World News: Tricoat-Evo. MACO's Premium Surface with Self-Healing Operation

The "MACO-Evo-Effect" is the secret of the new Tricoat-Evo - the new generation and evolution in surface technology for the protection of fittings. Unique in the entire industry.

Fittings are used in windows and doors all over the world and must withstand the widest range of environmental influences and climatic conditions so also in buildings and houses near the coast or regions with high levels of pollution´. MACO has developed a new, unique surface technology that combines exceptional product properties with the "MACO Evo effect" and an ecological production process: Tricoat Evo.

Tricoat-Evo - 3 times stronger than steel

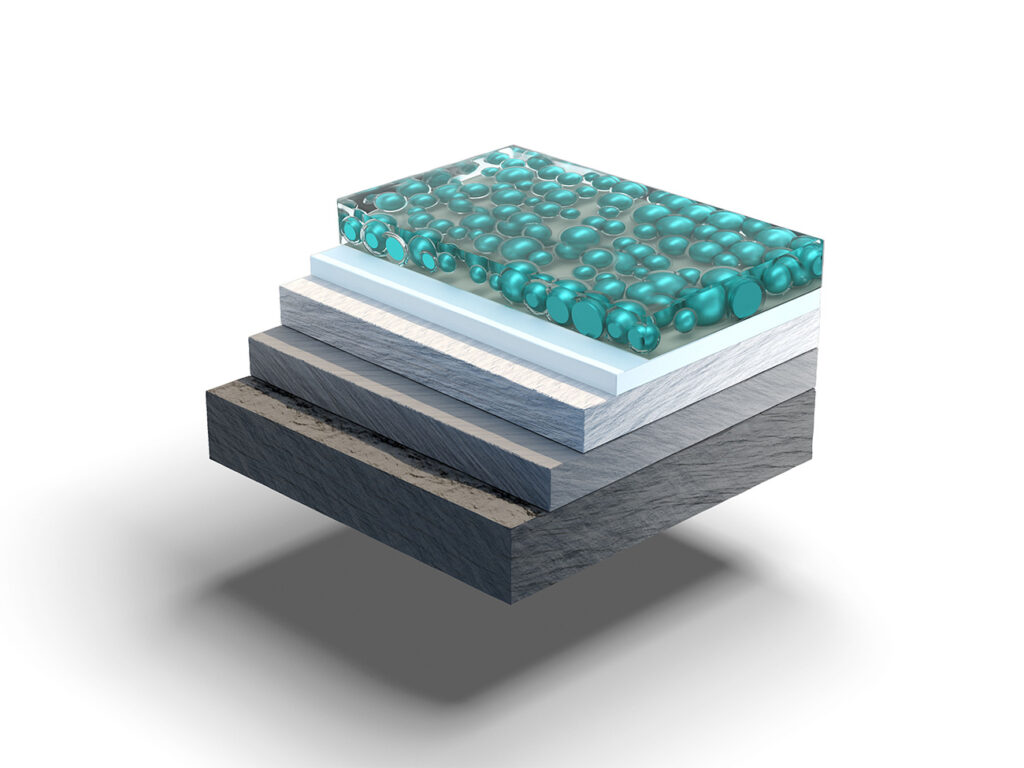

Tricoat-Evo is a premium surface treatment that is a real powerhouse despite its elegant appearance. Four layers, including a duplex layer with 500 to 600 HV according to Vickers, provide excellent protection at friction points. As a result, Tricoat-Evo is three times stronger than steel and has extremely high wear resistance. The multilayer system also prevents rusting through and protects especially fittings in harsh areas, e.g. near the coast, in areas contaminated with pollutants or in acidic forests. MACO confirms this with a 15-year surface warranty.

Thanks to the low layer thickness and the new self-lubricating effect, the hardware runs much smoother than before. The high-quality appearance of stainless steel brings new design possibilities for manufacturers.

The MACO-Evo-Effect

Human skin has a remarkable property: it recognizes and heals minor injuries by itself. MACO has transferred this intelligence to the protective surface layer of its products: thanks to a tribological sealing with nanocapsules. In this process, nanocapsules act as reservoirs for lubricants and corrosion-inhibiting protective substances. If the surface layer is damaged, these substances escape and the scratches are refilled. "This protection is unique in the industry and available exclusively from MACO," says Michael Weigand, Managing Director Sales & Marketing.

Respecting the environment and promoting sustainability

MACO supplies the, in-house produced, surface coating for the entire MACO product range. The innovative surface treatment meets not only product quality, but also the latest legal requirements for environmental protection and sustainability: the process is characterized by low baking temperatures and thus lower energy requirements. The environmentally friendly wastewater treatment, where 97 percent of the wastewater produced can be fed back into the production process, as well as the reduction by around 50 percent of the thin sludge produced and to be disposed of, are visible proof of the requirement to develop the most ecological possible surface technology.