Organize business processes digitally from A to Z

End-to-end digitization is the credo

More and more companies are opting for end-to-end digitization. Software house Klaes has been developing and delivering innovative IT solutions for years for intelligent digitization of business processes at window and door manufacturers, conservatory builders and other manufacturing companies. This does not just involve the production of window systems, but also other building elements, such as front doors and facades in a variety of materials. Klaes has a team of specialists in direct contact with customers and also demonstrates its software solutions at international trade fairs, such as BAU Munich, and other regional, national and international events.

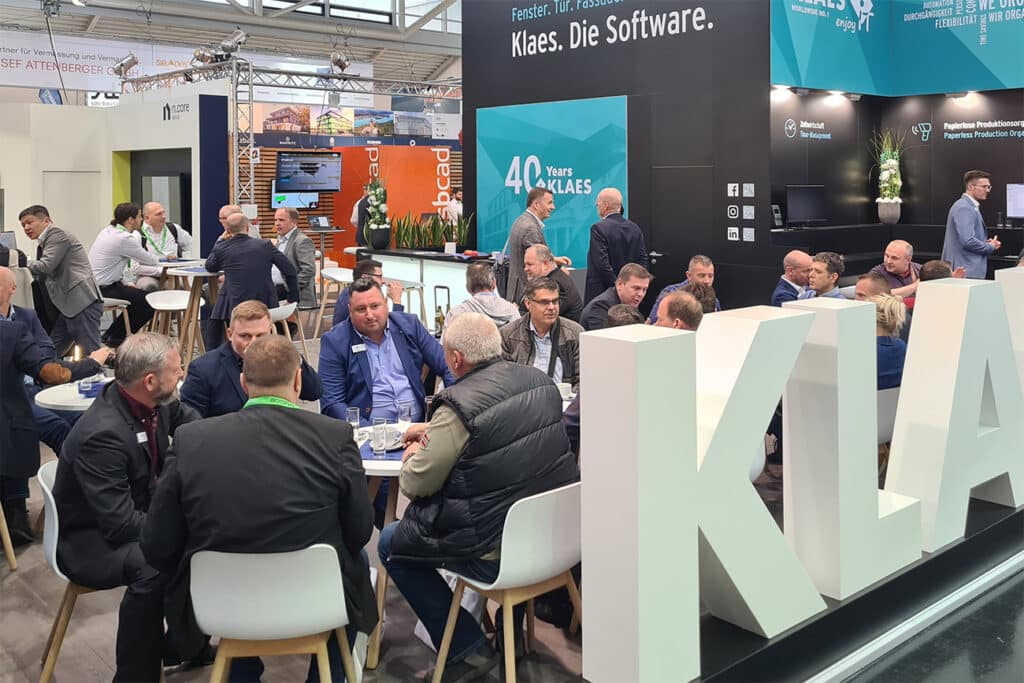

Successful exhibition participation

With 2,260 exhibitors and 190,000 visitors, BAU Munich scored high. This is clear evidence that international trade fairs are back on the calendar. BAU was also a great success for Klaes with an ideal mix of visitors: regional, national and international, customers, prospects, partners and also casual passers-by, who provided new approaches. Innovations such as 'Klaes zeit' and 'Klaes Montageplanung' attracted great interest. Klaes 3D' was also fully 'in the picture' - with facade builders but also with manufacturers of terrace roofs.

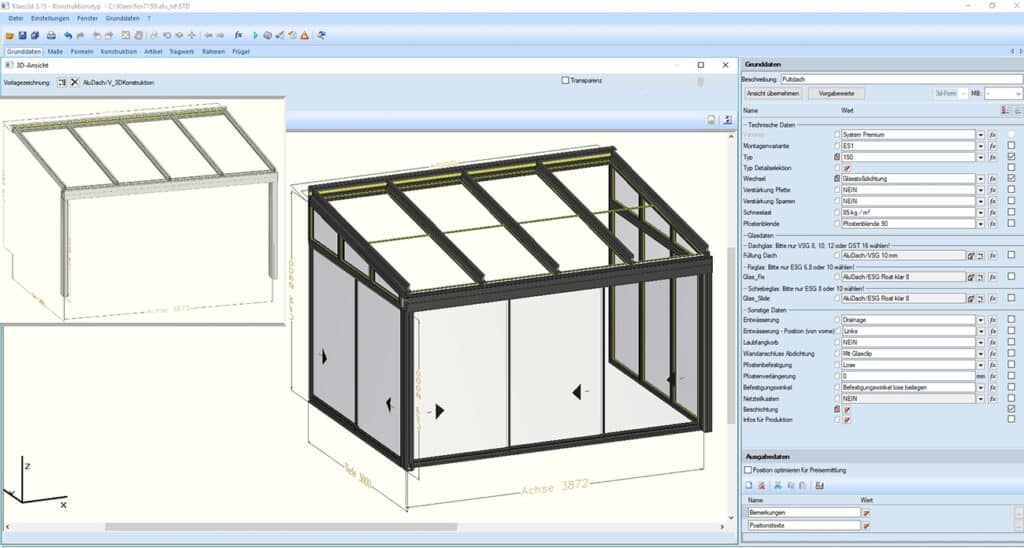

Easy entry at Klaes 3D

Thanks to Klaes 3D's intelligent input system for patio covers and conservatories, even complex constructions can be entered very easily via fields in a menu. Thus, one can work out complete conservatories with all desired details and the elements to be integrated in a few minutes. Thus, a complete 3D CAD design without drawing a single line. At the same time, aspects such as calculation or data for controlling machines are also immediately available.

