Dutch manufacturer of aluminum window frames and curtain walls invests in fully automated production line from SOENEN

Fast and unmanned production increase efficiency and output

Manufacturing companies that want to remain competitive must constantly question themselves. Central is a drive for innovation but also the continuous evaluation of machinery. When they decided at Van Hoesel Aluminium Kozijnen in Goirle about a year ago to replace their outdated throughput machine, they happened to come into contact with Soenen Hendrik. Soon they will be processing the different profiles for the production of window frames and curtain walls on an automated production line of the specialist from Izegem (Belgium), the fastest of its kind. From now on, they can process even more different profiles completely on the same machine and the lead time is shorter. Moreover, unmanned production can be used, significantly increasing both efficiency and output.

Van Hoesel Aluminium Frames is over 50 years specializing in the design, manufacture and installation of aluminum frames and curtain walls. For this they can count on a team of enthusiastic staff and a highly automated, up-to-date machinery.

"We were one of the first firms in the Netherlands with a throughput machine. Looking at the developments and technical progress over the past 15 years, we decided about a year ago to look for a new machine that would allow us to expand our capabilities even further and increase capacity," says operations director Ruud Baelemans.

"We first made an overview of what the market had to offer. Soenen Hendrik's solutions were not among them, because we assumed they could only be used for plastic profiles. When sales representative Pepijn Carlier slid a catalog under the door in the middle of corona time, the ball got rolling. A positive exploratory conversation followed, where we saw an extensive questionnaire answered. Visiting the factory, we were impressed by the quality and performance of their automated, high-tech production lines for machining profiles."

Unmanned production results in higher efficiency

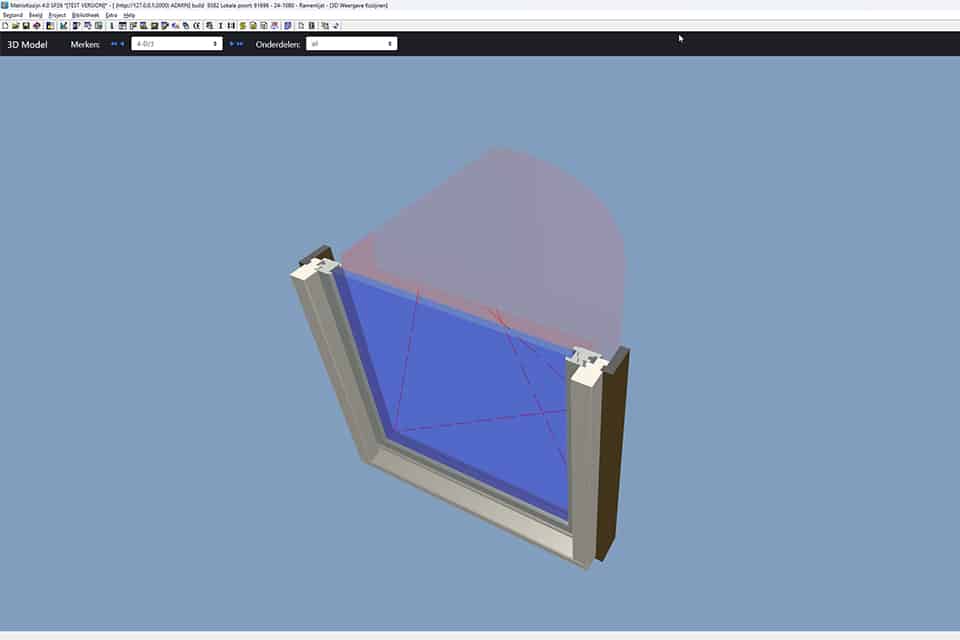

Soenen Hendrik took control of the project right away. R&D, sales, production, software development and integration, assembly, installation, after-sales service,..., and even transport - they do everything in-house. Based on the customer's needs, they developed a production line, which can process all the necessary aluminum profiles. The machine recognizes the profiles placed on the input table by the operator and performs the job perfectly: milling and drilling, sawing and counter-profiling and finally fully automatic sorting on the output table.

"The knowledge is in the machines, which are controlled directly from the software. Control tools, including cameras, prevent any error before and during the machining of the profiles, and there is also self-optimization and automatic tool breakage detection. The machining of the tool, which needs to be replaced, is automatically taken over by other available tools, thus avoiding any machine downtime," explains Pepijn Carlier.

"Since these Smart Machines operate unmanned, operators can be engaged elsewhere in the production process. Capacity is expanded, lead time is reduced and output is increased, significantly increasing efficiency and profitability on the shop floor."

Ready for the future

At Van Hoesel Aluminium Frames can now from the HiCAD and Logikal software packages all possible profiles on one machine be processed. In addition, they can perform more operations, such as counter-profiling, automatically.

"We are very satisfied that Soenen Hendrik came our way. They responded flexibly to our needs and developed a suitable customized solution," Baelemans concludes.

"Moreover, the MR glasses allowed us to see in advance what the production line would look like and how it would be integrated into our production hall. Also during the machine reception in their production hall, it became clear once again how experienced and dedicated the team of Soenen Hendrik is. With this automated production line, we are already ready for the challenges of today and tomorrow."