Greater efficiency and fewer workers required are the keys to success.

Practical examples – reference cases – from the industry

For Kruba in Baarn, October is a month in which two important deliveries are made to the market. Cees and Niels van Essen are therefore very satisfied. They are happy to talk about the automation system for tilt and turn windows. They organized and delivered this system for two manufacturers, namely WN Kozijnen in Dinxperlo and Kozijnbouw in Enschede. “Both clients are now seeing demonstrable efficiency gains with fewer workers. And both parties can now continue to serve their customers based on market demand!”

Delivery of automatic batter assembly center

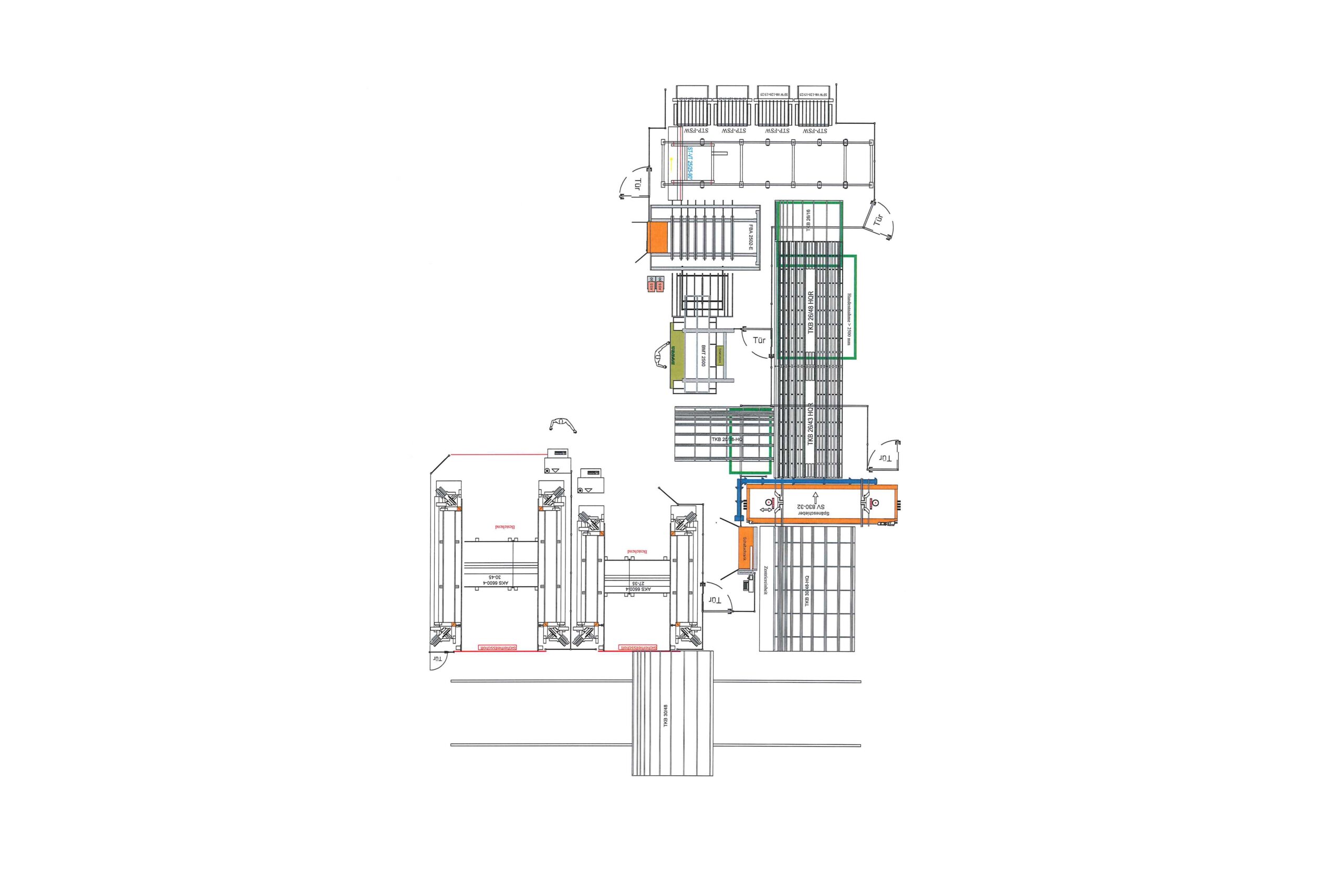

“Earlier this year, we delivered two Urban welding machines to WN Kozijnen in Dinxperlo (see the article in the previous Profiel, ed.), but now in October, the follow-up was on the agenda,” says Niels. “This involves the delivery of an automatic fitting assembly center from Urban, the FBA 2500/2 to be precise. The big win for our customer? Well... the automated fitting assembly saves one FTE. And... production also takes place in less time. So, lots of profit and efficiency.”

