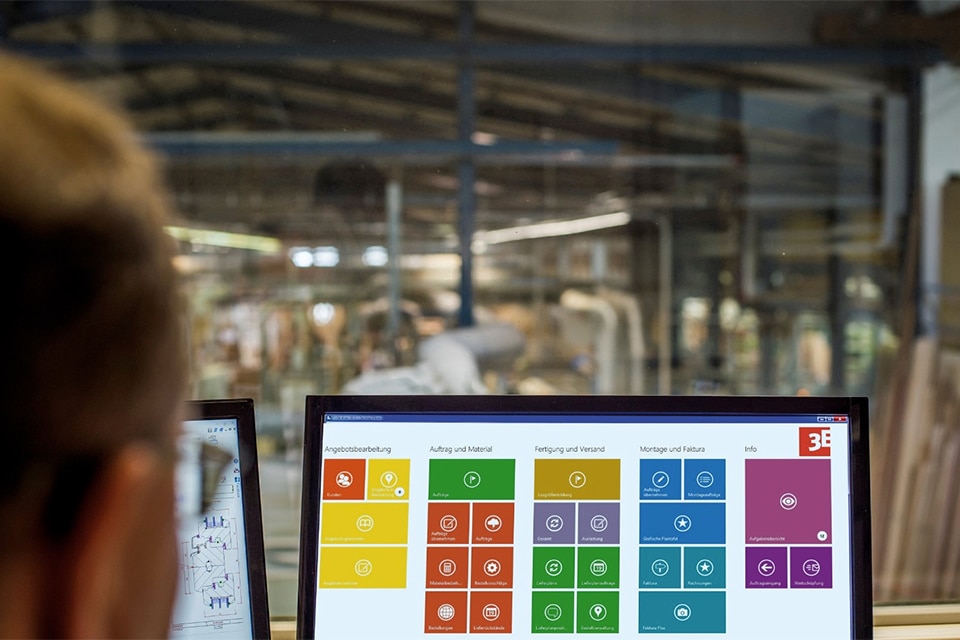

Software for fast and reliable production of doors

Digitization helps to improve and shorten processes and production processes transparently. The Horst Klaes GmbH, global market leader in the development of software solutions for manufacturers of windows, doors, curtain walls and conservatories, has innovative IT solutions for every level within a company, which efficiently support production. With the Klaes TürDesigner, doors in any material can be produced in a very flexible way. Thanks to the new multi-model, processors can now create and adjust door designs even faster.

