A good window frame needs a solid foundation

The sill is the foundation of a window frame. If the sill is not good, you will see it reflected in a number of things, including the squareness of the frame, the degree of air and moisture sealing, and the overall longevity of the frame. In our chilly country where we are exposed to unruly weather, the sill is literally a barrier to keep out drafts and moisture. Thus, the sill plays a crucial role in energy-neutral building. The Netherlands has a surprising number of companies that have made sills their specialty. The market for window frames is so large that anyone can earn a living with a sill they have developed themselves. Innovative as the industry is, care is taken to create sills that, with as little effort as possible, match profiles of medium and large profile houses as nicely as possible. The frame manufacturer himself chooses which brand of sill best fits his ideas of how a frame should look as a whole. Profile takes you on a bird's-eye tour of a number of prominent developers within sill technology.

Keep the sill dry with Ventistone

Idea is as simple as it is effective: The application of Ventistone profiles keeps the underlying window frame dry. The spacers between the profile and frame ensure optimal ventilation. Together, this ensures a permanently dry window frame. This provides a nice number of advantages. Ventistone fits within the policy of sustainable maintenance and maintenance costs are reduced by as much as 50%. This in turn has the effect of minimizing expensive painting and scaffolding costs. Wood rot damage and paint defects are a thing of the past. Ventistone has the look of wood, but the strength and durability of stone. Ventistone profiles are fire retardant and resistant to all weather conditions, the system is impervious to moisture. This environmentally friendly solution is suitable for application of a warranty period according to BRL5026 for 15 years. (Carpentry industry according to concept class III and IV.)

Waterproof and low maintenance sill systems from Holonite

Holonite sill systems connect seamlessly to wooden (Premax®), plastic (Kumax®) and aluminum window frames and are supplied with sealing gaskets and fastening screws with corresponding frame plugs. They all comply with the Building Code, DUBO construction and the Building Materials Decree.

All Holonite products are made of composite stone and therefore cold-bridge breaking. In the range we find: hybrid sills, where the lying part of the frame is durable and which prevents wood rot of the door and/or window frame thanks to the perfect connection of the neut to the frame style.

Other construction benefits include: industrial assembly (during frame fabrication), no adjusting and no grouting. The Kumax® Low-relief sills are a prefabricated sill system that can be installed under plastic window frames. The range of low-relief sills from

Kumax® Fits perfectly under both interior and exterior hinged doors. Premax® low-relief sills belong to a prefabricated sill system for the carpentry industry.

These sills are applicable to both interior and exterior doors, as well as double doors and lift-and-slide doors. The sills are machined to standard and specification. All Premax® low-relief sills are KOMO-certified and SKH tested and possess the basis to meet resistance class II and police mark Safe Living. Trimax low-relief sills are manufactured from high-quality fiber-reinforced composite with unique three-chamber profile, executed in a sleek design. The three chambers ensure optimal force distribution when loaded and are resistant to high compressive strength and therefore above average strength.

Indestructible sills made of fiberglass-reinforced polyester at Window Technology

Venster Techniek supplies various sills, glass and stop profiles and sealing profiles for both wooden and plastic window frames. A highlight of the range is the EEAL sill. What are the advantages of the EEAL sill? The frame and sill width correspond and everything fits seamlessly because Window Technique follows the profile specific to the profile house with this sill. These sills are made of fiberglass reinforced polyester, they are easy to work with and are delivered completely assembled.

The sills have double seals and can be glazed directly. The neuts on the sill differ for each profile house and ensure a direct and precise connection. Whereas a traditional plastic frame always needs an intermediate sill for glazing, this sill has a glass cap in line with the sill. So glazing can be done without the intervention of the unsightly intermediate sill. The result is more glass, less work and an aesthetic appearance.

