the current DICTATOR group of companies already had international roots, the inventors chose the international spelling with the 'C' instead of the German 'K'."

Continuous development

The door catcher patented in 1932 is still an important problem solver in 2022. Of course, the product has moved with the times and received several new versions. In addition, production has been automated, allowing the door catchers to be produced even more efficiently, in large numbers and in very high quality, says Technical Director Henry Heidema. "It is not for nothing that the door catchers are crossing the world in large numbers."

The DICTATOR door catcher is still the best-known product in the range. "This door catcher has been catching slamming doors hydraulically controlled and silently for 90 years." Thanks to the door catcher, door handles, padlocks or roller locks can be omitted. "A simple doorknob or elbow hook on the hinge side and a push plate on the day side are sufficient. A big advantage, moreover, is that the door can remain open in any position."

The door catchers are widely used in offices, hotels, apartment buildings, nursing homes and hospitals, says Heidema. "Particularly from the latter group, the demand was growing for a closed and easy-to-clean housing. We responded to this with the DICTATOR type 1600, a closed model in which the cylinder and all fixing screws are invisibly and hygienically concealed. Another further development concerns design model DICTATOR VS 2000, which is highly regarded by architects thanks to its sleek appearance and closed housing."

Over the years, DICTATOR has developed and marketed various types of door checkers, so that nowadays there is a solution for almost every door situation. There are special versions for use on sliding doors (type 1100 and type 1700). Junior has also developed miniature versions of the door catcher for use on small lightweight doors.

Ideal place for an ambitious company

DICTATOR Manufacturing was founded by the Trapman family on June 6, 1932, shortly after the DICTATOR door catcher was patented. The company name then was NV DICTATOR door catcher company. The company was initially located in Amsterdam and later in Bussum. "The production of the DICTATOR door catcher started in a garage and expanded little by little," Werkman said. "In 1965, production was moved to Emmeloord, in the Northeast Polder. This location was reclaimed from the IJsselmeer in the 1940s and is about 5 meters below sea level. An ideal place for an ambitious company!"

Together

DICTATOR Production only joined the DICTATOR Group (also a family business where the human aspect is highly valued) in 1988. Until then, Dutch DICTATOR Production and German DICTATOR Group were competitors.

"Both companies had developed independently, based on the patent of the DICTATOR door catcher. In the mid-1980s, however, it became clear that there were no successors within the Trapman family who wanted to continue the business. And so the German and Dutch 'descendants' came together again."

As a result of the "reunification" and joint efforts, sales of DICTATOR door catchers have increased significantly. This led, for example, to an extensive expansion of production. A spacious hall was added in 1996. Because of the sandy soil on the "seabed," this hall had to be built on concrete pillars more than 9 meters long. In 2003, a new modern machine hall was added to replace the old hall. Thus the optimal conditions were created for an ultramodern machine park as well as fully automated cylinder production. "Thanks to our 'intelligent automation', which includes CAD/CAM control of our CNC machines, we are able to produce a wide variety of products in a short time," says Heidema. "In doing so, customers are assured of consistent quality and short delivery times."

Innovative products

Following the door closers, DICTATOR has developed numerous innovative products, always in response to current needs as well as future developments in the market, says Werkman. As an example, he mentions the ZE Design Line door closers with longer stroke, which look very aesthetically pleasing. "The line consists of four compact versions with a stroke of 8, 12, 16 or even 20 centimeters, which lend themselves perfectly to patio doors, balcony doors and store doors where a longer stroke is desired. But this also applies to situations where the distance from the door to the pavement is considerable. Within the range of chain-mounted door closers, our Adjunct 2500 and Adjunct 2550 throw very high points, and with the Piccolo 2600 mechanical surface-mounted door spring we meet the need to reliably close even lightweight interior doors such as room doors, toilet doors and screen doors."

The DICTATOR production facility in Berlin has developed door opening limiters that are an aesthetically pleasing alternative to the widely known storm chains. The use of a limiter ensures that the door cannot suddenly develop more speed in the event of a gust of wind or wantonness, for example, thus guaranteeing a safe opening. The door is limited to its maximum opening position, which also prevents possible damage to materials and people.

Unparalleled quality

Around the world, attempts are regularly made to copy DICTATOR Production's products. "However, the quality of our products is second to none," Heidema emphasizes. "DICTATOR Production - like the other DICTATOR factories - has managed to bridge the gap between the highest quality, flexibility and cost-effective production. For example, the cylinders of our door catchers are very deliberately made of solid material. We also use (longitudinal) lathes that allow extremely small tolerances. Fixed part of the assembly is a built-in quality control. Only after a successful final inspection are the cylinders engraved with a code, which provides information about the exact type and production batch. This allows every production step of every DICTATOR door catcher to be traced."

