Global solution compatible with approximately 20 window construction software systems

Unique identifier anticipates introduction of digital product passport

As a developer/producer of polymer-based solutions for the construction, automotive and industrial sectors, REHAU regularly brings out innovations to give more substance to the applied circular approach. One of these is the Window.ID, an invention that not only allows each installed window to be closely tracked throughout its lifecycle, but also seamlessly links up with the digital product passport (DPP), which the EU will make mandatory from 2027. Koen Schepens, sales manager Window Solutions Benelux on behalf of REHAU, explains more.

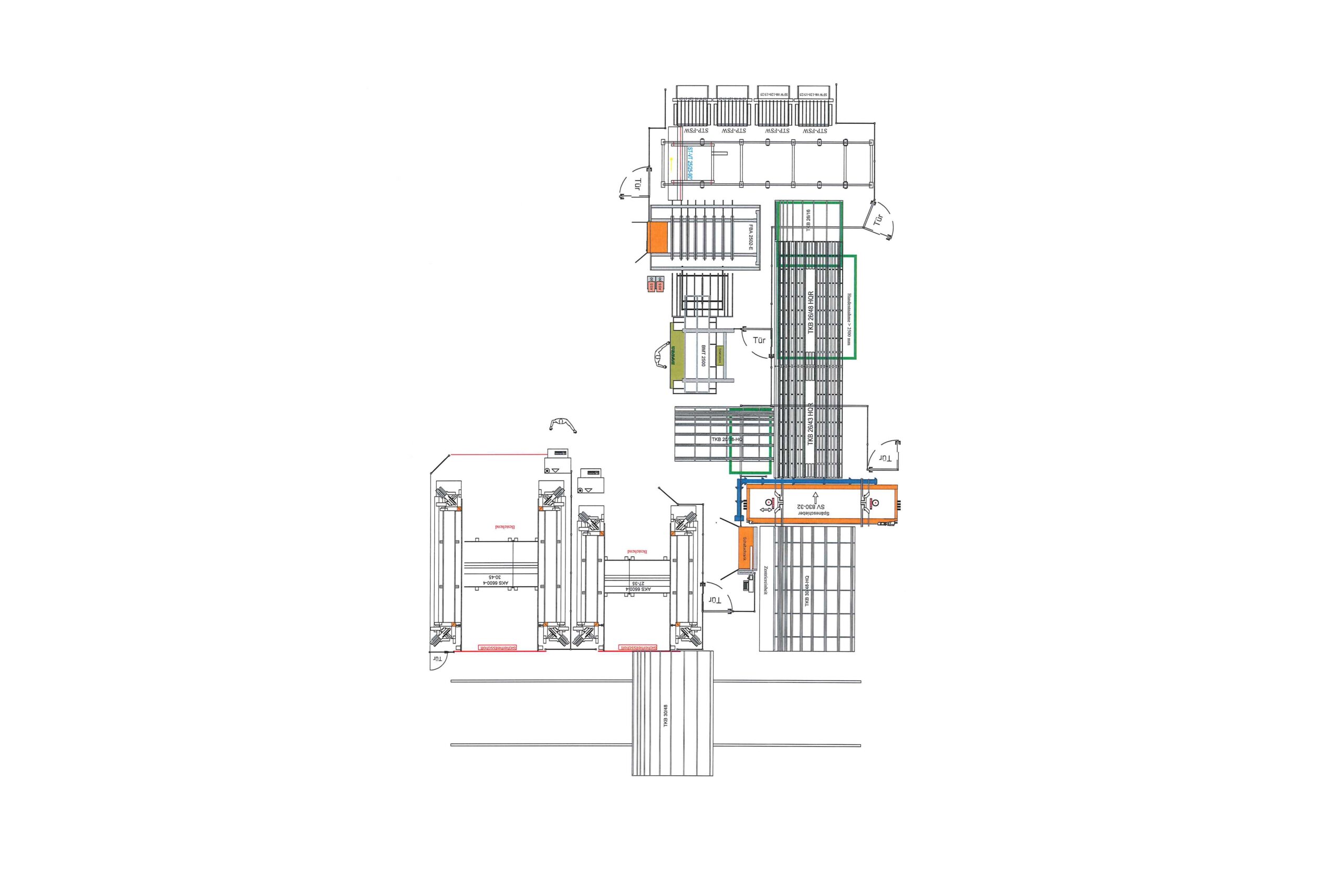

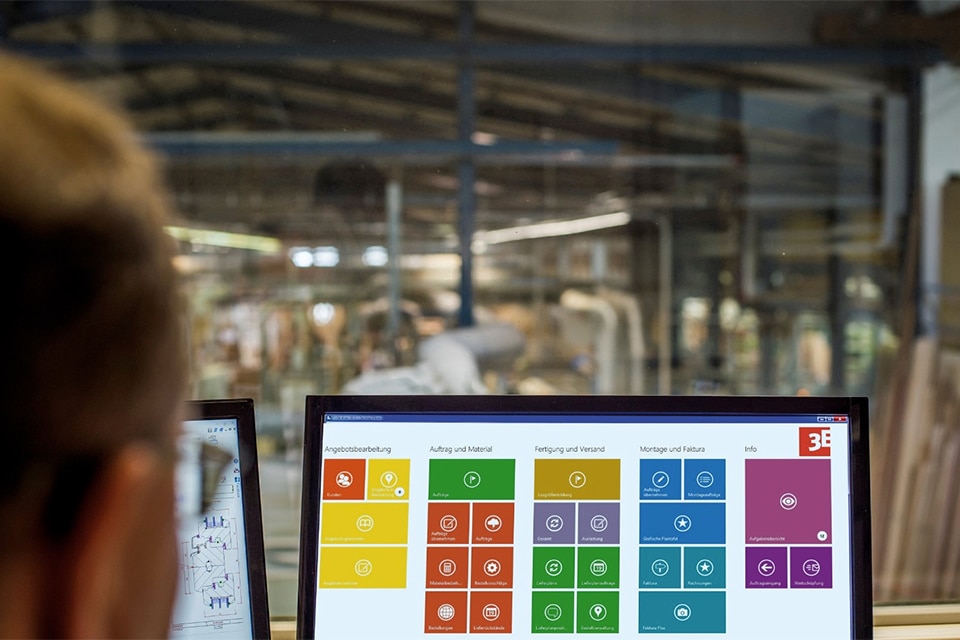

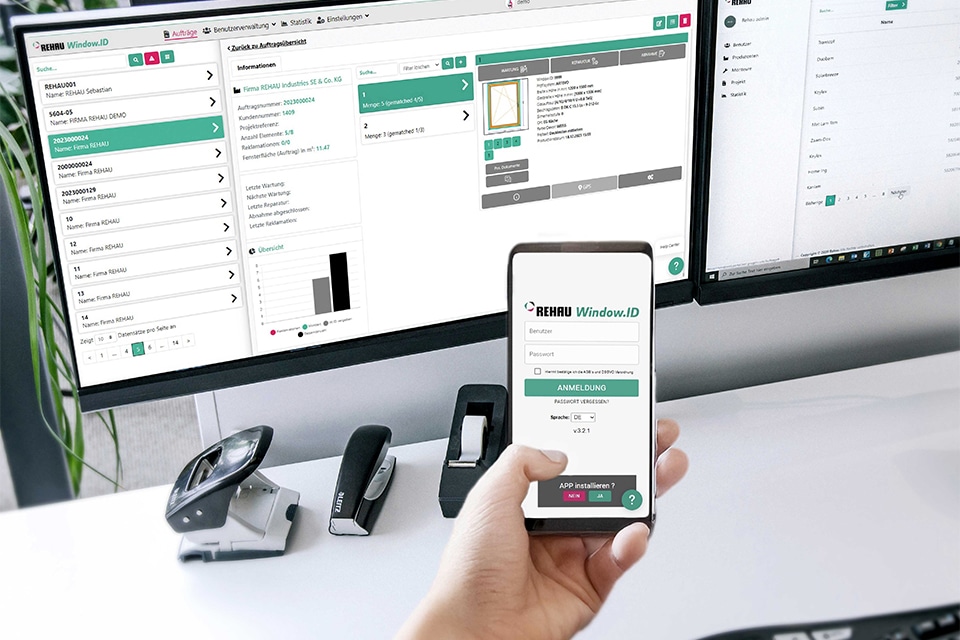

As previously reported in Profile 04-2024, the REHAU Window.ID provides window elements with a unique identification tag with QR code and RFID technology. Regardless of whether they are made of plastic, wood or aluminum. “The REHAU Window.ID ensures that everything around the installation of objects becomes transparent,” Schepens says. “Each window element acquires a unique identity, so to speak, and is always and everywhere recognizable in the chain. At the same time, the manufacturer, processor or end user has direct access to all information about the element in question during its entire lifespan using the digital pass. This includes, for example, relevant data, applicable certificates and operating instructions. Currently, REHAU Window.ID is already compatible with about twenty window construction software systems and available in eighteen languages. The solution works independently of the material or profile system used and can be used immediately, without interrupting operations. After all, you don't have to set up any system data, these are provided by the leading system.”

Digital identity for windows

