Range of sills increased

Both new standard profiles and a modular system

With ever-increasing demands on factors such as insulation values and wind and water tightness, the wooden window frame continues to evolve on a daily basis. Whereas practically anything can be made in wood, this is a lot more complex with non-wood sills. Ekosiet Products from Dodewaard therefore expanded its range of NEO sills with both new standard profiles and a modular system.

As desired by the market

The expansion of the range comes from industry demand. Someone who knows the current issues is Jeroen van Dijk, who joined Ekosiet Products this spring as commercial-technical director. Van Dijk: "In my previous position at Leitz-Service, I set up the machining centers of carpentry factories. During these processes, many new profiles were devised to improve the insulation value of window frames, for example. These were great solutions, but they regularly got stuck on the profiles of the sills until contact was made with Ekosiet Products! They were open to my ideas. It's all the nicer that I can now implement the new systems myself at Ekosiet Products."

Meanwhile, the company has devised profiles made of fiberglass-reinforced plastic instead of aluminum. In this way, a thermal bridge is prevented and thus improves the insulation value of the sill and thus of the entire frame.

New profiles

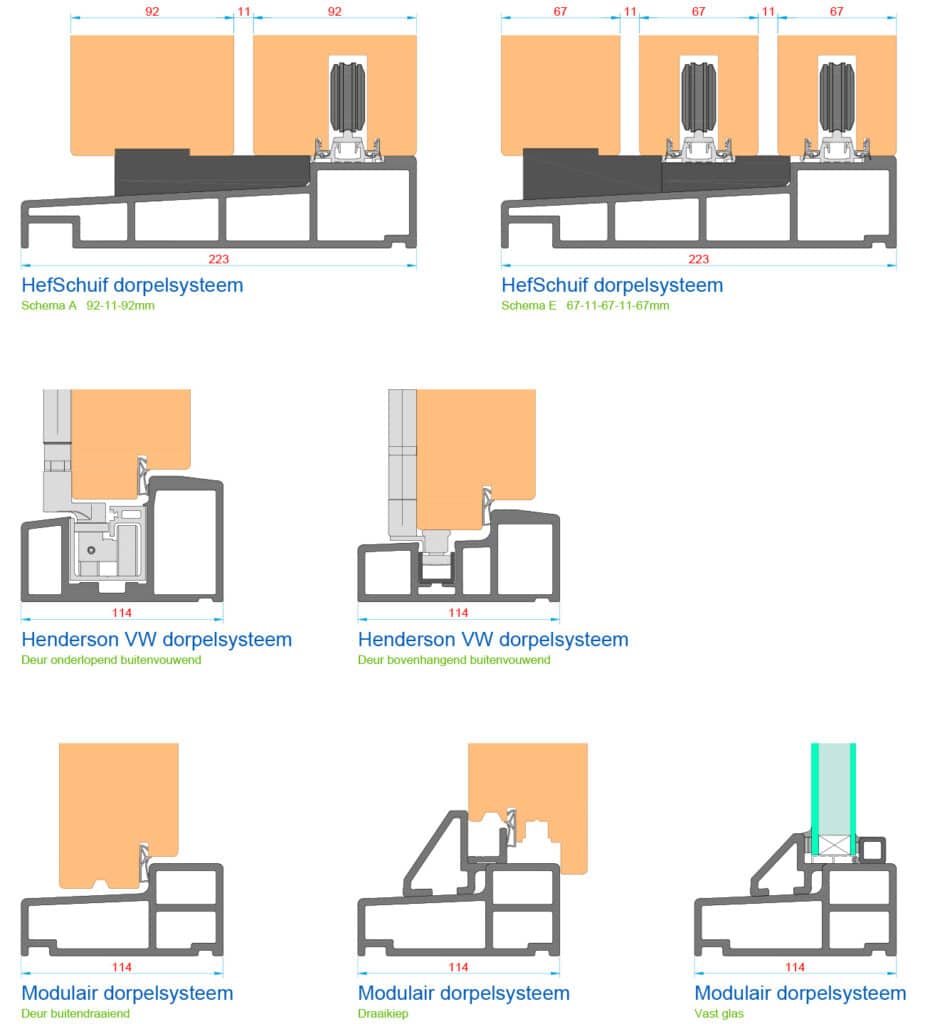

Ekosiet Products' NEO sills consist of a fiberglass-reinforced plastic. Van Dijk: "These strong, wear-resistant sills have good insulation values and the coefficient of expansion is zero. These are ideal properties for a sill for a folding wall, for example. One of the new systems is therefore a NEO sill suitable for a Henderson folding wall fitting." The sills are available in both bottom-hung and top-hung versions and can be designed for both interior and exterior folding walls.

Ekosiet Products also has several options to offer for sliding doors. For example, the company developed a lifting sliding door sill of 223 mm on which thick doors up to 92 mm for triple glass can be applied or, for example, doors of 67 mm but for scheme C or E.

In addition to the folding wall and lift-slide door sills, Ekosiet Products recently added a front door sill with rebate 67 mm to its standard range. This sill makes it possible to apply thicker doors and an even thicker glass package (triple glass) next to them.

Modular system

Van Dijk: "We also developed a new modular system that makes it possible to make virtually any sill for 139mm wood thickness, whether interior, exterior or lift-slide. Another advantage of the system is that different compartment fillings can be applied to the same sill. From fixed glass to exterior doors to tilt-and-turn; all on one sill and all at grade."

This new, modular system, at the same time, is rapidly increasing the combination of neuts. Ekosite Products is investing in a new, automated production method for the neuts to meet this demand as well. More on that later!