Step by step - start with a patio cover

1 Adjust the construction method. For a freestanding model, end caps for gutters and gable connection, among other things, are automatically worked out. If you select the "Wall Left" option, flatter end caps are used. All dimensions are adjusted immediately. Here the wall attachment is removed and two uprights are automatically added.

2 Choosing other profiles. The profiles are replaced, along with the corresponding screws and connecting elements. If desired, also LED lighting, heat emitters or sensors for light, wind, temperature and rain, including drilling and cabling.

3 Add additional elements, for example, sliding systems, swing doors, folding systems, fixed elements, ..., and if desired, blinds and windproof screens.

4 When integrating leaf traps, drainpipes and other accessories, machining in different profiles, such as the uprights or gutter, is also added.

5 Customizing the glass roof. Based on what one enters, the profiles, components and operations are automatically adjusted. A glass roof can be converted to a slatted roof with tilting and even sliding slats in no time.

6 Enter dimensions. Indeed, one can enter these at the end, when everything is actually already done. The whole thing adapts immediately. Fittings and motors are also adjusted based on the changed dimensions and weights.

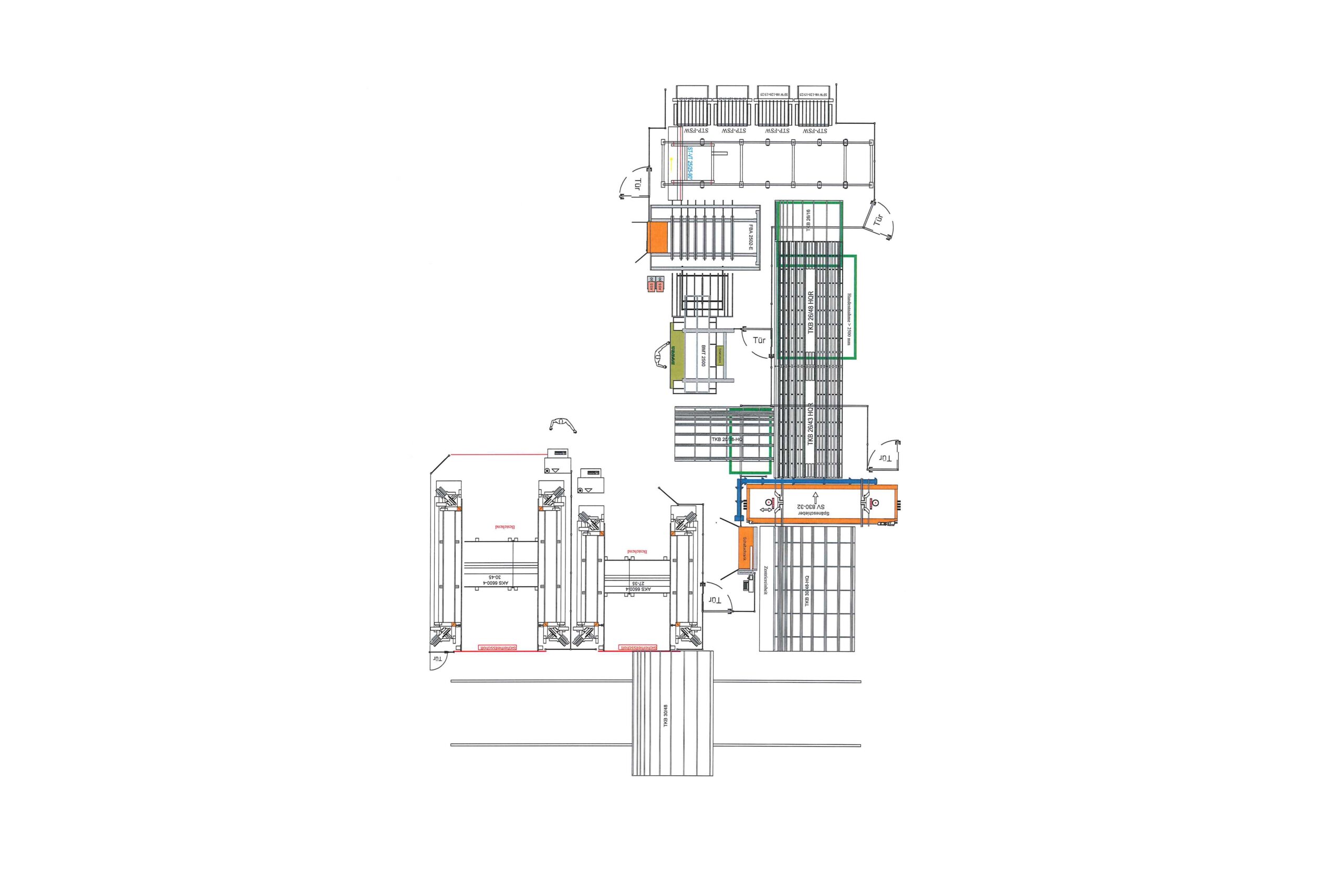

Event at a loyal customer

The company Anton Manhart, a loyal Klaes customer for many years, started building a new production hall for wooden windows in 2021 and equipped it with high-quality, digitally controlled machines. They also switched from Klaes vario to Klaes professional. Anton Manhart and his team are extremely pleased with the result and were only too happy to host Klaes' "Treffpunkt Fenster - Automatisierung im Handwerk" event at the beginning of May, to which fellow window manufacturers from Bavaria and surrounding regions were invited. During the event, visitors were also able to talk with the host and all the other partners involved - Adler (paints), Leitz (tools), Maco (fittings), Schuko (exhaust systems), Stemeseder (aluminum profiles), Weinig (machines) and Klaes for the software - about their experiences during the project and afterwards.