Greater efficiency, lower costs and a future-proof IT environment

Consistent digital processes ensure maximum efficiency and productivity

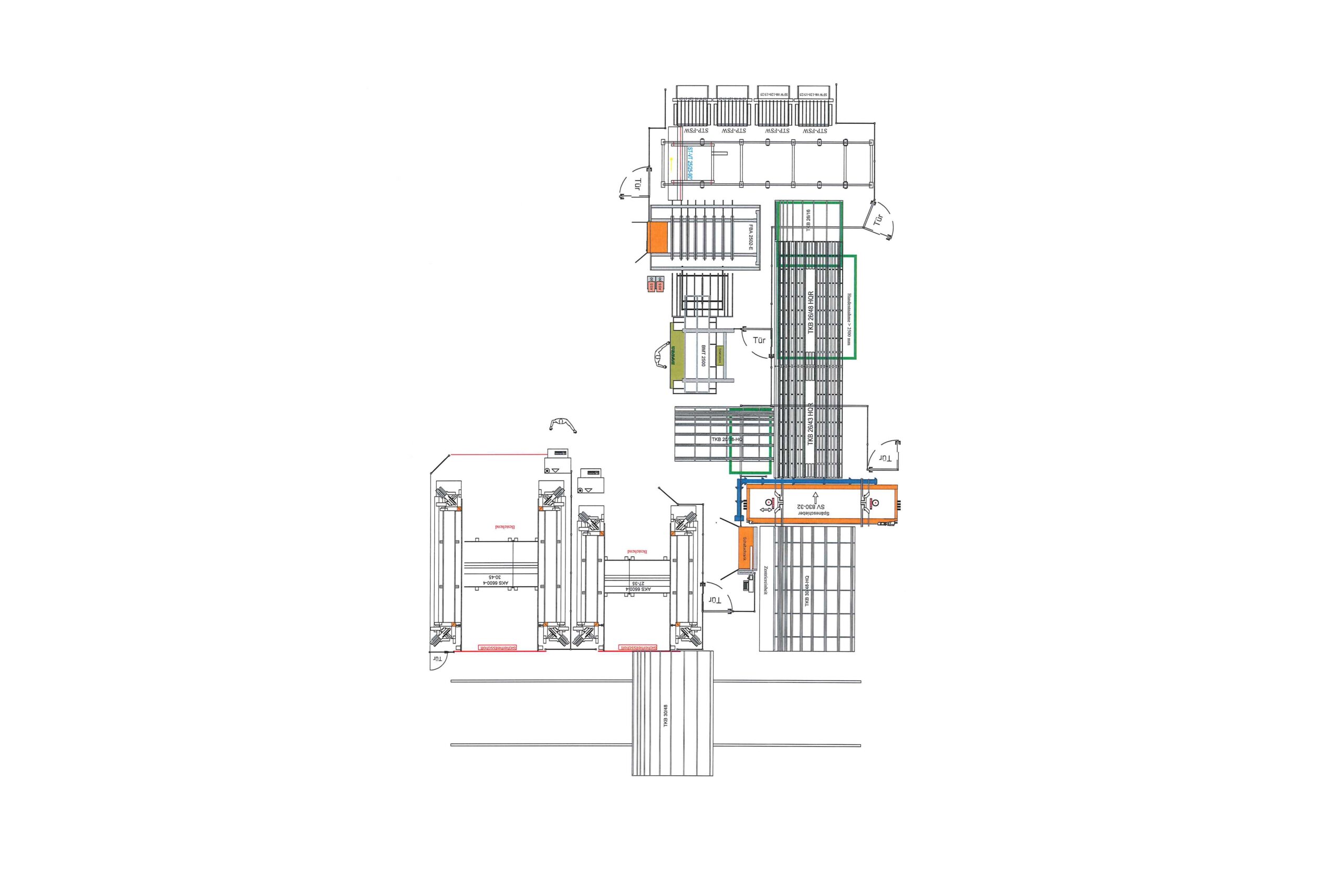

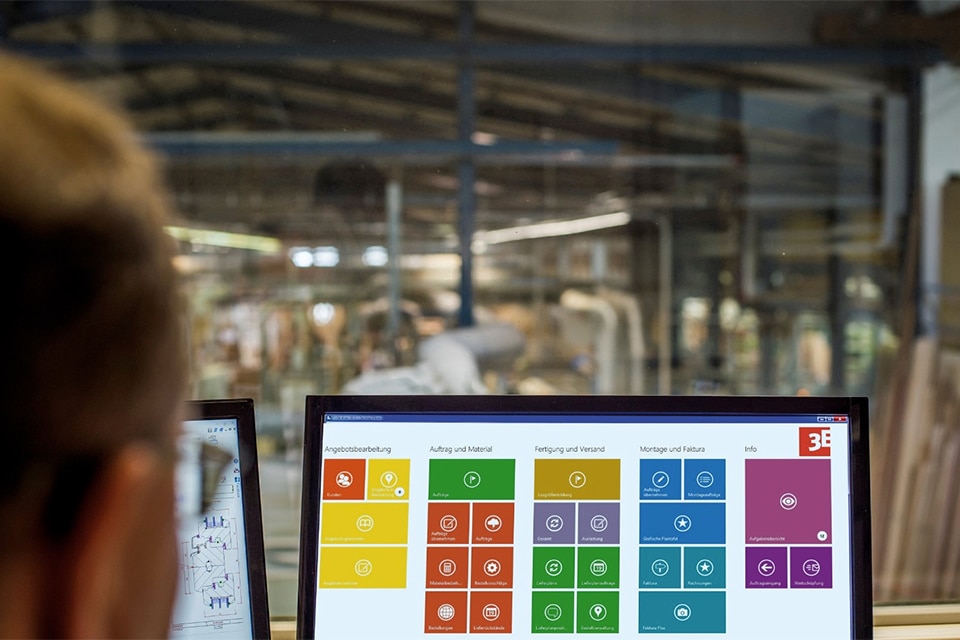

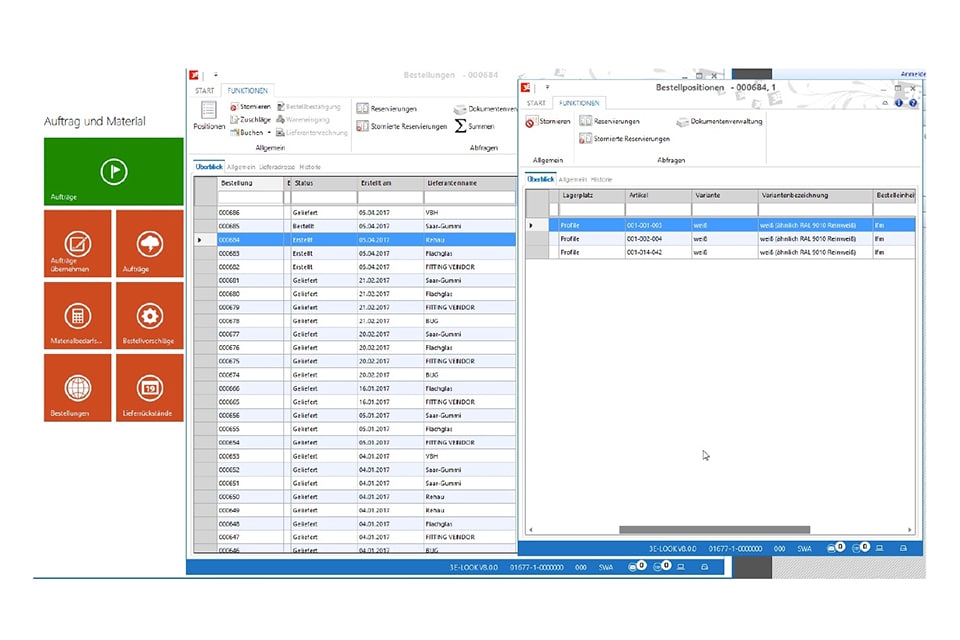

With its 3E-LOOK platform, the South German software specialist 3E Datentechnik GmbH is setting the standard in digital window production. The flexible solution enables complete digitization and automation of processes: from quotation preparation, planning and production to delivery and assembly. Networking, interfaces and the seamless connection to third-party systems ensure greater efficiency, lower costs and a future-proof IT environment for the customer.

