New 5-axis machining center in the spotlight

For more than 25 years Emmegi was represented in the Belgian and Dutch markets by its own reseller, but in October 2021 the machine builder founded Emmegi Benelux. Thanks to a new team of technicians and salespeople, this subsidiary provides even better customer support not only in sales but also in after-sales service in Belgium, the Netherlands and Luxembourg. One of the machine builder's showpieces is the new 5-axis CNC machining center Comet R6 HP for machining profiles or parts in aluminum, PVC, light alloys and steel.

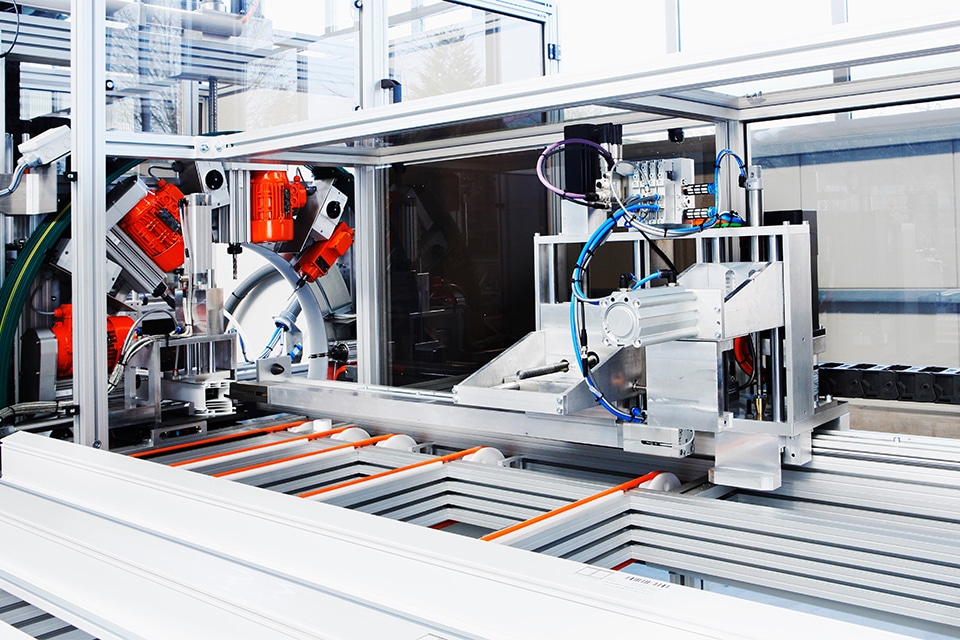

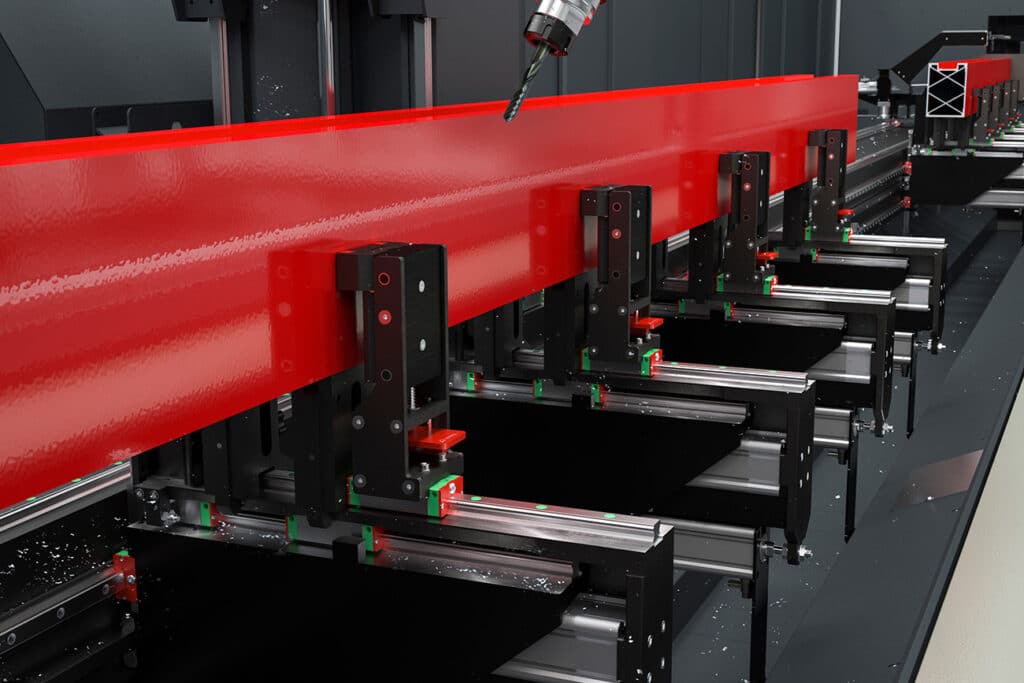

Accurate, robust and efficient, the innovative Comet R6 HP also stands out for its elegant design, quality, choice of materials and attention to detail and finish. Consequently, this machining center scores highly in technical and functional terms. For example, it is equipped with a powerful 8.5 kW S1 electrospindle with high torque, which allows even heavy industrial machining.

A 10.5 kW spindle with encoder is optionally available for rigid tapping, further expanding its capabilities. The motor can rotate infinitely from -15° to 90° on the horizontal axis and from -360° to 360° on the vertical axis, allowing the electrospindle to perform machining operations on the top and on all side surfaces of the profile without having to reposition the workpiece.

