Risks when using roller shutter parts from different manufacturers

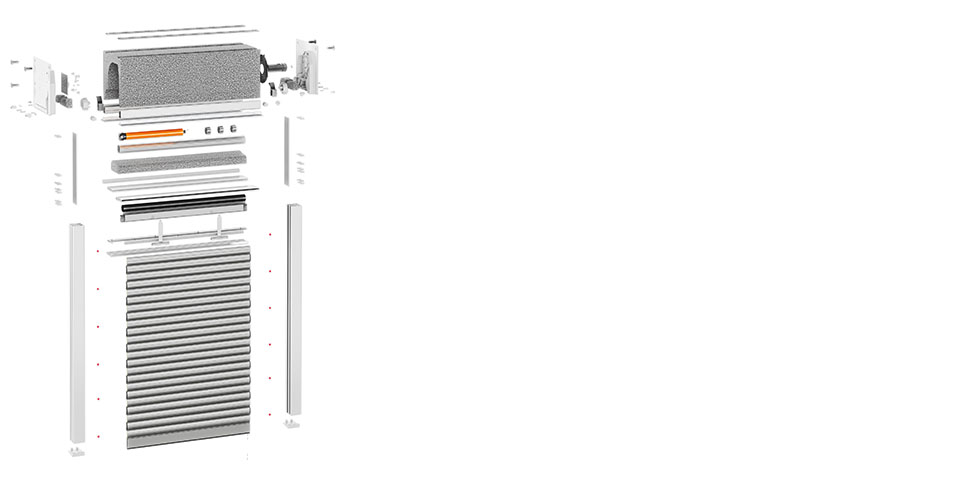

A whole range of factors influence the correct operation of exterior roller shutters and thus the level of thermal insulation to burglar resistance. Correct installation is just one of those factors. Another important element that ensures correct operation is the production method. The main issue here is whether the production process follows the supplier's guidelines.

Know-how

In addition to parts for exterior roller shutters and roller gates, Aluprof - like other suppliers - provides a complete package of technical information, expert knowledge and practical solutions to its customers. Nevertheless, some often use parts from different suppliers. They do this out of habit or for economic reasons. However, practice shows that this is only a false economy, as such an approach can lead to inconsistency, errors and increased technical interventions and/or repairs in the future.

What is the risk of mixed use of shutter components?

A use of shutter components coming from different manufacturers can have serious consequences. Seemingly identical elements can differ considerably in both quality and functionality. It is enough to change the type of material from which a particular detail is made (e.g., an attachment, shaft plug or sealing cap) to have a huge impact on the entire product. For example, if the attachments are too brittle, they will crack. If the end caps were manufactured in plastic that absorbs moisture from the environment, problems with swelling and peeling shutter blades will occur. Mounting differences are also of great significance. Even minor deviations or roundings can hinder or prevent the assembly of parts - which have not previously been tested for their applicability and compatibility. In practice, it often happens that a properly functioning final product depends on dimensions down to even the tenth decimal place. In this way, for example, connected parts may have too much play, which can ultimately lead to faster wear of individual parts. It is even possible that connection is not possible at all, because the space provided is too small.

Disruption of production

It is also worth bearing in mind that the production of finished products that do not correspond to the supplier's recommendations has a major impact on the production process. For example, different sawing dimensions may have to be used for individual components than those prescribed by the supplier of the complete system. Some manufacturers do not take this into account, with all its consequences. In addition to the technical aspects, aesthetic considerations also play an important role. If individual components are combined with each other and are not perfectly compatible, this unfortunately has consequences not only in terms of functionality, but also in terms of aesthetics. In addition to the aforementioned factors, it should not be forgotten that by using parts from other suppliers, a manufacturer usually cannot claim a subsequent warranty.

Most common mistakes and their consequences

The use of parts from different suppliers can negatively affect the performance of the final product. Here are the most common errors and their consequences:

1. Guides and seals in guides - differing dimensions of the space in which the shutter blade is located translate to its operation. If they are too narrow, the shutter blade experiences resistance; if they are too wide, the shutter blade may undulate.

2. Suspension springs - if chosen incorrectly, they can damage the paint of the shutter blade; improperly fitting springs cause improper buckling of the profiles.

3. Bottom bar or end bar- if it is too small it leads to waves of the shutter blade; too thick an end bar blocks the shutter blade in the guide.

4. Bearings and sliders - if these are chosen incorrectly, the shutter will fall out of the guides.

5. Slats of roller shutters, roller gates or grilles - slats of varying thickness or shape will not function correctly in the guides and cause disturbance of properties (e.g. wind resistance).

6. Axes - each axis has individual bending parameters and its own compatibility with accessories.

7. Mosquito window - improperly chosen seals, hinges or mesh cause the loosening or tearing of the mosquito window, giving insects free rein.

Mixed use of parts and inspection certificates

Unfortunately, few people realize that a random change of parts during production results in the creation of a completely new end product. Consequently, this end product has completely different properties from the products that were made based on the technology of the system supplier. When putting such products into circulation, their properties must be confirmed at their own expense by appropriate examinations at a research institute. The test certificates from Aluprof are not binding in this case. To save time and money, it is therefore worth following our technology from A to Z.