Making frames faster with durable new sill system

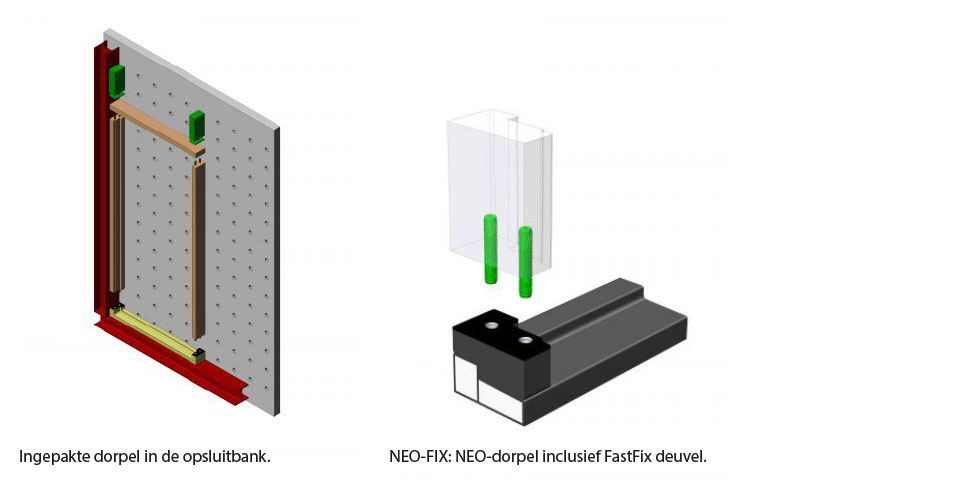

Ekosiet Products has been a manufacturer and supplier of lower sills to the frame industry since 2015. The Dodewaard-based company has been highly automated over the past year and is a fine example of a supplier that adds value to its customers. The latest addition to their sustainable repertoire is the Ekosiet NEO-FIX®, a KOMO certified combination of the previously developed Ekosite NEO sill® and the FastFix® dowels.

"Our Ekosite NEO sill® we introduced to the market less than three years ago and it is doing very well with our customers, the carpentry factories," begins Hans Kroon, general manager of Ekosiet Products.

"This sill is lightweight, consists of seventy percent recycled material and is insulated as standard which means the sill has very favorable insulation values with a Ufr value of 0.95. In addition, the sill is aesthetically pleasing with the appearance of artificial stone where the neutral and the sill are made of the same material."

"We have now combined this sill with the FastFix® dowels. About a year and a half ago, Ekosiet Products acquired Winfix, the inventor of this dowel, and from that, this concept was born.

FastFix® dowels are one hundred percent made of recycled ABS plastic, the thermoplastic from which, for example, Lego blocks are also made. The big advantage for the joinery factory is that the sill is already mounted to the frame on the locking bench rather than only during the final assembly. Per sill, that saves a considerable amount of time."

Profit for lumber mills

"The added value is mainly in the process," says Roger Daems, manager of sales. "Our sills are in fact part of the frame, which is why we chose to approach them in the same way. The gains for the joinery during assembly are multiple. The installation of intermediate laths on frames with multiple posts is no longer necessary because the sill ís the spacer. Cavity laths can already be applied directly to the sill during pre-assembly and, thanks to the clever FastFix® dowels you can mount without screws and dowels. "Crown adds, "You see more and more wide window frames with sometimes up to six intermediate posts. Then you have to make five intermediate battens or set glue clamps five times. With the NEO-FIX® you then save half an hour, which in practice means you can get the job done with one less man. And in carpentry factories, the bigger the factory, the more minutes count, the more interesting NEO-FIX®."

Spraying along

Careful consideration was given to protection. Daems: "The sills are protected by a high-quality transparent film. As part of the frame, the sill can be taken through the foil in the paint shop. Afterwards, the frame including the door and/or glass can head toward the construction site where, during the construction phase, the foil acts as additional protection against construction dirt."

Window frames after painting.

Total concept

In recent years, Ekosite has invested heavily in a fully automated machine park, with ERP software at the front end and CNC-controlled machines in the workshop. There, composite foam is processed into sills up to six meters long with all the desired specifications the customer wants. Kroon: "You have to make NEO-FIX® see it as a total concept. Since the sill is already assembled in the pre-processing, that same sill must be able to be provided with all kinds of options. For example, we can deliver the sill including mounted locking pots, end fittings or protective caps. But also different types of rebates in combination with struts for example for double gapping, tilt-turn solutions or triple glazing including corresponding mounted glazing profiles. In order to manage all this and deliver even faster, we have developed an ordering tool so that customers can configure and order their sills according to exactly the right specifications. This data is passed on one-by-one to our processing machines; this is less error-prone, results in shorter lines and ultimately faster deliveries. "Where NEO-FIX® primarily focused on adding value to the lumberyard and its own process, the sustainable nature of the NEO sill, for example, offers® a strong selling point to the lumber mills that they can use to their clients. To wit, beautiful, durable and practical."