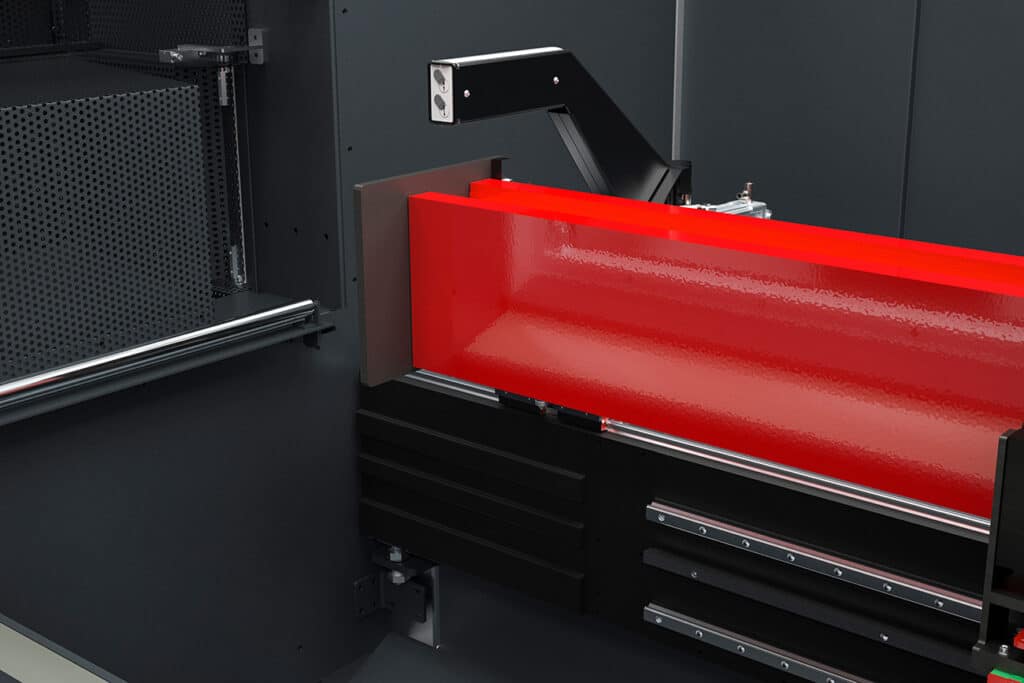

The large tool magazine is "convenient. It is integrated on the x-axis and located at the bottom and behind the spindle, which reduces the time required to change tools. This feature is especially useful when machining both ends of the workpiece. After all, there is no need to move in the direction of the magazine, since the magazine moves with the spindle. The innovative work mode minimizes machine downtime during workpiece loading and removal. Thanks to the two separate and independent work areas, it is possible to load or remove workpieces on one side while machining parts on the other.

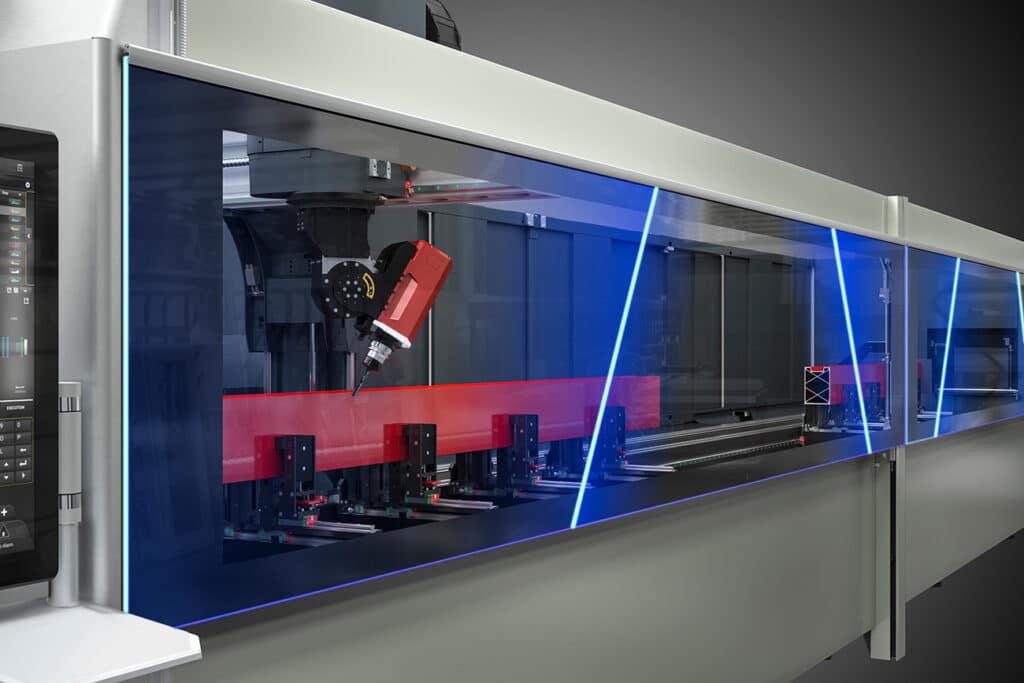

Lighting and colors, shapes and materials - nothing is left to chance with this new development from Emmegi. For example, the workspace is enclosed by a glass screen, which can slide down to allow easy loading of the machine. Thus, the operator also maintains a view of the workpiece at all times during the machining process. Glass is also easy to maintain and less prone to scratches and wear. The LED lighting on the front of machine, according to the color, displays the status of the machine and the progress of the machining process. The retractable tunnel in perforated sheet steel opens and closes as required, saving space in the workspace, and guarantees operator transparency.

The machine builder has also thought about the interaction between the Comet R6 HP and the operator. This is immediately evident, for example, in the operator interface, which is unparalleled in size and functionality. The 24" touchscreen display in 16:9 portrait mode (rotatable) can be used simply as a tablet. Further efficiency comes from the "invisible" part with the integrated H-Drill software that provides an even more intuitive and faster response to operator commands.