Tests in external laboratory prove energy efficiency of sandwich elements

Better thermal insulation than traditional 'hollow chamber' elements

Stadur's sandwich elements FrameTec and ProfileTec were recently subjected to tests by several independent bodies. Tests at the Schüco Technology Center showed that they score significantly better in terms of energy efficiency than conventional elements with hollow chambers. Complete building elements with these frame extensions were subjected to stability and other tests at the ift Rosenheim.

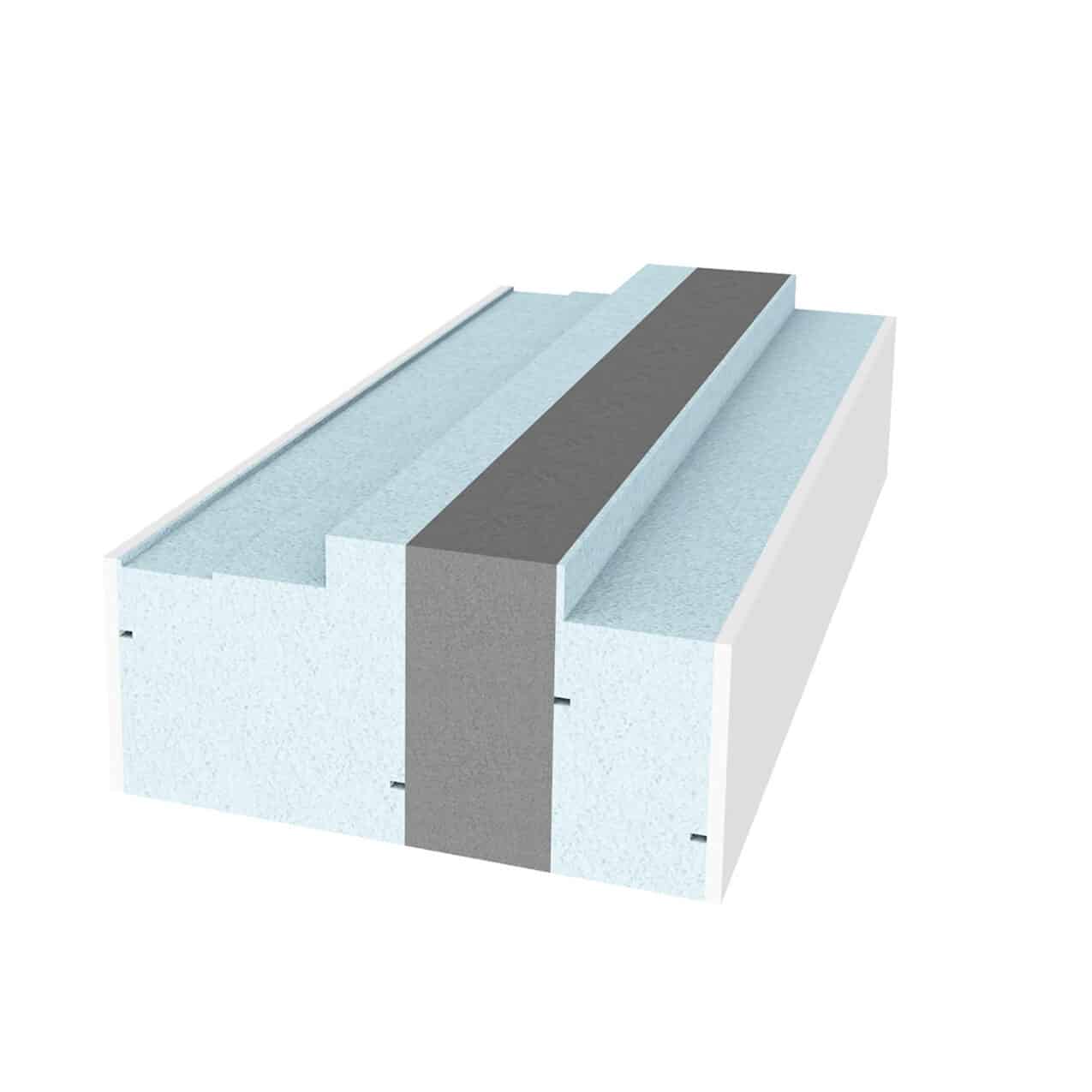

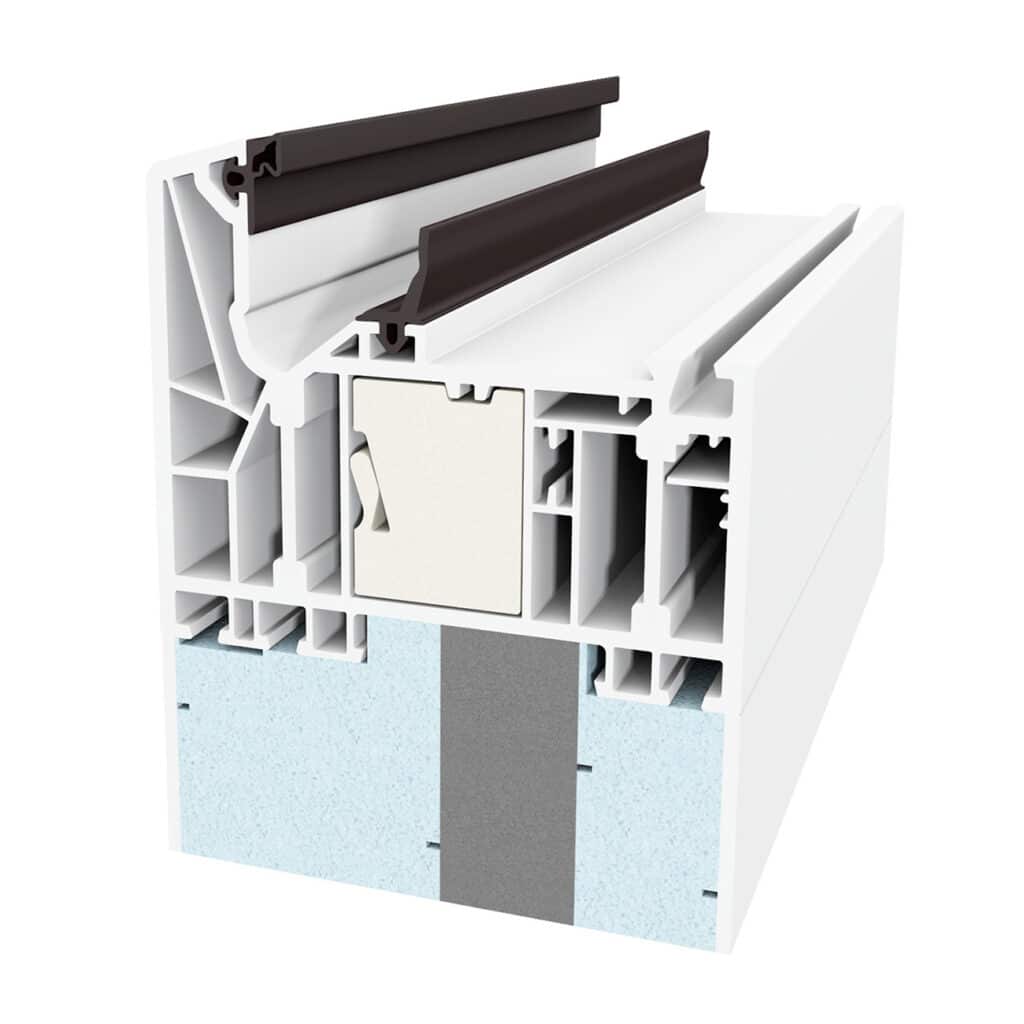

Stadur's sandwich elements FrameTec and ProfileTec are constructed from a core of StadurFoam and extruded polystyrene foam with a layer of Stadurlon plastic on both sides. They are used as frame extensions in the installation of roller shutter boxes and the connection of window sills or in the case of lift-slide systems, high windows and the installation of sills.

"Both products are available in different heights of up to 500 mm and in lengths of up to 7000 mm, enabling jointless frame widening even for large elements. They are characterized by a bending strength of more than 3.1 Mpa and an excellent pull-out value vertically of up to 6310 N and horizontally of up to 2815 N. This ensures a precise and flat connection for each profile," states Marc Nickel, sales manager construction for Germany and Benelux at Stadur.

"Furthermore, the material absorbs almost no water (< 1.5 %) and is completely rot-free. The panels are also light, which improves handling. Nevertheless, they can handle loads up to more than 1,000 kg/lm. Finally, thanks to the easy fastening with screws, without special tools, pre-drilling or doweling, one saves time and money."

