Greater efficiency through automation

At the new production site of KUFA Raamsystemen in IJmuiden are the new machines supplied by TRYMA. Sales manager Dennis Koning of TRYMA is satisfied: "KUFA has invested well in the logistics of window frame production with the machines from ROTOX and AFS FEDERHENN. With this, the production process is now a lot more efficient."

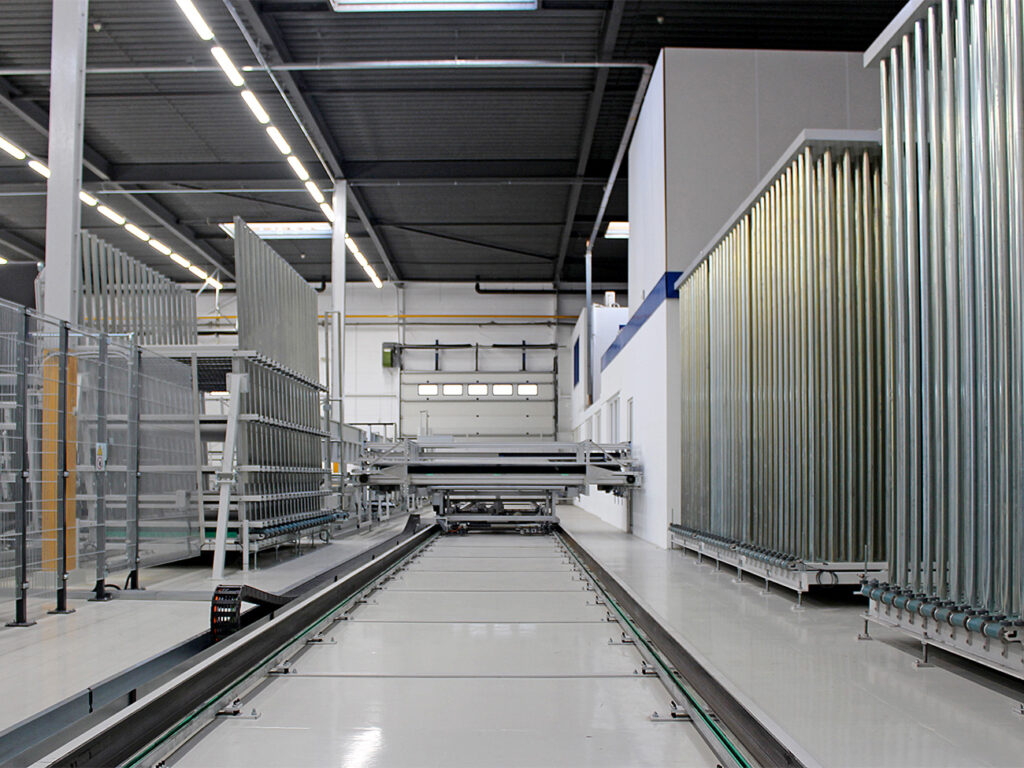

KUFA's new plant was completed in the fall of 2021. Dennis Koning and account manager Bas Claassen look at the final result. TRYMA installed a fully automatic frame and sash buffer, as well as a hardware table, which is equipped with a hardware screw robot. Bas explains that many frame factories underestimate the cost of manual work. "These are big loss items. A company can't really afford that in this day and age."

Dennis adds: "Just study logistics. A lot of time is lost in packing, putting away, sorting and transporting; there is almost always room for improvement. The time this takes is by definition a loss and could be better spent making the frames."

Dennis is clear about the benefits of the new system for KUFA. "The production process now has a higher output with fewer FTEs. That is not an unnecessary luxury in an overstrained labor market where personnel is hard to find. In addition, I am convinced that sick leave will also decrease because the work is less physically demanding and ergonomically improved for the employees."

The software for controlling the complete automatic buffer system was developed in cooperation with Matrix. TRYMA supplied the machines and designed the process, Matrix programmed the process into the software. "For our customers we create added value in this way because we know how a production process should be designed. The result is economic returns with greater efficiency," says Dennis. "With our experience and through research at various companies, we know where the biggest gains can be made."

TRYMA specializes in production lines for windows and doors. "It's a complex product and process," Bas believes. "Just saw open a window frame, there are many more parts and functions in it than you would think at first glance. Moreover, window frames have become considerably heavier in recent years. This is a problem, especially if you reason this out from the employee's point of view, who is also aging. At some point, a physical limit is reached."

Loek Gosewehr, working at this production site of KUFA Window Systems, confirms that the new situation is a big difference. "Everything has become more efficient. I also like the cleverness around the barcodes. The system looks for the right frame. We no longer have to do that ourselves and therefore the error rate goes down. Yes, I really think this is progress!"

As of January 1, 2022, Bas Claassen (31) has joined TRYMA. Bas is account manager for Southern Netherlands and responsible for sales and relationship management. "I come from the technical industry and have always had an affinity with logistics and optimizing processes. Exactly there is also my value in all the conversations I will have in the market."