Cees: “After scanning, the data for the fittings is displayed graphically on the screen. The electronic length stop is then positioned. Once all the fittings have been entered, they are automatically screwed into place. Once this operation is complete, the tilt-and-turn window is automatically transported to the destacking system, where it is placed vertically on the trolleys – the buffer system.

Niels briefly outlines the most important specifications: “It is fitting and profile independent, there are two high-speed screw units, it has a short cycle time, casement windows can also be screwed automatically, there is an automatic scissor/closing mechanism, and the machine is also suitable for multiple and different screw lengths.”

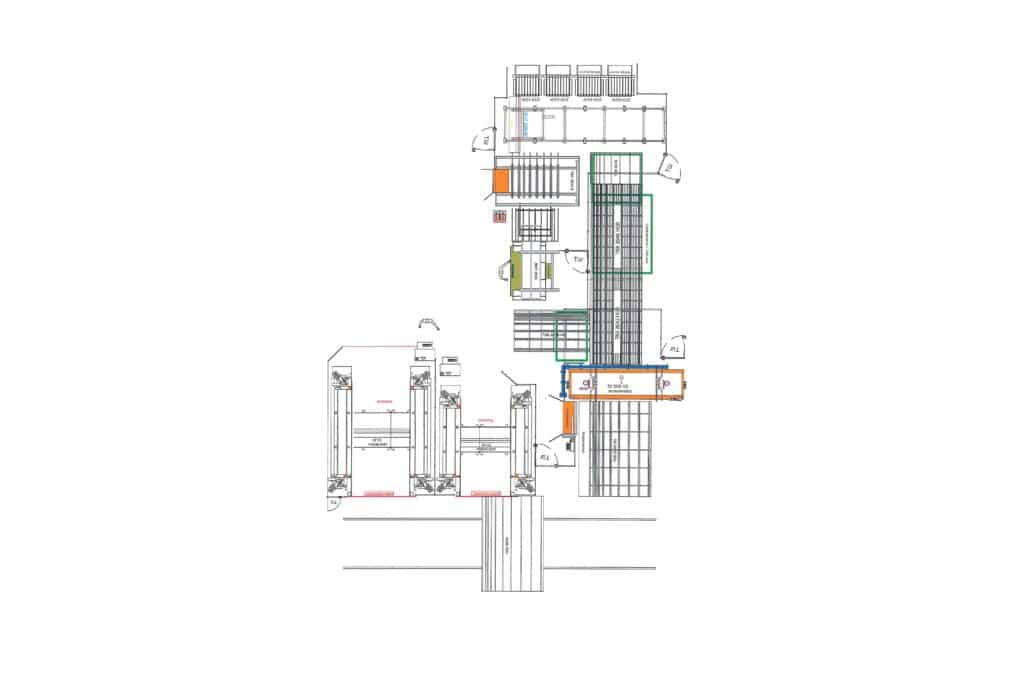

Delivery of Urban Four-Point Welding Machines

Kruba supplied two four-point welding machines with an automatic transport system to a dual CNC corner machining center for the Kozijnbouw company in Enschede. “These machines are also from Urban,” explains Niels. “The turn-tilt wings turn left in production: the fittings are screwed in place by the automatic screw system. The frames go straight to the buffer system, where they are placed in the buffer trolleys. What is the benefit here? Here too, production can be speeded up and approximately two FTEs are gained. Whereas our customer previously needed four people to do this work before the automation upgrade, after delivery they can achieve the same production with just two people.”

According to Cees and Niels, Kozijnbouw in Enschede now produces around 800 window frames per week. “They want to grow to a production of around 1,000 window frames per week in the short term. And they are going to succeed in doing so. This smart automation is therefore delivering them a high return.”

The two October deliveries prove exactly what Kruba stands for. But demand from the market remains. In fact, demand is actually increasing, particularly in the renovation segment. In order to continue to meet this demand, you really have to make the move to automation. Doing nothing is no longer an option. Fortunately, technological advances offer the solution.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Kruba.

Contact opnemen

Contact opnemen