3D software platform automates production processes in profile machining

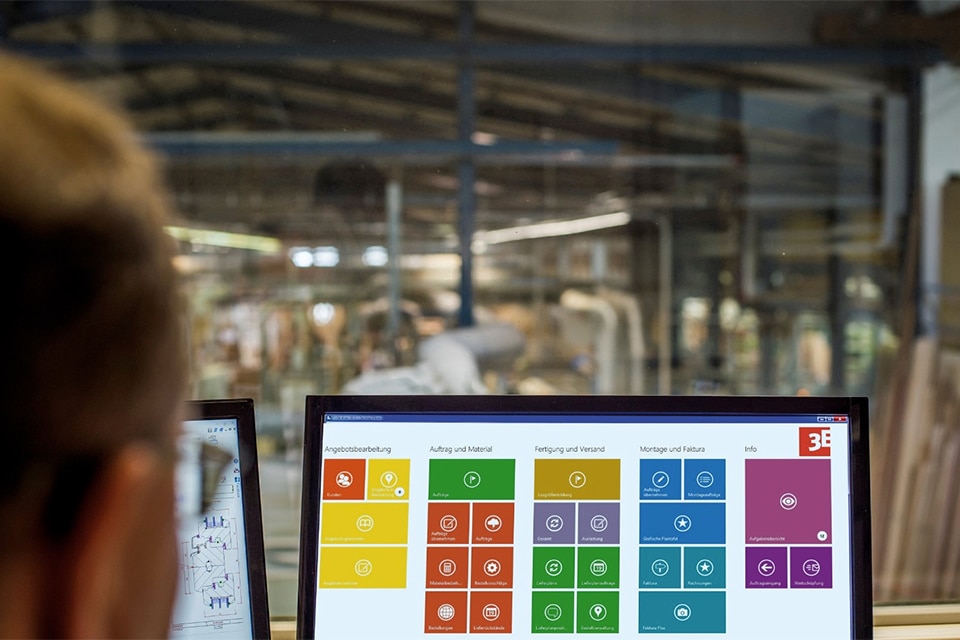

The days when machines were programmed on the shop floor by production managers and operators are gradually becoming a thing of the past. More and more companies are opting for extensive automation and digitization of their production processes. The Uni-Link software platform allows manufacturers to easily control their CNC machining centers from the office, as if printing a document from their PC. This provides increased efficiency and significant gains in machine time. Moreover, the specialists implement and configure this software platform in two working days.