More efficient processes thanks to integrated web configurators

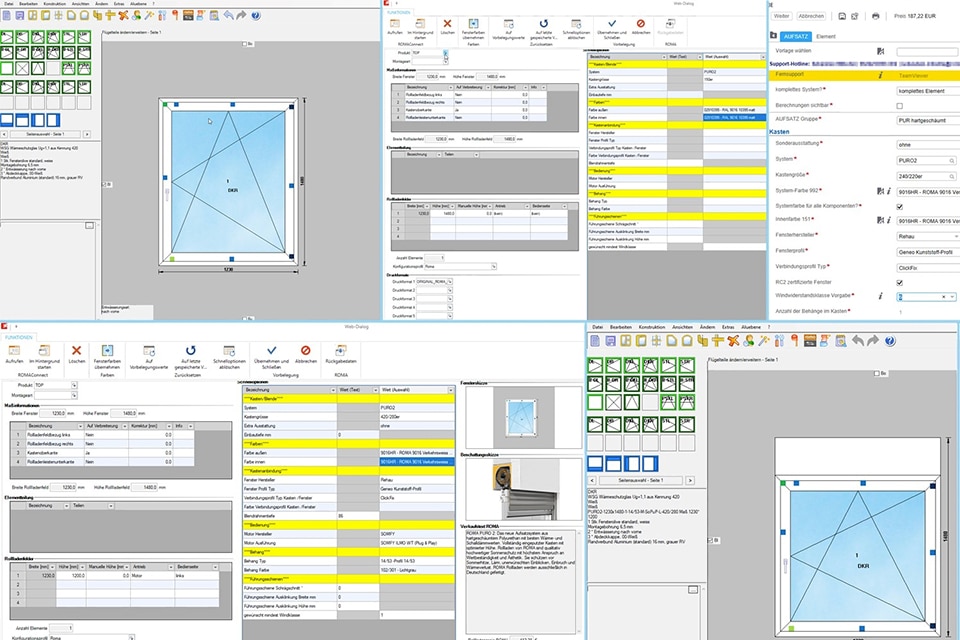

An impressive example of process integration and the resulting benefits is the ability to access so-called web configurators or online ordering platforms directly from 3E-LOOK. As a result, when entering orders for windows, various elements, such as fillings, fall protection devices, shutter boxes and shading elements, can easily be co-configured. When setting a position in 3E-LOOK, users open the manufacturer's online configurator and enter the required element into the external system. Texts, images and prices are then transferred from the element into 3E-LOOK. These can be displayed on quotations, order confirmations, reports and documents. Ordering the configured elements can also be done directly from 3E-LOOK.

The entire process allows for more efficient order processing, both at the customer and at the manufacturer. It is further proof that when all partners involved cooperate with each other, they all also benefit from digitalization. Today the configurators of sun protection specialists Alukon, Beck & Heun, Growe/Roltex, Hella, Roma, Stemeseder and Warema, as well as those of Adeco, Obuk and Rodenberg for infills and of Gutmann for fall protection are available in 3E-LOOK. Soon the online ordering platforms of Duotherm and Schlotterer will also be available for consultation.

Future-proof thanks to fully digital solutions

The digital transformation offers numerous advantages as more and more components can be linked together. One example is the integration of web configurators for accessories, which significantly simplify data entry and save valuable time. Integrated materials management improves the procurement process by partially automating processes with suppliers. The digital exchange of documents ensures complete transparency and thus reduces the workload for the purchasing department. As a result, material resources can be optimally planned and managed and lead times and inventories are reduced.

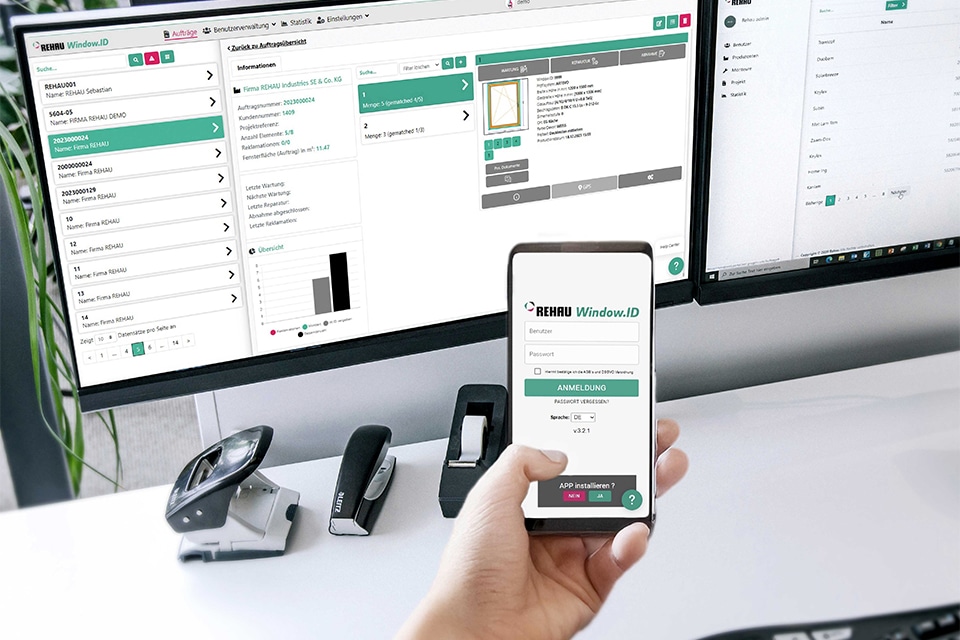

Mobile solutions enable the complete implementation of processes on the construction site or at the customer site. Field workers can access information and collect data on site without having to coordinate with the office - and enter this data into the system without paperwork or wasted time. Thus, information is sent to the ERP system quickly and, above all, reliably. A sophisticated status management system ensures that up-to-date information is available throughout the system.

Setting the course for the future with 3E-LOOK

Fully digital, automated processes and links guarantee smooth data flow and reduce manual efforts. The technologically leading software for window construction 3E-LOOK not only results in greater efficiency in window production, but also lays the foundation for long-term sustainable success and competitiveness.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met 3E Datentechnik GmbH.

Contact opnemen

Contact opnemen