Digitizing a firm is about improvement processes

Digitalization helps to improve and shorten processes and production processes transparently. Klaes has innovative IT solutions for every level within a company, which efficiently support the production of windows, doors and conservatories. Each piece of work goes through a large number of different stages in a production process. Transparent communication and information are important factors here. To work this way, all business processes must be optimally connected. Professional software is a must - a software, which completely manages organization and sales, planning and production from quotation to invoice.

At the office

With Klaes' solutions, complex situations suddenly become child's play. From input, Klaes provides all the necessary elements to lay the foundation for a successful production process. Positions can be created in no time at all - wood, wood-aluminum and plastic are all entered in the same way, but in the background, depending on the material, everything is defined down to the smallest detail.

Quotations, orders, delivery notes, invoices - everything is displayed extremely clearly per production or project. The calculation of prices as well as the processing of customer discounts - everything happens automatically. Based on capacity, the delivery date is displayed or the feasibility of the customer's desired delivery date is checked.

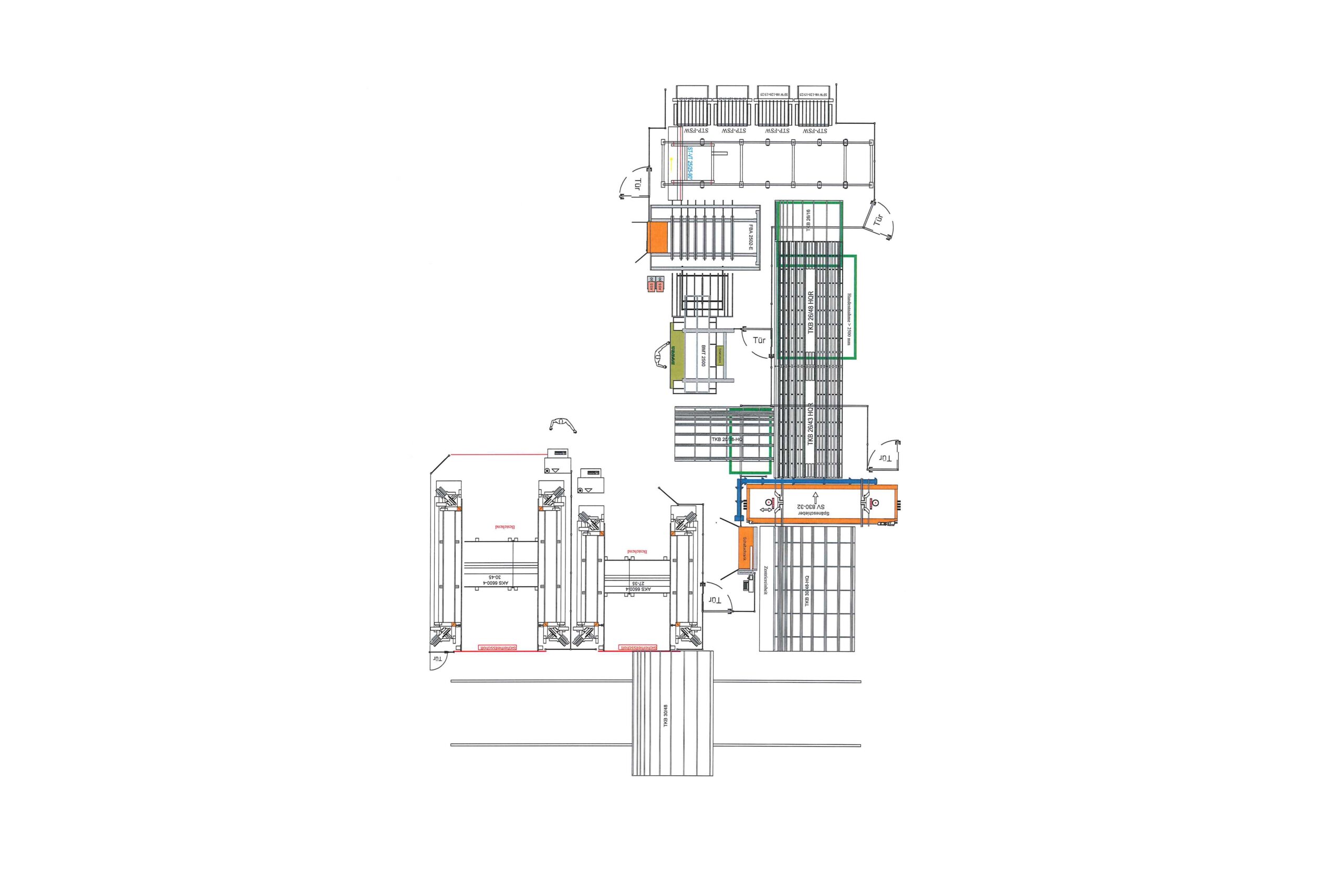

Klaes Kapazitätenplanung' - the hub for optimal organization of business processes.data on the components.

After order confirmation, all desired data can be optionally taken over in one or several production orders or positions from several offers can be combined in one order. Thanks to this flexible way of working, the production process can be perfectly matched to the required sequence for the delivery of the finished products, for example, if it has been specified in advance that the doors should only be delivered after the windows.