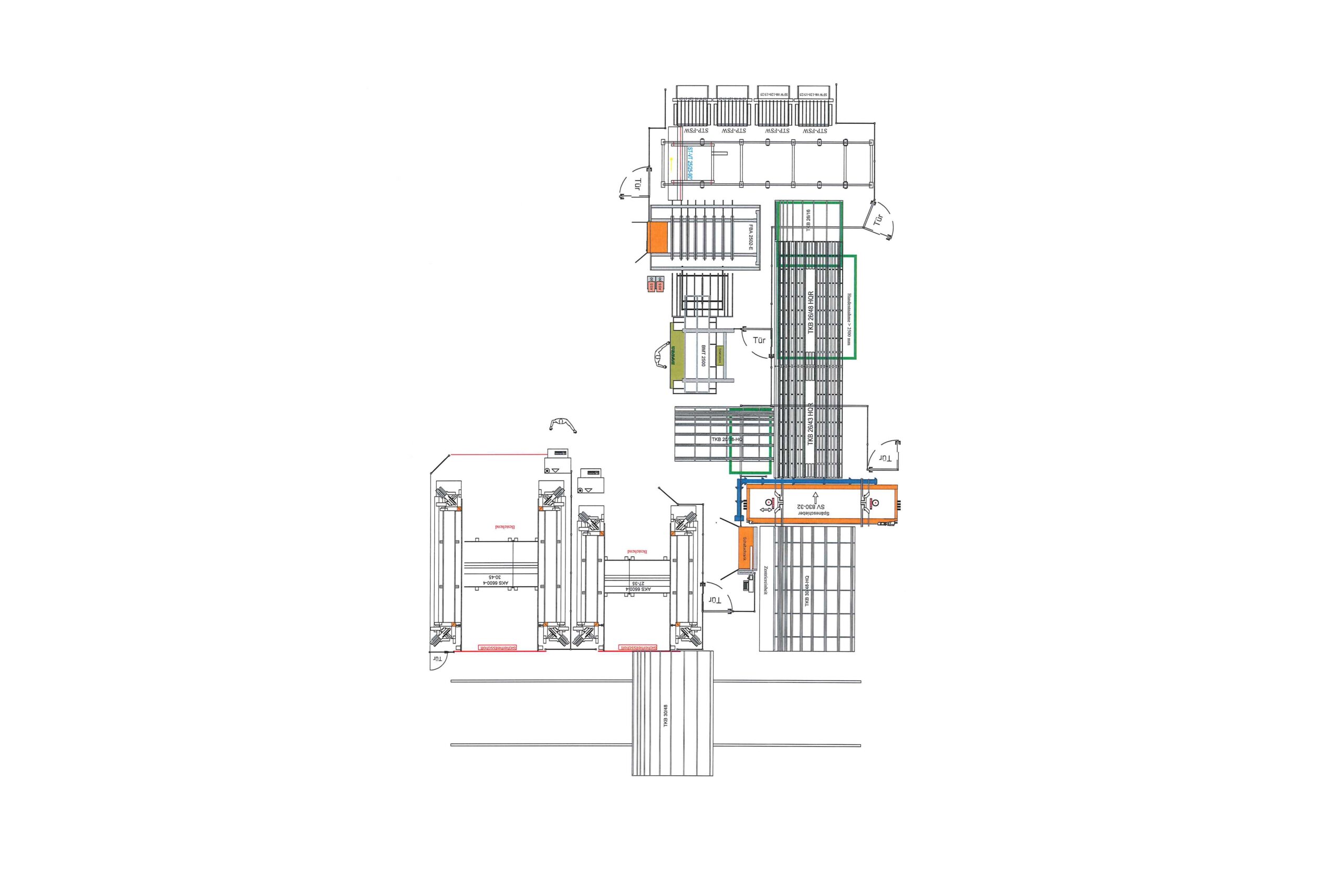

Klaes helps companies optimize their own business processes. Thanks to professional software, which fully manages organization and sales, planning and production, the most complex jobs suddenly become child's play. Quotations, orders, delivery notes, invoices; everything is displayed extremely clearly per production or project. Prices are calculated automatically and, based on capacity, delivery dates are displayed or the feasibility of the customer's desired delivery date is checked. After order confirmation, all desired data can be transferred into one or several production orders or positions from several offers can be combined into one order. The software controls the machines on the shop floor and all operations - whether cutting, drilling or milling - are fully automatic and simultaneous.

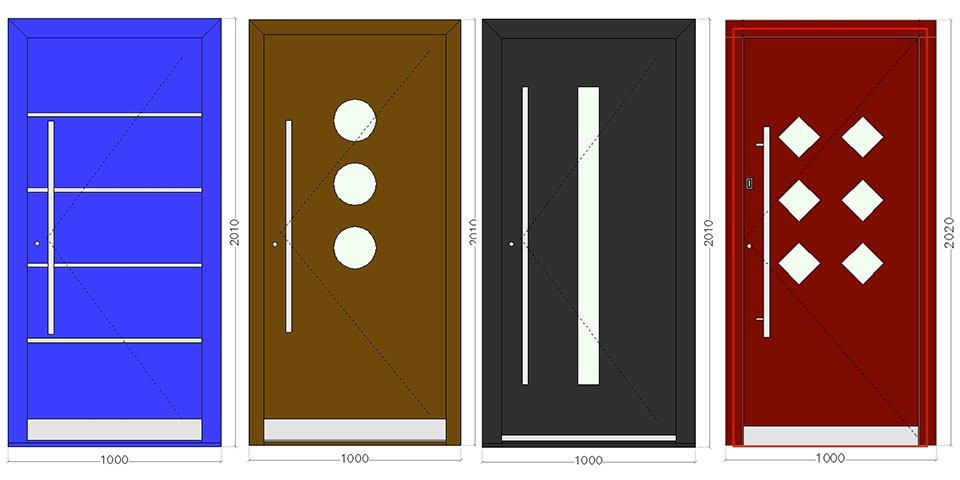

Klaes TürDesigner is a software that allows processors to design, calculate and produce classic and modern in an efficient and fast way.

Multi-model for Klaes TürDesigner

With the Klaes TürDesigner, doors, as well as window sashes, in both wood, wood-aluminum, plastic or aluminum are configured, visualized and produced in a very flexible way. All possible full-leaf and frame constructions are worked out together with the windows, if required, and follow the same production process. The innovative input system results in high reliability and speed in production. To further increase flexibility and production speed, an intelligent multi-model was developed. With a few minor changes to the parameters, the most diverse designs can be created. For example, details such as infill or recesses can be shifted, changed and reduced. The frequency can also be adjusted. As a result, the most important designs can be realized quickly and accurately, without the need for manual CAD drawings.

Simple and complete

Klaes TürDesigner therefore makes the design, calculation and production of full leaf and frame doors very easy. The integration into Klaes' ERP software also makes the solution extremely interesting for companies that only produce doors. This software is an all-in-one solution for the complete organization of business processes: from the design and automatic generation of production orders and detail drawings to supplying the data for controlling the CNC machines.

This is how quickly a multi-model is changed!

This example shows how easily such a model can be adapted for door production:

1. Adjust the door handle and make it 200 mm longer - the recess for the glass panel also adjusts automatically

2. Move this recess 100 mm to the left

3. Raise the bumper at the bottom 50 mm.

4. A pattern of infill cuts with a width of 16 mm next to the recess on the side of the

Fit hinges, automatically symmetrically distributed over the full height of the recess

5. Insert a vertical infill next to the recess, running automatically from the top of the door to against the butt edge at the bottom.