High energy efficiency

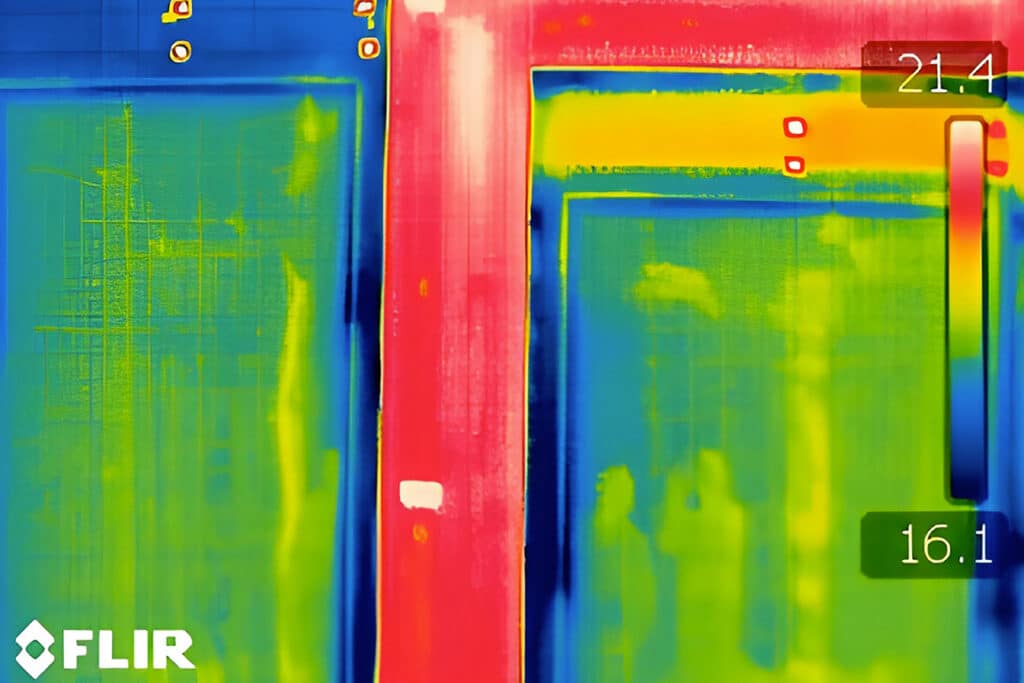

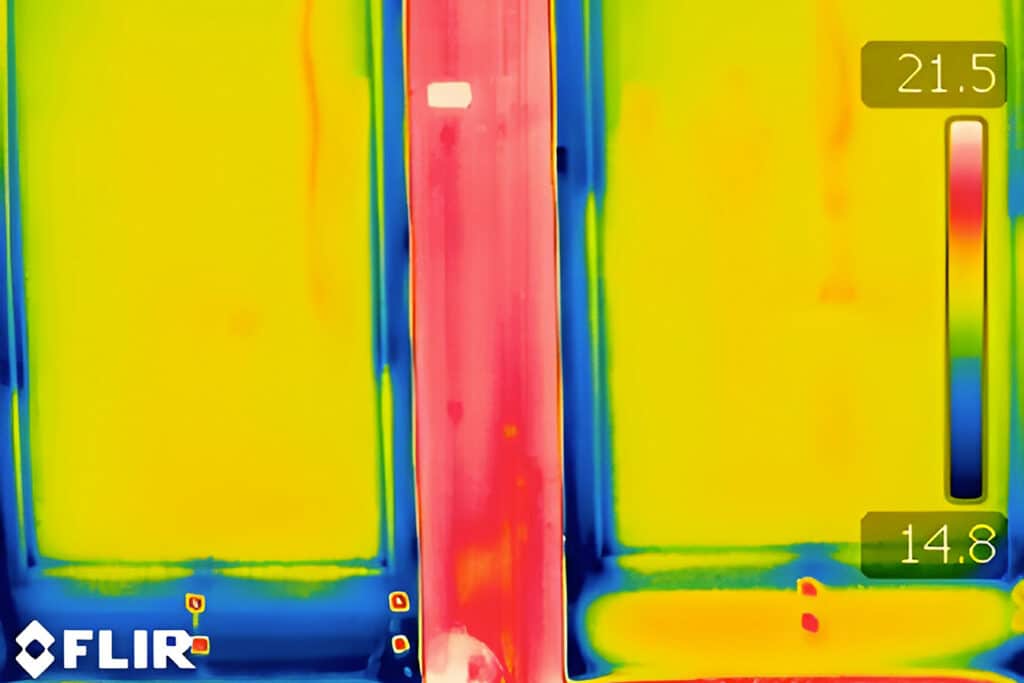

Manufacturer Stadur makes many efforts to provide architects, engineers and construction companies with the necessary test results from independent laboratories and external bodies. Thus, the FrameTec and ProfileTec sandwich elements were subjected to tests in the Schüco technology center in terms of thermal insulation. For this purpose, two sandwich-filled frames were set up in the test center's climate chamber: one with conventional profiles with hollow chambers, another with FrameTec. At an outside temperature of - 20° C, heat transmission was determined using temperature sensors and thermographic images. The arrangement with FrameTec frame widening scored significantly better than the other construction in this regard.

The arrangement with FrameTec frame widening scored significantly better than the other construction.

"Airtightness and thermal insulation are especially crucial in low energy buildings and passive building projects, both in new construction and renovation. Cold and thermal bridges between windows and building envelope must therefore be avoided at all times," Marc Nickel points out. "When developing FrameTec and ProfileTec, it was therefore very important that in winter the cold outside air could not penetrate, while in summer the heat was kept out. The high energy efficiency of these products benefits the end customers because they have to heat less in winter and cool less in summer."

Stability

To ensure maximum stability security for everyone, the sandwich elements were subjected to a series of tests at the ift in Rosenheim. The FrameTec frame extensions from Stadur were combined in building elements for this purpose with the screws and fastening brackets from SFS and the Living 82 window profiles from Schüco. These elements were successfully tested according to ift standard MO-02/1 2015-06 and ETB standard 1985-06. Other tests, in turn, demonstrated the excellent tightness with an air permeability class 4 according to DIN EN 12207 and a driving rain density class A9 according to DIN EN 12208.