The modules "Klaes Bestellwesen" or "Klaes Materialwirtschaft" ensure that the elements for each specific phase in the production process are present in time. The orders can be sent to the supplier in the classic way by mail or with openTRANS bi-directionally in the background. Specific information for the production of the pieces can also reach the workplace in two ways - on paper or digitally with "Klaes e-control" for the control of the machines and "Klaes e-prod" for the organization of production and delivery.

Concentrated and fast work when installing the hardware thanks to

accurate component data.

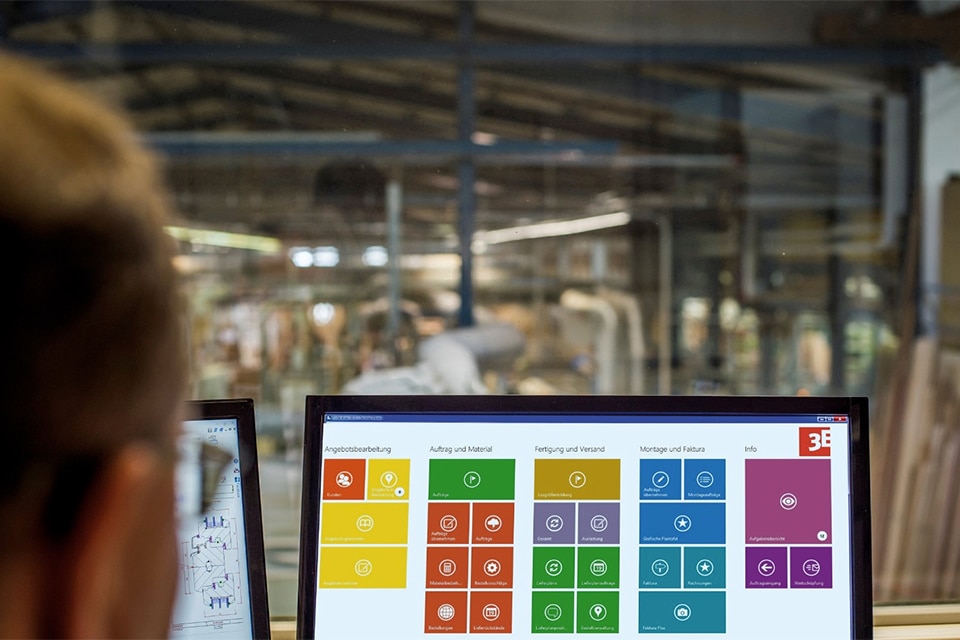

In the workplace

With the "Klaes e-control" module, all data for the machines are prepared perfectly. Whether cutting, drilling or milling - all machining operations are carried out fully automatically. Machining centers or welding machines perform several operations in one step, and here too Klaes ensures the safe and reliable control of the machine. 'Klaes e-prod' adapts optimally to the production process, as this module can communicate very flexibly from the intranet with existing systems or organize the entire process.

Digital transparency at the click of a mouse: live information from the shop floor on the status of the production process, as well as the display of many other important data.

Service is also important

Digitization creates many opportunities. Successful implementation and future control of business processes require not only the appropriate solutions but also the active support of the software partner. For years, Klaes has attached great importance to comprehensive support and service for its customers. Important aspects are the wide availability of 'hotline employees, individual training of customers, perfectly coordinated integration of data and continuous cooperation with suppliers of machines and materials.