Combi concept combines wood-like door with non-wood frame

The versatility and appearance of wooden doors now combine with the advantages of plastic window frames

“This is what the designer likes; after all, with a wood-like door, any design is possible from modern, classic to the popular 1930s style.’ Speaking is Jan Kersten, director and owner of KEGRO DEUREN in Groesbeek. We are sitting at the table in Groesbeek with Jan Kersten, Ralph Peters, Head of Sales Internal Sales & Marketing and Marco van den Hoven, sales manager. The topic of discussion: the new KaiCombi door concept. The KaiCombi door concept makes it possible to apply wood-like doors in non-wood frames. ”Until now, that was a “bad marriage,‘‘ Kersten states. ”The differences between the materials were too great for such a combination to work well.“ However, KEGRO would not be KEGRO if a solution was not sought for that. And so it happened. The result is a concept that works and allows two worlds to merge in a perfect way.

Marco van den Hoven and Jan Kersten in the test center, in front of the wind and water tightness test stand.

Smart, thoughtful and perfectly applicable

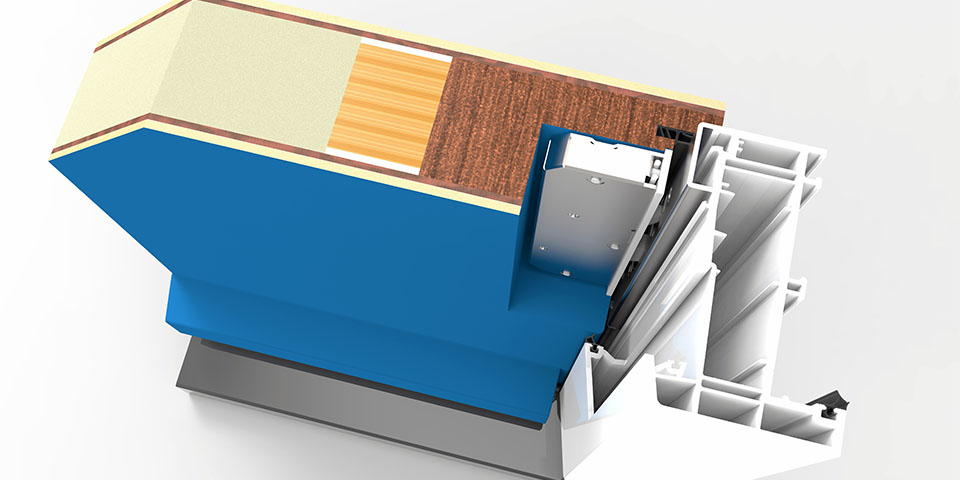

KEGRO DEUREN has provided technical documentation for each profile house. The manufacturer sees exactly what he needs to do to apply his non-wood frames within the KaiCombi concept. Van den Hoven explains, “We are talking about a very stable door leaf with a thickness of about 80 mm, adapted to the profile house in question. Always in the overlay version with profiling adapted to the profile. Completely newly developed hinges are used that are completely built into the door and are easily 3D adjustable when hung.”

All doors are delivered complete, with silicone seals, painted in a 3K coating, with fitted multi-point lock, three pre-assembled built-in hinges and fitted safety insulating glazing. “On request, door hinges, letterbox plate and cylinders are also fitted,” Kersten continued.

“The plastic window installer receives a comprehensive technical manual containing all processing instructions. This ranges from assembly of the corresponding sill that Venster Techniek developed especially for the KaiCombi concept, fixation of the frame in the frame frame, how to calculate dimensions of the door leaf to be ordered, to the dimensioning of the actions to be performed by the processor. Our technical documentation is also important because all tests and certificates are based on the aforementioned components.”

Impressive performance

Peters also speaks highly of the KaiCombi concept from a sales and marketing perspective. “Kai therefore stands for Kegro All Inclusive, indicating that we are trying to unburden everyone as much as possible. The concept focuses on new construction and the replacement market, provided the window frame is also renewed. It is therefore not intended for existing plastic window frames. In fact, everything is geared to each other to achieve the best results.”

And these results are worthy of note. Looking at the performance of the KaiCombi concept, we see that a water tightness of 600 pa, an air tightness class 4, a burglar resistance class 2, thermal insulation of the door leaf up to 0.6 W/m2K and Class 3B wind load resistance are possible. These are impressive results, which therefore did not come out of the blue. A tour of the test center at KEGRO DEUREN shows that most of the testing was done in house.

“We left nothing to chance,” says Jan Kersten in conclusion, as he shows us the test setup for wind and water tightness. “This concept meets all the requirements of energy-neutral building. For us, that was the prerequisite for bringing it to market.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Kegro Deuren B.V..

Contact opnemen

Contact opnemen