A successful 'production marriage' between machine, software and hardware

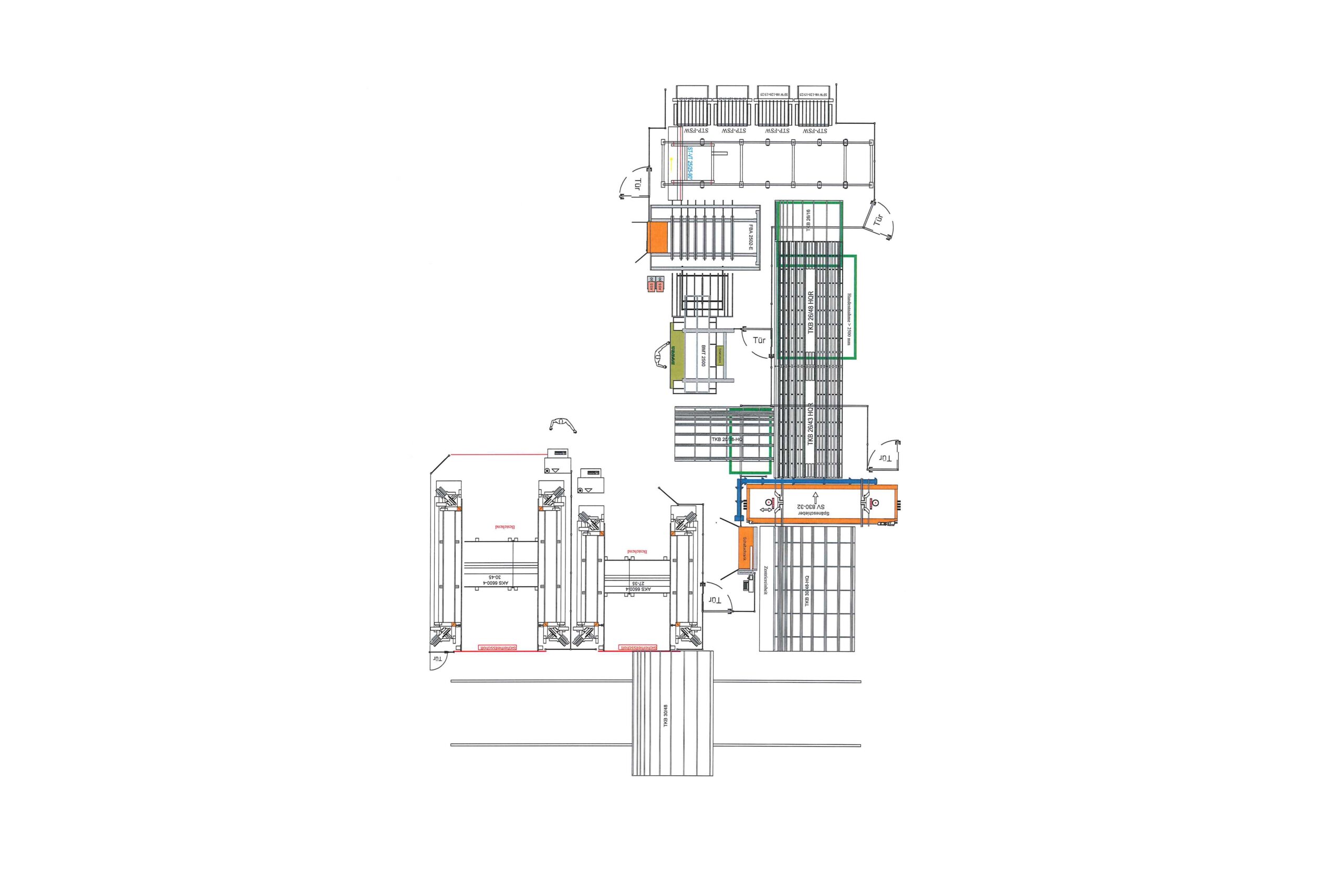

How can you streamline a production process and optimize it further and further? Rudolph den Boer, the man responsible for process control and automation at Van de Vin Ramen en Kozijnen in Heeze, deals with this every day. Recently, under his supervision, RFID and MES technology entered the company.

RFID is short for Radio Frequency Identification and is a technology that uses radio waves to passively identify a tagged object. This is used in various commercial and industrial applications: from tracking objects in a supply chain to easily retrieving specifications about a particular object. By applying RFID tags instead of the traditional papers that travel with a frame through production, there is a huge efficiency gain at Van de Vin.

