Recyclable window frame profile surpasses the properties of wood

Sustainable and reliable for renovation and new construction

To guarantee reliable operation, excellent stability, and a long service life for frames, windows, and doors, all factors must be just right. From design to production, installation, and finishing, and from windows to doors, frames, subframes, seals, glass, and fittings. RecyStel supports this with sustainable, insulating, and 100% recyclable subframe profiles that can be processed quickly and easily. Both in renovation and new construction projects and in combination with plastic, wooden, and aluminum frames. RecyStel also guarantees high quality, reliability, and continuous product development, based on market demands and opportunities.

“The recyclable RecyStel window frame profiles have been very popular for several years among window frame installation companies, carpentry companies, and small(er) contractors who order the products via the webshop,” says Ivo Würzner, managing director of RecyStel. “These are often individual lengths or small(er) quantities that can be delivered within three days and are mainly used in renovation projects. It's a strategy that works well and is also experiencing healthy growth, but there is much more potential with RecyStel frame profiles. For example, our frame profiles are also ideal for new construction projects.”

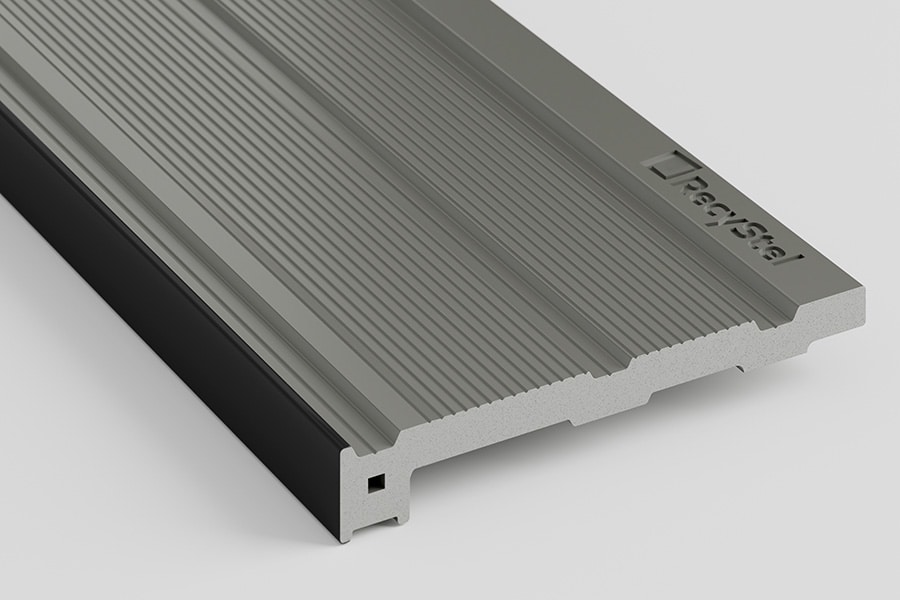

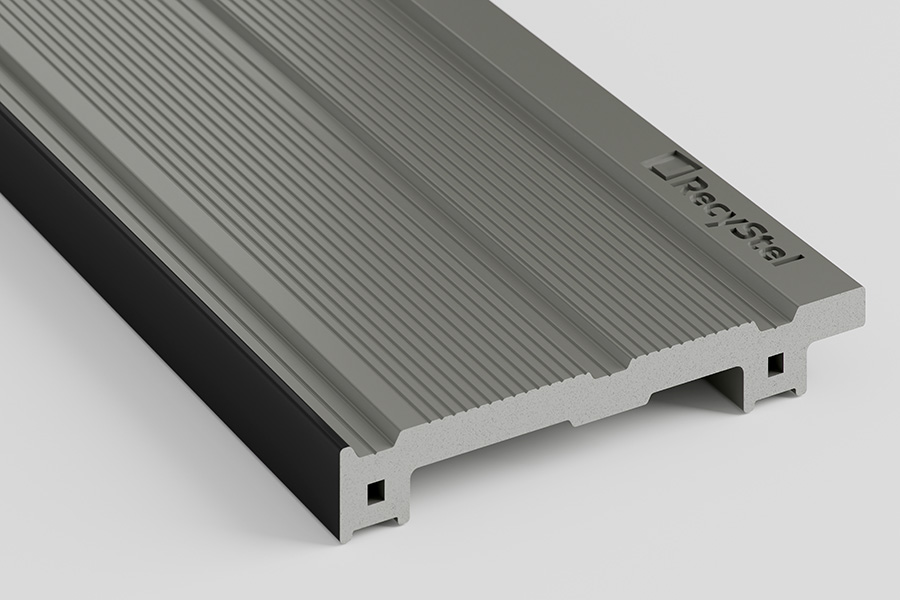

The standard RecyStel frame profiles: R-2005, R-2008-1, and R-2008-2.

