Schans II Rotterdam Delfshaven. Renewal in wood

This year a new residential building with 38 apartments was erected at De Schans and 2nd Schansstraat in Rotterdam Delfshaven. Architectenbureau Groosman designed the new building after the 1911 residential block that stood on this site. Most striking: the rhythm of the FSC sapeli mahogany window frames. They are glazed, painted and finished right off the truck and assembled on site.

On the Schans in Rotterdam Delfshaven, two distinctive residential buildings have stood again since the summer of this year. The small 1911 porch houses of Schans I were renovated by Havensteder in 2018 and merged into 118 spacious rental apartments. Schans II, by the same client, proved structurally too poor to repeat this operation. Havensteder opted for rebuilding based on a design by fellow city architect Groosman. The starting point was that both buildings should fit in line with each other in historic Delfshaven.

38 social housing units

Schans II, built by construction company De Langen & Van den Berg of Bergambacht, consists of a total of 38 new social housing units. These include six two-room houses, seven three-room houses, seven four-room houses and eighteen studios. Groosman carefully translated the details of the old 1911 residential building on this site into the present. That means building on the early twentieth-century architecture with large roof overhangs and clear hoods, decorative elements in the brickwork and bluestone doorsteps. Groosman thus wanted to preserve the old, historic character of this site next to the hull of malt mill ‘Het Vertrouwen’ from 1853. However, without making concessions to the living quality and (insulation) requirements of our time.

269 exterior frames

Most eye-catching of Schans II is continuation of the rhythmic facade so characteristic of town houses from the beginning of the last century. However, the traditional sash windows from that era have all been replaced by modern turn-tilt windows, equipped with HR++. Manufacturer Ebbers Kozijnen from Etten supplied a total of 269 exterior window frames, including bay windows with side sashes, and 23 interior window frames. The frames, tilt and turn windows and doors of the outer wall are made of FSC Sapeli Mahogany (durability class 2). This type of wood is easy to work with and its high hardness makes it resistant to mechanical damage. This hardwood species has a smooth grain and no pinholes, making it optimally smooth to finish.

Short construction time

Director Maarten Ebbers of Ebbers Kozijnen: “Because we position ourselves as co-makers in the field of facade carpentry, we have a long-term cooperation with De Langen & Van den Berg. For example, shortly before completion we have a so-called 5-for-12 refurbishment service. This involves us coming by to check all windows and doors and to provide the client/user with the greatest possible comfort.”

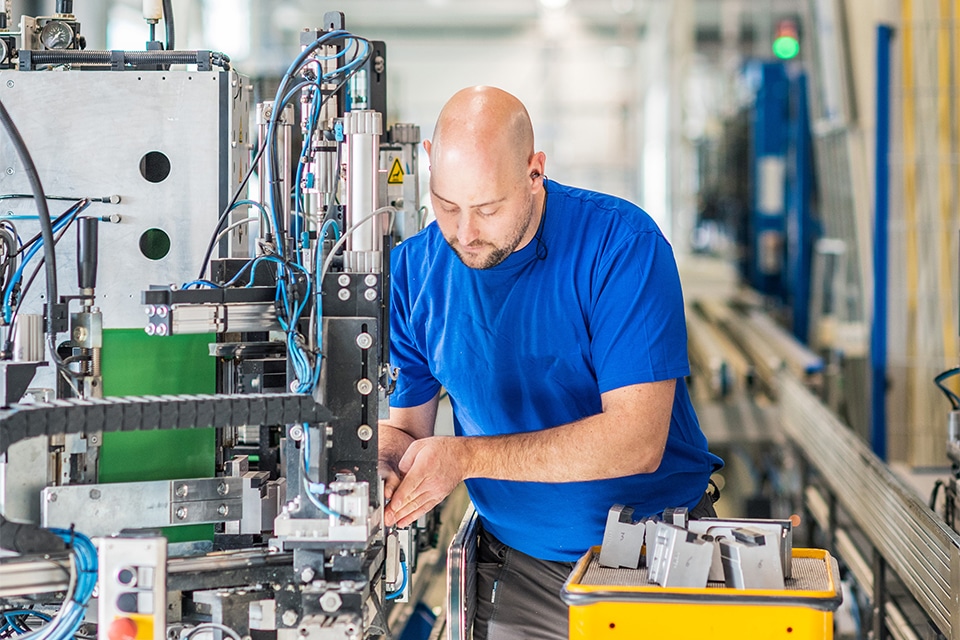

New construction of Schans II began in December 2023, with the first residents able to pick up their keys at the end of May 2025. This relatively short construction time was partly due to the degree of prefabrication used to complete the concrete shell. This applies to the use of hsb cavity walls, but certainly also to the wooden windows and frames. Ebbers: “The window frames were delivered from the factory painted and glazed. The characteristic bay windows with side cheeks were brought to Rotterdam Delfshaven and assembled completely finished, including hoisting equipment and a hardwood connecting post.”

Contractor and frame manufacturer jointly developed a coupling plan for this purpose. Ebbers: “By working this way, you can save a lot of construction time. Moreover, you serve the quality of the wooden façade element. After all, there is no need for painting and glazing during construction and you are not dependent on weather conditions. The facade is also quickly wind and watertight this way.” Some of the wooden window frames were delivered by Ebbers to timber frame builder B&O Group, which installed them in the cavity walls at the factory. That method also served the construction speed.

Maarten Ebbers calls Schans II fairly standard. “This is what we do.” Client Havensteder, architect Groosman and builder De Langen & Van den Berg, but certainly also the residents are reaping the benefits.