Screen cloth remnants get second life as totebag

Renson boosts sustainable and social commitment with new gadget

As an efficient prevention of indoor overheating, cloth sunshades are a sustainable solution for a healthy indoor climate. In the production of the screens Renson is committed to using renewable energy, long product life and limiting residual waste. Inevitably, screen fabric remnants are created. Some of these scraps are now being given a second life. They form the new raw material for an exclusive Renson totebag, manufactured by tailors van 't Veer in Menen.

650 kg of waste recovered

In the production of screens, cloths are cut to size. This creates cloth waste. The new totebags recover about 260 grams of screen cloth waste per bag. In 2024, the first 2,500 of these special totebags will be produced. This represents around 650 kilograms of fabric waste that will be given a new function in the first phase of this project. Supply chain manager Leen Vermeir of Renson: "It is not the first time that we use waste from our production in a circular way, nor that we link a social commitment to it. For Kom Op Tegen Kanker we already made similar toilet bags."

The new Renson gadget is already perfectly in line with the company values. Sustainable, innovative design runs like a thread through the range of ventilation, sun protection e n outdoor living. And now also through totebags, which are functional, aesthetic and maintenance-friendly.

Partnership with custom company

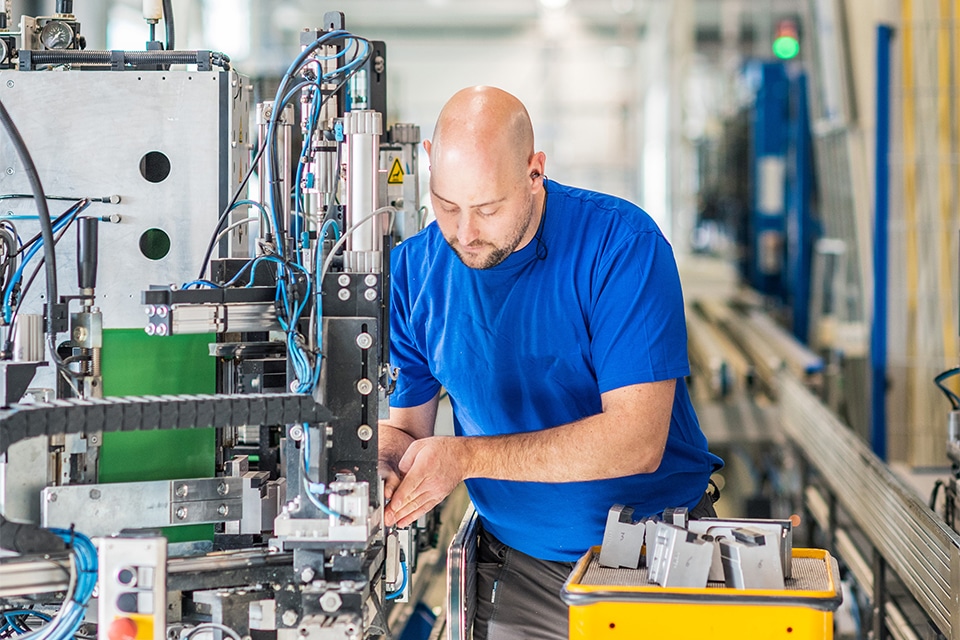

For the manufacture of the totebags, Renson calls on the customization company 't Veer from Menen. The 'green' bags take careful shape in the production department. "Our employees already find it a fun project to work on," says production manager Yoeri Vermeersch. "Sustainability is also high on our agenda. So being allowed to make products like this and thus contribute to a more environmentally conscious society is something we applaud."