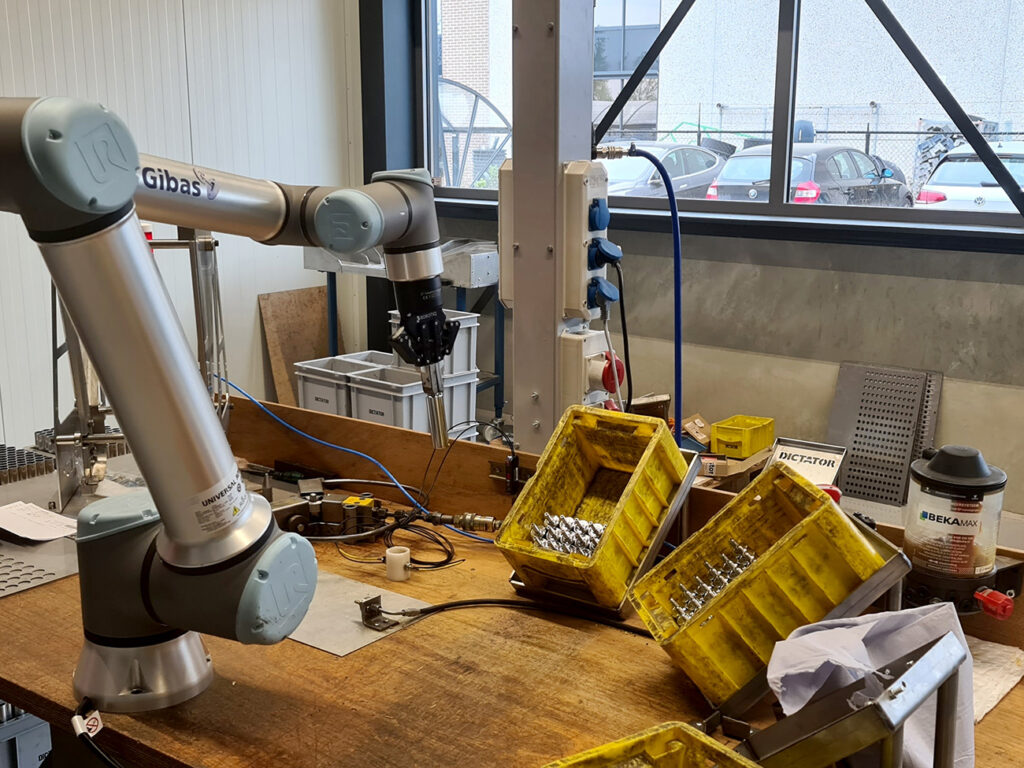

Besides the CNC machines, the advanced production uses Robot and Cobot to make production (cost) efficient and unmanned. In addition, DICTATOR Production has conventional machines for the production of samples and specials, for the development of new products and to ensure the necessary flexibility. All DICTATOR products are continuously subjected to load and durability tests in its own test center. "After all, stability and durability are important quality characteristics of our products."

Sustainable new construction

In order to continue to successfully develop, improve and grow in the years to come, DICTATOR Production has moved into a sustainable and future-proof new building on the industrial area de Munt in Emmeloord in December 2021. The new building was realized according to the standards of GPR Gebouw, which focuses on the themes of energy, environment, health, user quality and future value.

"In addition, logistics processes have been optimized and we comply with the latest sustainability standards," said Heidema. "The new building provides space for a 1,500 m² machine hall, including storage space, where we manufacture our products (energy) efficiently using modern CNC machinery, lathes and robots. Immediately adjacent is a 2,000 m² hall for the assembly and storage of semi-finished products." At the front, the building provides space for approximately 1,000 m² of modern and sleekly designed offices, spread over two floors. Meeting rooms are also set up here, as well as a large room for meetings, courses and product training.

"In the generous reception hall, a showroom for architects, contractors, installers and carpenters will soon be set up. Those who want to can additionally see, feel and experience our products during a tour of our premises."

Numerous DICTATOR products have been integrated into the new construction; from door catchers, Adjunct chain built-in door closers, Hawgood door spring hinges and door hold-openers to spring buffers and HLS catch temperature latches. In addition to these products, DICTATOR Manufacturing has a full supply program of compression and tension gas springs (also in stainless steel type 316), smoke and heat detectors, door retention magnets and anchor plates, door operators for swing and sliding doors, door opening limiters, floor springs for heavy doors and hydraulic dampers for mass braking in a wide variety of applications. The high-quality TJSS door closers (also free-running) from Switzerland complete the delivery program.