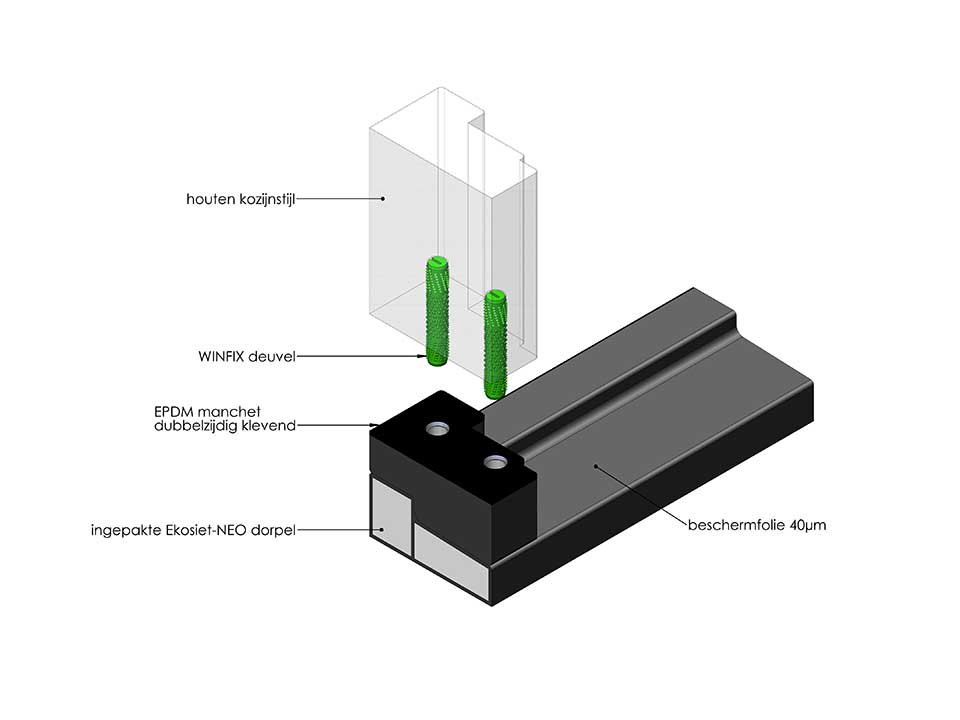

Durable sills from Ekosite products

All Ekosite sills are manufactured and assembled by the company from the base material to the finished product. These sills have the appearance of artificial stone combined with the strong properties of composite. A characteristic feature of Ekosite sills is their sustainability: for example, Ekosite-NEO consists of over 70% of recycled PET bottles, the Fastfix dowels even consist of 100% of recycled ABS plastic and can be recycled endlessly.

The FastFix dowel developed by Ekosiet is a patented plastic dowel specifically designed to give frame joints the necessary strength immediately after assembly. Both the sills and dowels are KOMO certified. A nice usp of Ekosiet products is NEO-FIX, the patented and KOMO certified sill system that can be included in the locking bench during pre-assembly.

The profit for the joinery during assembly is obvious. The installation of intermediate laths in window frames with several posts is no longer necessary since the sill is the also spacer. Cavity laths can already be applied directly to the sill during pre-assembly, and the clever FastFix® dowels you can mount without screws and dowels.

The optimally sealed home with sills from BUVA

BUVA homecare systems stands for carefree living comfort with the entire building chain in mind: from resident to client. The BUVA homecare systems are a collection of BUVA products that are coordinated in such a way that an optimal cooperation is created.

This leads to a sustainable healthy and safe living environment. BUVA supplies IsoStone sills within this concept, for both wooden and plastic window frames. The BUVA IsoStone® series of lower sills for wooden window frames is composed of glass fiber reinforced plastic (GRP). The profile consists largely of glass and has a textured surface due to a black UV-resistant coating.

The standard BUVA IsoStone lower sills already have a favorable insulation value in the base. Because the fiberglass-reinforced sill has hollow chambers, the air present functions as a perfect insulator. In the PUR-insulated version, the Ufr value of the BUVA-IsoStone sill is better than that of HR++ glass. The IsoStone sill series for plastic window frames includes nine strong, insulating sills made of lightweight fiberglass-reinforced composite. As a result, there is a perfectly fitting sill for all profile combinations.

Luvema supplies drop sills with a very precise mechanism

Aluminum and fiberglass sills are an important product group within Luvema's range of profiles. As a made-to-measure specialist, Luvema is reliable and fast.

Examples of sills supplied by Luvema include sills for folding walls from Centor and Henderson. Fire-resistant materials and lintels are also part of the product range. The latest generation of drop sills is equipped with a much more precise mechanism with a negligible tolerance.

In addition, the products comply with BS 476 standard and have international certification under UL94. Manufacturer Comaglio therefore guarantees 200,000 movements, good for 15 years of functionality under normal use. The range includes about fifty types that can be fitted to wood, plastic, aluminum and glass doors, both flush and surface mounted. In addition to standard lengths of up to 143 centimeters, special customization is possible up to a length of 300 centimeters. The surface-mounted variants can also be fitted with hoods that can be supplied in any RAL color as required. Furthermore, it is possible to mount the products through the seal, which significantly reduces installation time.

MACO is a 360˚ partner for sills seals and hardware

MACO produces its own sills, thus ensuring a synergistic effect between sill, seal and hardware. A conclusive whole with KOMO certification. Either 180 degrees around the window or door is safe and aimed at maximum comfort. In Zelhem both lift-slide sills, door sills and tilt-turn sills are produced to measure. MACO sills are easy to order via the online ordering tool and can be automatically imported via a Matrix import. The ordering process is thus fast and efficient.

That sills are an important product for MACO and the market is also proven by the fact that MACO has appointed a product manager for these products. Koen Vossers. In addition to sills, he is responsible for lift-slide solutions and seals. Matching sills, seals and hardware creates a nice synergy, according to MACO. Wind, water and drafts no longer have a chance to get in. MACO is a true 360˚ partner for sills, seals and hardware.

Innodeen sills with cradle to cradle certification

Innodeen supplies both sills for plastic and aluminum frames and for wooden frames. DTS VARIPRO sills are developed for and in cooperation with the plastic and aluminum frame industry. The VARIPRO system is modularly adaptable depending on the compartment filling and suitable for all known profile houses. The system is divided into two groups: VARIPRO BASIC and VARIPRO PLUS. For wooden window frames, there is DTS TIMBER. The Hollodeen, from which the DTS sills are manufactured, is fully recyclable and already consists of recycled material up to 90%.

Plus points are: wear resistant, unbreakable, 100% recyclable, circular and cradle to cradle. Also a high insulation value that prevents cold bridges. Furthermore, it is colored throughout and always has a good fit. DTS VARIPRO sills consist of recycled material for 90%. These properties therefore apply to both DTS Varipro sills and DTS TIMBER sills.