Accurate production with just a few clicks

Software connects workshop to office

Machines that know exactly what to do. It's not future music, because with Logikal, it has long been a reality. Orgadata's window and facade construction software provides a consistent connection between office and workshop. Anyone who designs with Logikal can control CNC machines and trimming machines directly from the system, from any manufacturer, quickly set up and instantly productive.

Office meets workshop

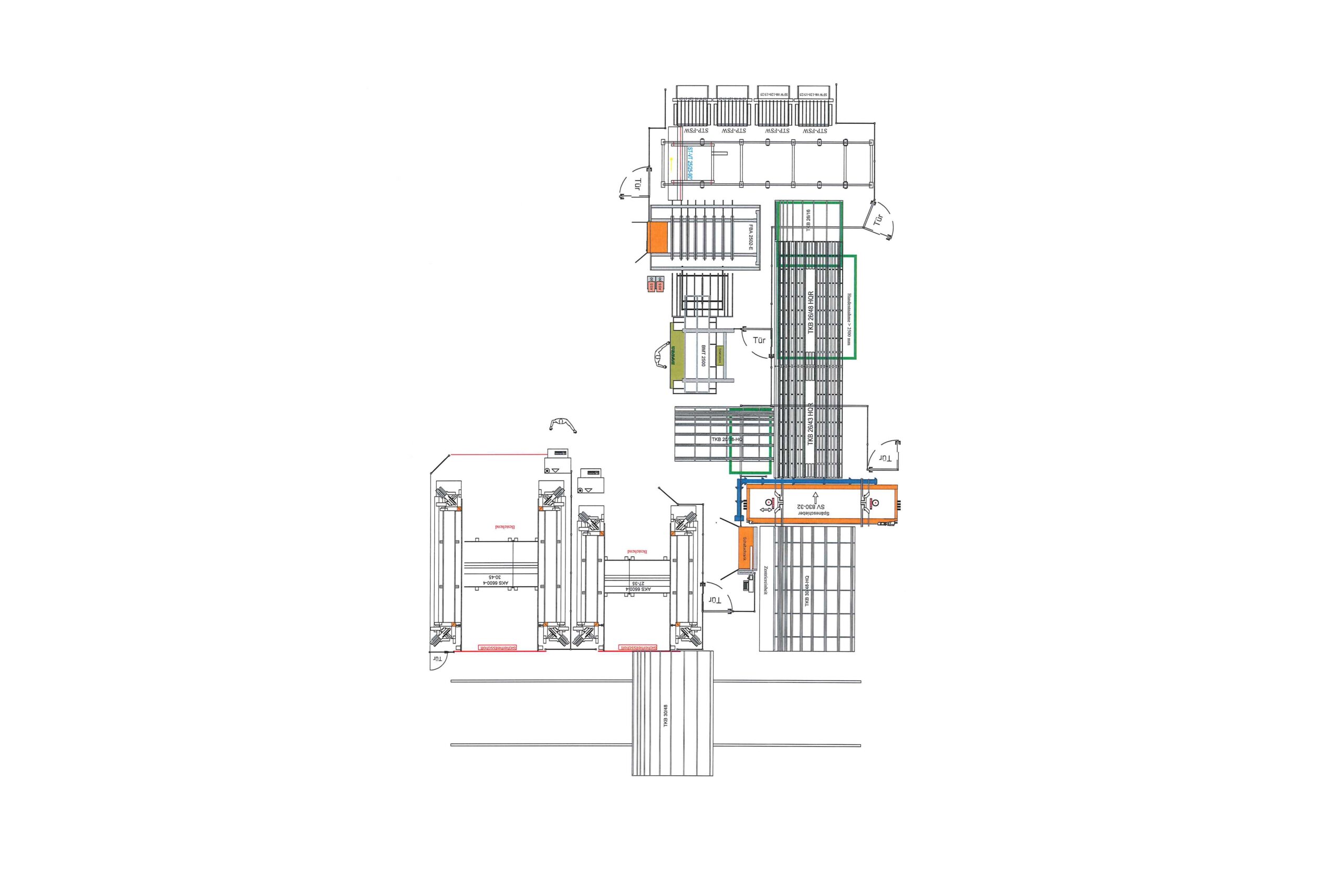

Whether it's a door, window or facade: whoever designs a part in Logikal also generates the necessary processing data in the same step. For example, if you add a lock, a hinge or a glass lath, the software automatically takes care of the corresponding milling, drilling or sawing. These processing operations are transferred directly to the machine without any manual reprogramming. This not only saves time, but also minimizes errors.