Also for new construction

Driven by sustainability, Würzner sees the demand for sustainable, insulating, and 100% recyclable window frame profiles continuing to grow. This is also the case in new construction projects, which are increasingly being built in accordance with BREEAM and Paris Proof guidelines. “In addition to the practical advantages of plastic window frame profiles, such as ease of processing, the circular benefits play a decisive role here,” he says. “The use of 100% recyclable window frame profiles yields valuable points.” Below, he explains the most important advantages:

Manufactured from recycled PVC

“The RecyStel frame profiles consist almost entirely of recycled materials, most of which come from old, dismantled frames, offcuts, and sawing waste,” says Würzner. “Our ‘donor material’ is high-quality PVC, which is completely free of plasticizers. During the extrusion process, a special gas is added to the frame profiles, causing them to foam. The result is ‘recycled foamed PVC’ with high rigidity and a high thermal insulation value of 0.38 W/m2K, which is up to 40% higher than standard plastic! This makes our profiles many times more durable than wood. Cold bridges are not an issue. What's more, the material can be recycled up to 10 times without compromising on quality.”

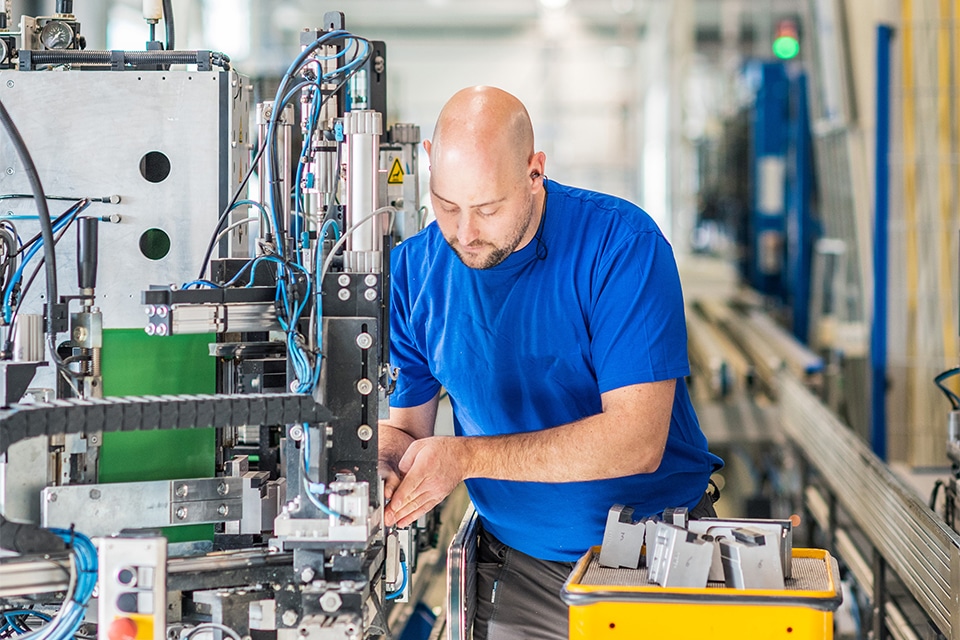

Trusted processing

Because the frame profiles are foamed, they have the same processing properties as wood, explains Würzner. “Processors can easily saw, mill, drill, screw, and staple the frame profiles without the risk of cracking.” However, the biggest advantage of plastic is that its quality remains stable. “Even after a long time and in all weather conditions. The material does not warp or twist. Protective and moisture-resistant DPC films are therefore not necessary, nor is priming the frame profiles. This allows us to respond fully to the current conditions in the construction industry, where lead times are under considerable pressure.”

Easy installation in combination with RecyClick anchors

To keep construction lead times as short as possible, window frame elements are increasingly being delivered to projects fully glazed. RecyStel is responding to this trend with its RecyClick anchors. These stainless steel spring systems can be easily screwed onto the front of the window frame, explains Würzner. “The frames can then be easily clicked into the frame from the outside.” A major advantage of the RecyClick anchors is that there is no longer any need to drill into the frame, which means that the air chambers remain intact. “Because the anchors can be mounted closer to the corners, a high degree of rigidity and stability is also guaranteed.”

Burglar-proof and flame-retardant

RecyStel frame profiles fully comply with fire safety requirements for plastic facade elements and are flame retardant. “The VKG quality mark proves that rigidity, load-bearing capacity, and installation method are excellent,” says Würzner. “What's more, the rigidity contributes to a burglar-proof home.”

Long service life and maintenance-free

Plastic window frame profiles are also an excellent choice when it comes to aspects such as lifespan and maintenance. “Plastic cannot rot or mold and does not absorb moisture, giving it a much longer lifespan than wood. Plastic also does not need to be painted, which significantly reduces the total cost of ownership.”

Less residual waste

RecyStel frame profiles are extruded in standard lengths of 6 meters. “This length is not only based on the crate dimensions and trucks used by our processors, but also results in significantly less residual waste,” says Würzner.

New width sizes

RecyStel frame profiles are currently available in widths of 135 and 204 mm. “Because we have seen that wooden frame profiles are often 90 mm wide, we will also be introducing frame profiles with widths of 90 and 100 mm at the beginning of 2026. This will mean that our processors will no longer need to cut the frame profiles lengthwise.”

Expansion into the large business market

“We are currently investigating opportunities to offer our RecyStel frame profiles to the large business market as well. After all, the above-mentioned advantages are also very interesting for this market,” says Würzner. “However, this target group does require a different strategy, approach, and logistical approach. Among other things, because larger quantities are involved. In the coming months, we would like to work with the market to further develop this.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Select Windows.

Contact opnemen

Contact opnemen