Manage your warehouse the smart way!

Stock management indicates maximum and minimum quantities and automatically generates purchase signals. This usually ensures that there are never shortages : the so-called stock breaks. Moreover, in this way you are going to bring down excess sight stock without increasing the risk of shortages. The capital sitting in dead stock is thus released.

But everyone encounters it from time to time: the ordered parts have been delivered, but where are they now ? Still in the box in the entrance hall, at their place in the warehouse or already prepared for processing? Especially when volumes increase and storage space is tight, additional resources are required: practical stock management linked to warehouse management can help.

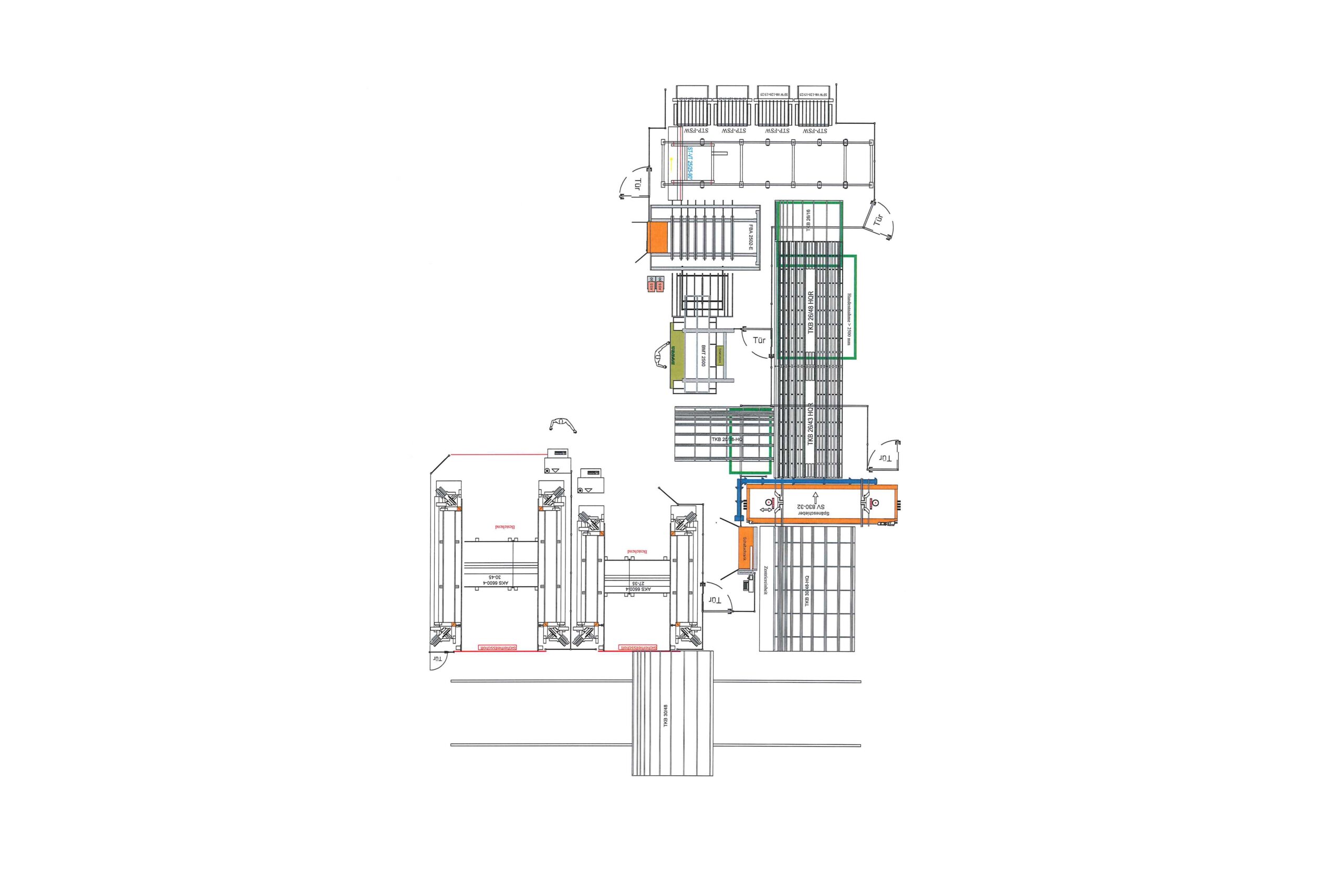

In warehouse management you go one step further than in inventory management: in inventory management you register that the items have been purchased, arrived, sold or already used, while in warehouse management you immediately assign a location to them. By working with clear locations in the warehouse you can expand the picking list of an order with the locations so that when collecting an order you no longer have to search.