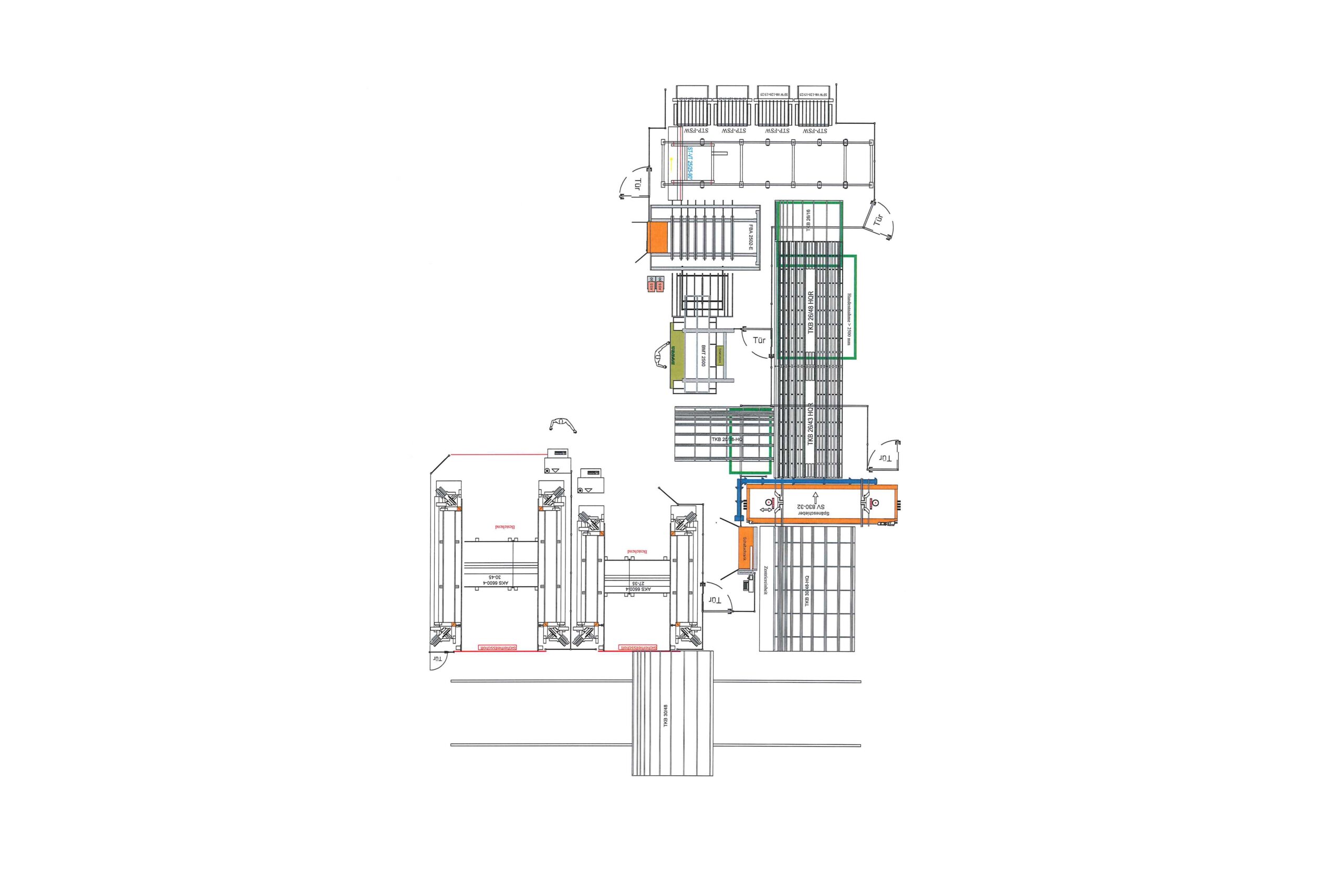

The Uni_Link software platform enables window manufacturers, door manufacturers and facade builders, as well as other manufacturing companies, to fully automate the machining of profiles in aluminum, steel and plastic on CNC machines. The software house thus offers a universal and user-friendly CAM software that is compatible with all makes and types of profile machining centers. Moreover, users can work with all types of profiles and software. ERP program, calculation software or 3D solid drawing package, Uni_Link always ensures that the machines are sent the correct production data.

"We want to simplify complex processes and are convinced that it is a waste of time if the operator has to program everything on the machine and it just stands still. A machine is like a printer and it has to run continuously. If the work preparation, programming and checking is done in advance in the office, the workload for the operators is minimized. After all, they only have to "handle" the profiles and scan in the bar code. This way, everything goes much faster, the risk of errors is significantly reduced and machines no longer stand still," explains Jan Vandyck, manager of Uni-Link.

"In addition to machine control, this software platform includes numerous other functionalities that save firms time and money. For example, there is a powerful optimization module that ensures that one has as few residual parts as possible. If there are still residual parts, they can be included in the next optimization. If there are often damaged profiles with dents or scratches, then these damages can be indicated in the bar lengths and then optimized and cut away neatly."

An appropriate solution for every application

Uni_Link is a comprehensive "toolbox" for managing all possible automation tasks towards the machinery, compatible with different machine brands, production software solutions and even companies. As a partner in automation, Uni-Link thinks with customers to always offer the right solution and can also grow the software with the firm. More than 1,000 companies worldwide have put their trust in Uni_Link and, according to the software house, enjoy the simple but powerful functionality every day to make the automation of their production an uncomplicated task.

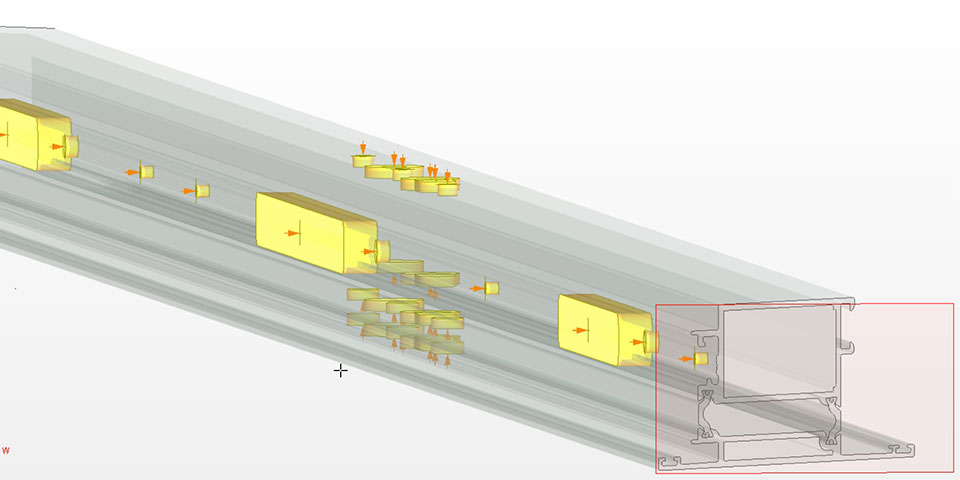

"For those who don't yet have a CNC-controlled machine on the shop floor, Uni_Link can already generate nice drawings (DXF) of all profile parts, with all machining operations and their matting included. In this way, it is very easy to perform the necessary operations even manually. If you draw the products in 3D Solid software, we offer a solution that converts the 'STEP' drawings, interprets them and converts them to optimized production lists for the CNC machines," concludes Jan Vandyck.

"If manufacturers do not have calculation or drawing software, but often produce the same products with varying dimensions, they can use the ProductBuilder. This allows all possible constructions with profiles based on simple scripts to be created as parametric models. These can then be reused endlessly to control machines, create DXF drawings and reports, print barcodes and, if necessary, provide feedback to the ERP system."