Fire safety starts with the basics

HOW SMART SILLS CONTRIBUTE TO A SAFER BUILDING

Venster Techniek, developer and manufacturer of under sills for wooden and plastic window frames, has been researching for years how to further improve fire safety in construction. In doing so, the company literally goes to extremes: in the test environment sills are regularly exposed to fire to see what works and what can be improved. Through intensive cooperation with frame builders, profile houses, door manufacturers, industry associations and independent experts, Window Engineering continues to learn and innovate continuously in the field of fire retardation and fire safety.

London's Grenfell Tower fire in 2017 was a harsh wake-up call for Europe. What seemed to meet standards on paper did not always prove fire-safe in practice. Certified materials had not been used everywhere, and some alternatives proved insufficiently heat-resistant. Since then, regulations have been tightened in many countries, including the Netherlands.

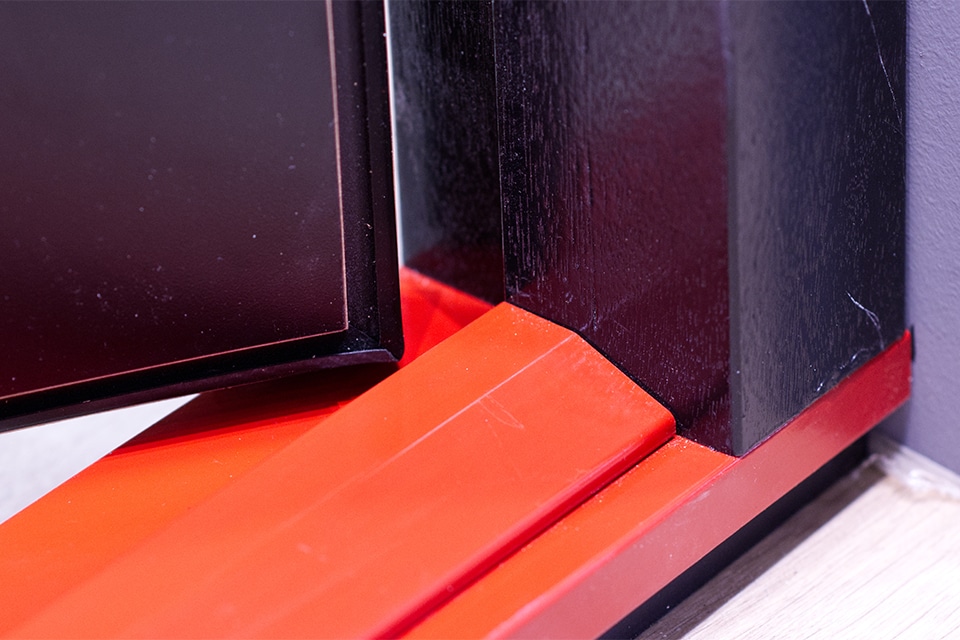

At the same time, the number of residential towers is growing in the Netherlands - buildings that demand a high level of fire safety. In this regard, the sill is also receiving increasing attention. What was once an inconspicuous building detail is now proving to be a crucial component in limiting the spread of fire. A well-designed sill literally helps cut off fire and smoke, contributing to a safe fire escape.

Fire delay

Fire safety is about more than preventing fire; it is about the set of measures that ensures that people can escape safely and that emergency services can respond effectively. An important part of this is fire spread: the speed and direction in which fire and smoke travel.

This is precisely where the sill makes a difference. Through clever material selection and construction, it can slow down the progress of fire. Thus, this small component proves to be a major factor in the overall concept of fire-safe construction.

What does the law say?

Dutch regulations - the Besluit bouwwerken leefomgeving (Bbl), based on NEN 6069 - stipulate that a tested product may be applied, or an alternative that demonstrably performs equally or better. For example, when a wooden sill has been tested, a heavier variant may also be applied without retesting, provided the performance is expertly substantiated.

For that reason, Venster Techniek cooperates with independent specialists such as DGMR Bouw BV. They assess test results, materials and constructions and, where necessary, draw up an expert statement.

Expert Statement

In October 2025, DGMR prepared an expert statement for the glass fiber reinforced sills (GRP) of Venster Techniek, including the VTD Prestige - 51, the VTD Excellent - 51 and the variants VTD BW30 54S, 40S and 54K. This expert statement is an official document prepared by a recognized expert (in this case DGMR) professionally assessing whether a particular product, in this case glass fiber reinforced sills, meets the applicable requirements, standards or expectations.

The statement is based on extensive fire tests the company conducted with Van Vuuren Grou BV and test institutes such as DMT and Peutz, among others. These showed that when used in Pico30 door constructions, the sills meet classification EW30: at least thirty minutes of flame resistance and limitation of heat radiation in both directions. Some configurations achieved even higher performance, up to EW63 and EI45.

Innovation through collaboration

The expert statement forms the basis for further innovation. Based on the results, Window Technology is working with a door manufacturer, a joinery factory, a project organization and a construction company to develop a new generation of window frames with updated lower sills for interior fire-resistant doors. This solution, now close to production, provides a robust and future-proof basis for fire-safe construction.

Collaboration is essential in this regard. Only by sharing knowledge, testing and developing together does innovation arise that makes a real difference. Fire safety is no accident - it is the result of insight, craftsmanship and teamwork.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Window Technology BV.

Contact opnemen

Contact opnemen