Toward 2030: plastic window frames with at least 50% recycled material

Profile suppliers and industry association work toward a circular facade industry

The plastic window frame industry faces an ambitious mission. Trade association VKG wants as many new plastic window frame profiles as possible to consist of high percentages of recycled material, with a target of 50% by 2030. "That's a serious step," says Edwin van Houten, VKG's branch manager. "And it's not something one party alone can deliver. It requires a broad, joint commitment to the Chain Agreement, through collaboration in working groups and within the Circular Facade Economy (CGE)."

According to Van Houten, it is important to emphasize that all VKG members are committed to this and each contributes in their own way. "We see a lot of variation in techniques, investments and material flows," he explains. "That is logical: every profile supplier has its own markets, products and technical capabilities. There is no one universal approach, but it is precisely this variety of solutions that makes our industry stronger."

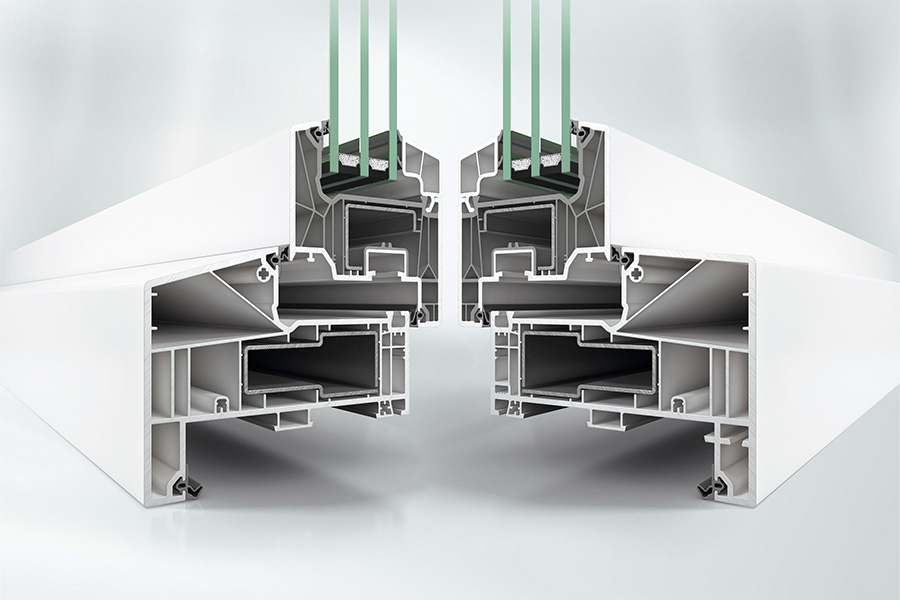

(Image: Schüco)

Recycling as a foundation

A key principle is closing the loop. "Plastic profiles now contain significant amounts of recycled material, but that percentage is not static," Van Houten explains. "It varies by type of profile, country and application: from a core of recycled PVC to profiles consisting entirely of recycled material."

Most importantly, all material streams are utilized. "So not only post-industrial residual streams and internally recycled material, but also post-consumer material from old windows and doors that are collected and returned to the production chain. The idea is: not to let anything go to waste. We want to keep raw materials in circulation as long as possible."

In the process, recycling processes have become increasingly sophisticated. In modern recycling lines, old plastic profiles are carefully collected, sorted, cleaned, dusted and ground into pure granulate. Thanks to innovative co-extrusion techniques, that recycled granulate can be processed into new high-quality profiles, often with a recycled core and new outer layers for optimal performance and appearance. "This kind of innovation makes it possible to guarantee quality without concessions," says Van Houten. "And the great thing is: plastic profiles can be recycled several times without loss of quality, as long as the formulas are managed and the stabilizers remain effective."

Innovations and alternatives

Clearly, the industry is investing heavily in recycling technology and closed material cycles. But circularity goes beyond recycling. Many manufacturers are also betting on extending the life of products, designing for detachability and avoiding material combinations that make reuse difficult. "Plastic window frames have a lifespan of about 50 years, making them last longer in the built environment and then suitable for reuse. So raw materials can theoretically remain in circulation for up to 500 years," Van Houten said.

"There are also innovations where fossil raw materials are partially replaced by bio-attributed PVC," says Van Houten. "That is PVC where part of the petroleum use is replaced by bio-based, non-fossil raw materials. Alternative fillers with a low or even negative CO₂ balance are being worked on at the same time. The goal is always the same: to reduce the environmental impact of plastic window frames as much as possible."

Transparency and certification

VKG and its members value transparency about the sustainability of their products. "We support our members with the VKG Recycling System, which now achieves up to about 90% CO₂ reduction compared to new production," Van Houten explains. "In addition, we see that members have certified their closed cycles, working with recognized labels such as EuCertPlast and VinylPlus. Many profiles are also suitable for international sustainability standards such as LEED, BREEAM or DGNB. And with LCAs and EQIs included in the National Environmental Database (NMD), manufacturers can demonstrably substantiate environmental impact."

Working together for the future

According to Van Houten, the road to 2030 requires continuous innovation and cooperation. "We work within VKG with working groups in which profile suppliers, manufacturers and resellers together discuss bottlenecks and develop solutions," he says. "In addition, through the Circular Facade Economy (CGE), we are pulling together with other facade materials industries to jointly develop circular standards and further close the loop. This trajectory is supported in part by the National Growth Fund and the concluded Chain Agreement."

Van Houten emphasizes that this is not a mutual competition, but a joint mission. "All VKG members are taking steps that suit their own situation and products. Every contribution is valuable and brings us closer to that ambition to use at least 50% recycled material in plastic window frames by 2030. It is an ambitious goal, but with the combined efforts of the entire chain it is certainly achievable."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met VKG - Vereniging Kunststof Gevelelementenindustrie.

Contact opnemen

Contact opnemen