Produce and organize efficiently

Optimal long-term business processes thanks to customized service

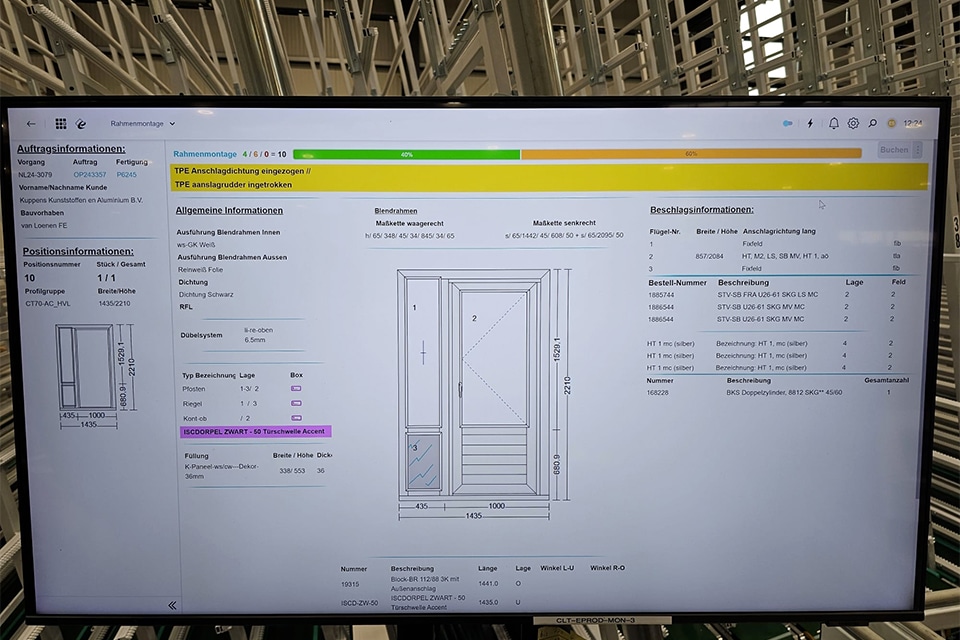

Manufacturing companies need to work and produce more efficiently and as a result, massive investments are being made in end-to-end digitization. Software house Klaes GmbH & Co. KG from Bad Neuenahr-Ahrweiler supports window and door manufacturers in digitizing their processes, but also sets standards for efficient control of machines and organization of production. With Klaes e-control and Klaes e-prod, the specialists offer software solutions that allow customers to optimize production processes over the long term and create efficient workflows.

Efficient control of machines for window production

Modern manufacturing companies face increasingly complex requirements. Custom windows, special dimensions and small series require flexible and efficient production methods for all types of material. Whether PVC, wood, aluminum or composite - Klaes e-control controls the machines efficiently and reliably. The software generates the required data and transmits it directly to the machine controller or a CAM system for seamless and fast production.

Based on a highly detailed master data system, intelligent data collection ensures speed and reliability even with complex components. Thanks to user-friendly operation, even changes to existing designs are no problem. With more than 30 years of experience in machine control, Klaes is one of the absolute experts in this field and ensures maximum precision and reliability in the production of all window and door systems with every machine control.

Organization of production and logistics

With Klaes e-prod horizon, the software house presents a new solution that seamlessly links production and associated aspects such as logistics and materials management. This innovative IT technology allows web, mobile and desktop applications to be fully utilized to organize production processes digitally and adapt flexibly to individual customer requirements.

A key feature of Klaes e-prod horizon is its high level of user-friendliness. Customers can make changes themselves, and also in a smooth manner, making support by Klaes optional in many areas. Moreover, the new architecture ensures that this support is done backwards, reliably and without interfering with the operation of the company.

With Klaes e-prod, companies have benefited from numerous advantages for years: Less paper and organizational time in work preparation, optimized organization of production thanks to direct access to up-to-date progress information and increased productivity thanks to a flawless data flow. Klaes e-prod also sets standards in the area of quality management. Inspections, maintenance and "bug fixing" - everything is centrally organized and automatically recorded. This ensures high process reliability with minimal effort.

Customized service for maximum efficiency

To ensure that Klaes e-control and Klaes e-prod can unfold their full effect, Klaes also offers a comprehensive range of services, fully tailored to the individual needs of each customer. The software specialists support companies not only during the introduction of the systems, but also far beyond - with a wide range of services that ensure optimal results.

The intensive analysis of existing processes is central to this. In close cooperation with the customer and the other project partners, Klaes develops customized concepts tailored to both the operational requirements and the existing machinery and system architecture. One must always be able to utilize the full potential of the systems, whether standard production or customization. In addition, employees receive hands-on training to ensure that all functions can be used efficiently. The direct line to the Klaes specialists guarantees quick assistance - even for customized modifications or complex challenges with systems in operation. In addition, Klaes offers regular updates, system optimizations and proactive technical support. Thus, customers always stay up-to-date and benefit from a stable and high-performing system environment.

With these innovative software solutions and customized services, Klaes ensures that digitization not only works, but actually creates added value in window and door production.