'Single source of truth'

To understand the advantage of frame data on an RFID tag, it is good to first know the disadvantages of paper. Den Boer explains that the papers traditionally associated with the manufacturing process are often large A0 drawings, with frame views and details. Thus whole packs of paper go through each year, which are clumsy to use and involve a lot of looking and searching. In addition, multiple drawings may be in circulation. Who says a production worker has the latest version on paper with him? You only find that out when things go wrong. In short: a lot of paper is used, working with paper administration is labor intensive and there is a chance of failure, when there are changes.

An RFID chip can bring up all the information in the ERP system. The RFID chip contains a unique code that is linked to information about the frame in question. The RFID tag is applied to the window frame and travels with it throughout production. At each intermediate station, the RFID tag can be briefly scanned, the data relevant to the production worker is displayed, and via the ERP system feedback is given to the office where the frame is located in the factory. And all this is paperless. The RFID tag is a so-called single source of truth, because changes sent from the ERP system to the tag are always displayed in the latest version on the screen of the person scanning the RFID tag. The beauty is that the RFID tag stays in the frame and goes with the construction. In future service or replacement work, the RFID tag need only be scanned to recall all the specifications of the frame.

Frame industry will also increasingly robotize

For the RFID part of the automation, Van de Vin engaged the English company RFIDdirect. With 25 years of experience in smart RFID solutions, this company develops solutions for inventory tracking and project management, including in the wood processing industry. At Van de Vin, the UHF-RFID technology is applied; the tags operate at Ultra High Frequency (UHF) (865 MHz to 928 MHz). From its base in Kleve, Germany, RFIDdirect closely follows developments in the timber sector. Business Development Manager Auto ID Mohssine Ouchen of RFIDdirect says, "The market is going to robotize. With that comes a huge data flow. Van de Vin and many of their colleagues are increasingly discovering the benefits of RFID."

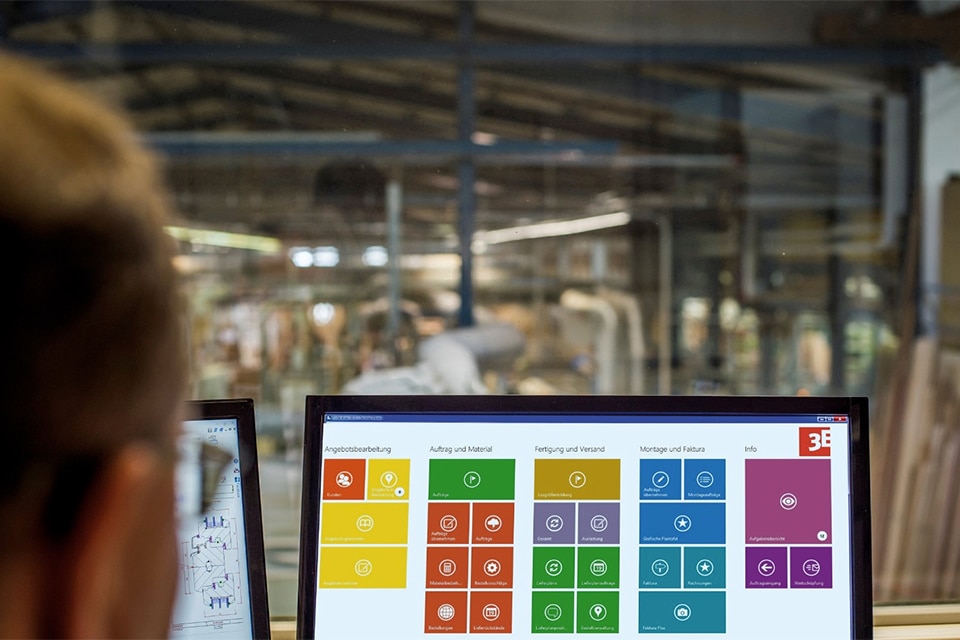

Without the right software, nothing happens

Technology such as RFID is of no value if the hardware is not linked to the right software. Van de Vin invested in software platform MES (Manufacturing Execution System) from Matrix Software of Nijmegen. Each workplace in production now receives via a tablet exactly the information needed at that moment for that specific production station. The RFID tag is inserted as a plastic dowel after the initial processing of the wood and activated with the first data. Den Boer says the system is "live. That means that when you add a change in work preparation, change frame dimensions or change hardware, it is immediately reflected in the system.

Changes made during the production process are also immediately "live. From that moment on, everyone has the latest version of the production details. Den Boer indicates that there is a link in the production chain: as soon as the uploaded changes are processed, any subsequent stages are also immediately adjusted. So there is no need for specific interaction between work preparation and production when it comes to feedback. With the Matrix MES software comes another big advantage: the data generated and stored can be used for analysis. You get totally new insights because everything is digitally documented down to the last detail. If we are talking about further optimization (not only in the plant, but also in work preparation and even in calculations), then the stored data is proverbial gold.