Optimize business processes thanks to digitization and analysis of production data

Customers have high demands for quality and delivery times. To respond to all demands, manufacturing companies must invest in efficiency and productivity of their production processes, reduce costs and minimize the error rate. Extensive automation and digitization of business processes can help optimize operations. With eluCloud, elumatec and elusoft offer a joint industry 4.0 solution for the digitization and analysis of machine and production data.

eluCloud is an indispensable tool for firms that want to produce quickly and efficiently and meet delivery deadlines. "This joint software solution from elumatec and elusoft records all data related to machines, parts and production, allowing one to access information from any location in real-time of what is currently happening in production and what has happened beforehand," says Bas Ladestein, managing director of elumatec Benelux BV.

"This allows one to track problems, analyze errors and optimize the production process."

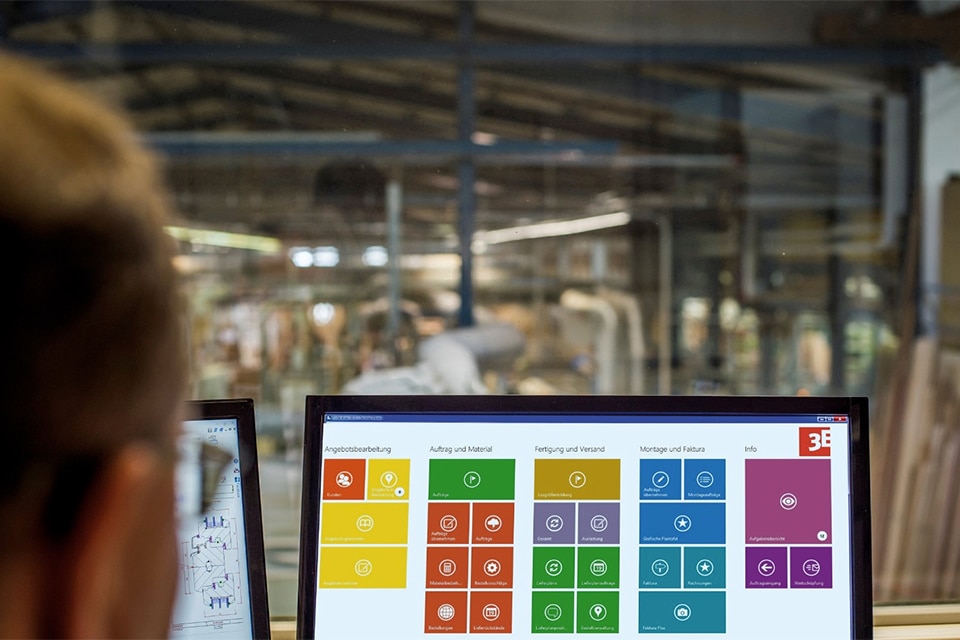

Among other things, the software visualizes data on pending jobs, machine availability and machine status, and allows production managers to use the available information from past jobs to analyze efficiency in machining a particular workpiece and, if necessary, optimize the workflow.

Different modules

eluCloud includes 4 modules and an App, allowing the functions to be accessed on a smartphone, tablet or laptop. "eluCloud-Monitor and -Server are basic elements, which one needs to use the software, while with the additional eluCloud-Analytics module the user can analyze the collected data and generate detailed evaluations of, for example, the efficiency of the machines or the progress of a machining job," the managing director continues.

"The eluCloud API interface provides seamless communication between individual machines or between machine and software. In this way, the data can also be integrated into calculation programs and ERP or MES systems."

eluCloud Monitor and Server

eluCloud-Monitor is the cornerstone of the software and is used to record data from the individual machines and productions: finished quantities, production times and speeds, run times of spindles, downtimes, interruptions, error messages, maintenance events, .... eluCloud-Server stores all the data so that it can be used for evaluations. This server was specially developed to integrate into an existing IT infrastructure and employees can access the information from their hardware. At a later stage, it will also be possible to work from a Web-based Cloud solution.

eluCloud-Analytics

Can the machinery handle more jobs or do I need to invest in an additional machine to do so? How much time did the machining of a particular piece take and how many workpieces were produced per hour or per day on one or all machines? How many tool changes were required to machine a particular workpiece? Those who want to make detailed evaluations to answer these questions should invest in the additional eluCloud-Analytics module.

"The user gets a dashboard and decides which analyses he wants to visualize. By analyzing a wide variety of data from production processes, one can optimize production technology and significantly reduce production time," Ladestein concludes. "This module allows one to determine the required production time for a workpiece or an entire job, which allows one to calculate future jobs more accurately. In addition, this module also helps with fault finding."

Ready for Industry 4.0

eluCloud is a handy tool for automating and digitizing production processes. elumatec and elusoft are thus opening further doors to Industrie 4.0, Smart Factory and "The Internet of Things. ′