Digital drawing package prevents implementation disappointments

Goedhart Bakery Kitchen specializes in the production of pre-packaged food concepts and serves customers in a variety of sectors, including retail, foodservice and aviation. They do this from production locations in Leeuwarden, Alphen aan den Rijn and Losser. In the Friesian capital, they recently moved into an entirely new building. Commissioned by main contractor Friso Bouwgroep, Slump-Fictorie was responsible for the engineering, production and assembly of the various curtain walls in the building. Most of it straightforward, but with a twist at the main entrance and at the corners.

Direct coupling

Slump-Fictorie engineered the curtain walls entirely in HiCAD. "We have been working with the software for over three years now and we like it very much," says director Harmen Slump. "It basically requires a little more work to set up a drawing than we were used to, but it brings so many more advantages. In particular, the direct link with Logikal from Orgadata saves us a lot of time. It also prevents unnecessary errors between the CAD drawing and the Logikal files that form the input for purchasing and work preparation and production drawings, among other things. A change in the drawing in HiCAD is automatically adopted in Logikal and vice versa. It is also very convenient that drawings can simply be loaded into BIM. That is what happened in this project. Our HiCAD drawings are loaded into the contractor's 3D BIM model, so that our customer - the contractor - can check whether everything fits."

Clashes

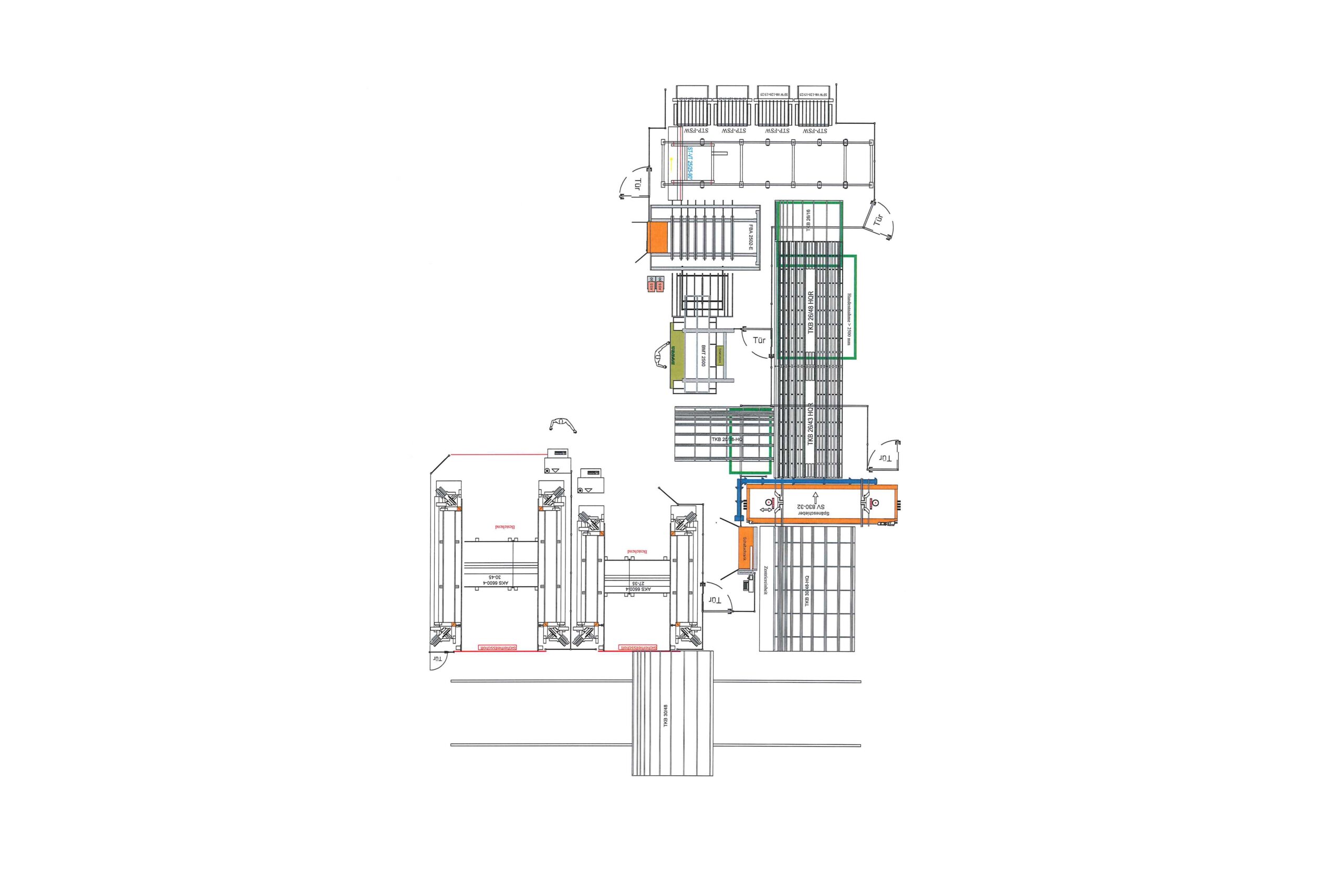

The curtain walls of Goedhart Bakery Kitchen's new building are constructed in Kawneer's AA 100 Q system and equipped with solar control glazing and enamel black Colorbel panels. "Biggest challenge here was getting the curtain walls at the corners to fit together properly," Slump reflects. "And that in combination with the sloping line of the lintel that moves up with the stairs at the main entrance. To make everything fit together perfectly, the steel structure had to be adjusted in a number of positions. This could hardly be seen beforehand, but only surfaced when our HiCAD drawings were loaded into the 3D BIM model. At various positions, the footplates of the steel construction collided with our aluminum curtain wall. So those were adjusted in advance to avoid disappointments during execution."

Another concern was the blinds. "The awning slats were installed by third parties, but we had to prepare the studs in advance in our curtain wall profiles," Slump explains. "In HiCAD, we were able to position that very easily and indicate it on the drawing, so that it was completely clear to our production and the awning supplier. The studs were inserted into the nose of the profile and after the curtain wall was assembled, the slats were fitted to it by a third party. Everything fitted perfectly. And that is what characterizes this project. Thanks to HiCAD, I am convinced of that."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met ISD Benelux.

Contact opnemen

Contact opnemen