Warehouse management....differentiate between stock and project items

- Stock items

With stock items, there is preferably a fixed location where you can find them and the location is set up for the type of material. This location can then also be permanently linked to the item in the software module. - Project articles

With project items or materials, which are ordered to the size of a project, space must be allocated to temporarily stock them until they are processed. So this type of items rotates very regularly. Here it is necessary to have enough space to keep them together to be able to find them back in an organized way. If there is no place to put them together, warehouse management is crucial to avoid a lot of searching.

Warehouse management....some tips :

- Map and name the different locations is : warehouse, corridor, rack or shelf. Approximate as closely as possible to the real layout and do not define more places than you practically use.

Typical example : the production floor is divided into several workstations and each workstation has its own grab stock. But if in practice it turns out that materials from a neighboring workstation are also used then it is better to just use one location for the stock on the shop floor. The material is either still in the warehouse or it has been "delivered" to the production floor.

- Create a location 'drop zone' : if you have a real warehouse with a clear location management, the material just delivered can be immediately entered as being delivered in the 'drop zone' and a final location can be assigned to it afterwards. This avoids a lot of confusion about the delivery itself.

- Map the number of goods in the vans : the vans of the placement teams are also a warehouse location. So you can perfectly monitor how much silicone is consumed by the teams, for example.

Conclusion

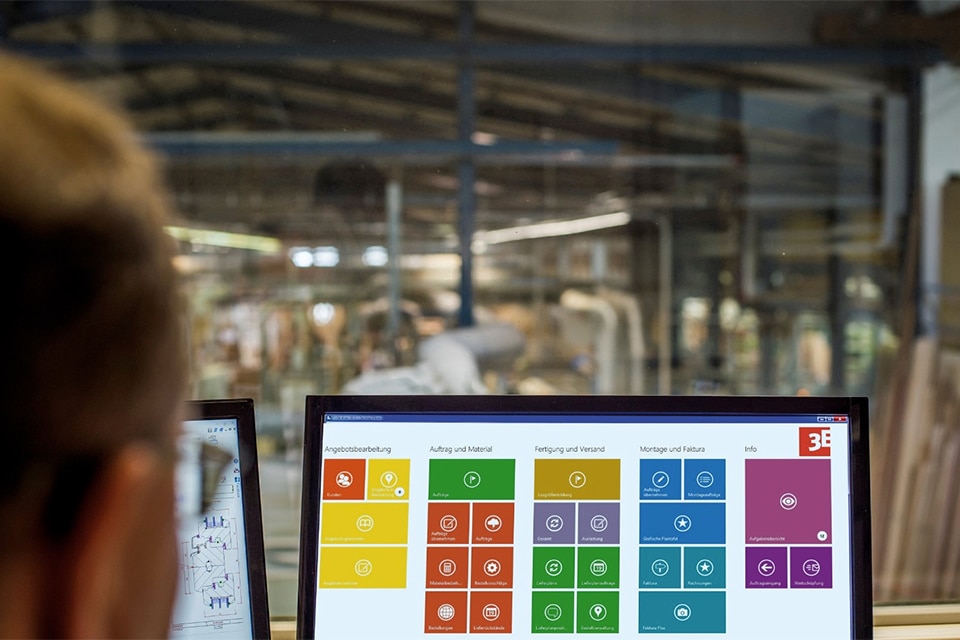

A solid warehouse management software module speeds up and controls the logistics process. Warehouse software is indispensable for joiners who want to manage their warehouse in an efficient and smart way. Without too much fuss, but with a complete overview of all articles and materials with the exact location.

Interested? Contact Techwin.