The software delivers more than just geometry: thanks to Orgadata's digital combination of components, profiles and accessories, Logikal knows the relationship between all elements. As a result, the machine knows exactly where to intervene and how, whether it is a slot size, a through-hole or a special milling contour.

Ready to use immediately

The interface to the machine is customized by Orgadata in conjunction with the machine manufacturer. This means that new machining centers can often be operational within a few hours. And: even more complex tasks such as special profiles or angled cuts can be performed immediately. This makes starting automated production surprisingly easy for many companies.

Usually a short training session is sufficient so that everyone involved can safely use the new connection. Thanks to the familiar user interface in Logikal, the input process remains clear for both designers and machine operators, regardless of whether individual pieces or series production is involved.

Efficiency that pays off

Direct machine control is not only a convenience benefit, but also an economic factor. Many users report that their machines stay productive up to 30 percent longer with the same staff effort. Because employees can concentrate on material flow instead of manually programming or reworking processes. In addition, Logikal allows efficient operation of multiple machines simultaneously. In many companies, two people are sufficient to simultaneously operate two machining centers and a saw. This is a decisive advantage, especially given the shortage of skilled workers.

All-in-one system

In addition to machine control, Logikal also offers everything from a single source for work preparation: work orders with profile cuts, component positions and processing are created automatically. They are supplemented by detailed parts lists containing all fittings, accessories and glasses, including part number, manufacturer information and quantity. Special solutions can also be easily realized, such as drilling holes for wall connections, which previously were often made only on the construction site. Logikal brings them directly to the workshop.

Definitely well planned

Another plus: the integrated "clash detection" prevents unwanted surprises. If a drill hole is too deep for the tool being used, the software gives a timely warning. This means production errors are detected early, even before chips fall.

Logikal is modular, is constantly up-to-date and grows with the company. Machine control is a powerful component for digitization in workshops of any size. Whether you are a series manufacturer or a specialized supplier, window and facade builders get their products in shape reliably and precisely with Logikal. And all with just a few clicks, right from the office.

Even more efficient

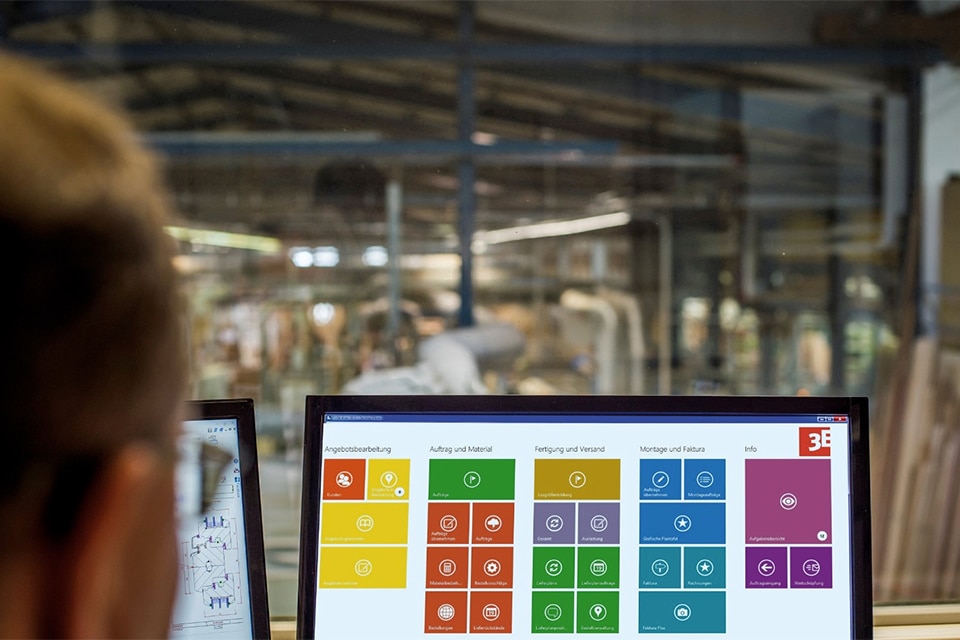

Anyone who also uses the Logikal MES production control system takes workshop organization to a new level. Production orders are distributed digitally and work steps are sent specifically to the appropriate station, at the right time and place. Employees can see on monitors exactly what needs to be done, and in case of problems, solution suggestions can be fed back immediately. This creates a transparent and lean process. Completely paperless and with maximum overview.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Orgadata.

Contact opnemen

Contact opnemen