Proactively developed for partners and customers, the REHAU Window.ID anticipates the arrival of the mandatory digital product passport (DPP). This will be made mandatory by the European Commission with effect from 2027 with a view to greater sustainability. The DPP offers more transparency in terms of sustainability and provides everyone with a better view of the product and its origin.

“The characteristics of a product - sustainable or not - are not universally known or understood by everyone,” Schepens explains. “The passport solves these problems and gives consumers, companies and policymakers answers to several questions. Where does the product come from? What is its composition? How can it be reused? What sustainability labels does it have? By scanning the unique identifier on products, all of this becomes clear with one simple action. Furthermore, the added transparency offers the advantage of making repair, reuse and recycling of products easier.”

Practical experiences

By now, a large number of REHAU customers are using Window.ID. To their complete satisfaction, as the reactions show. In many cases, the smooth and fast integration into the production environment is praised. As does the ability to link the system directly with other software within the company walls. This functionality saves a lot of time, increases data quality and significantly improves cooperation with partners.

“You can create your own website for each individual product, where customers can use the QR code to find information on, for example, CE markings, maintenance instructions, documents or contact information,” Schepens explains. “But your own employees also benefit considerably from this invention. Even on the construction site. I hear more and more that people in the field are using the digital documentation app to get the job done. Whether it's photos, assembly steps or accessories: everything is immediately recorded and included in the digital inspection report. This saves a lot of paper, reduces the chance of misunderstandings and makes it easier to plan maintenance. Count your winnings.”

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Rehau.

Contact opnemen

Contact opnemen