KRUBA from Baarn offers solutions for the frame manufacturer

Whether it is machining, welding, angle machining or polishing, specialist KRUBA from Baarn has a suitable solution for everything. At KRUBA, the customer not only receives the machine, but the excellent support the company has to offer is also part of the delivery. We find ourselves at the KRUBA office for an interview with director and owner Cees van Essen.

Machining machines for plastic, wood and aluminum

"We supply machines for plastic, wood and aluminum from small to very large, both new and used," Van Essen opens the conversation. "Those who opt for a fully automated production line have also come to the right place with us. The software in our machines can be controlled by any ERP package of your choice."

New: seamless welding within two minutes of production time

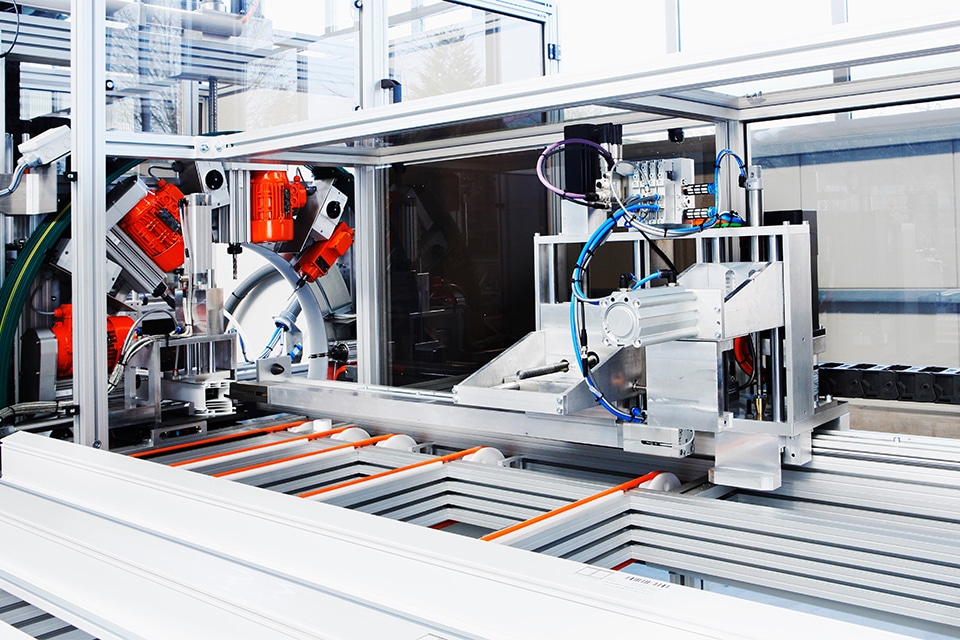

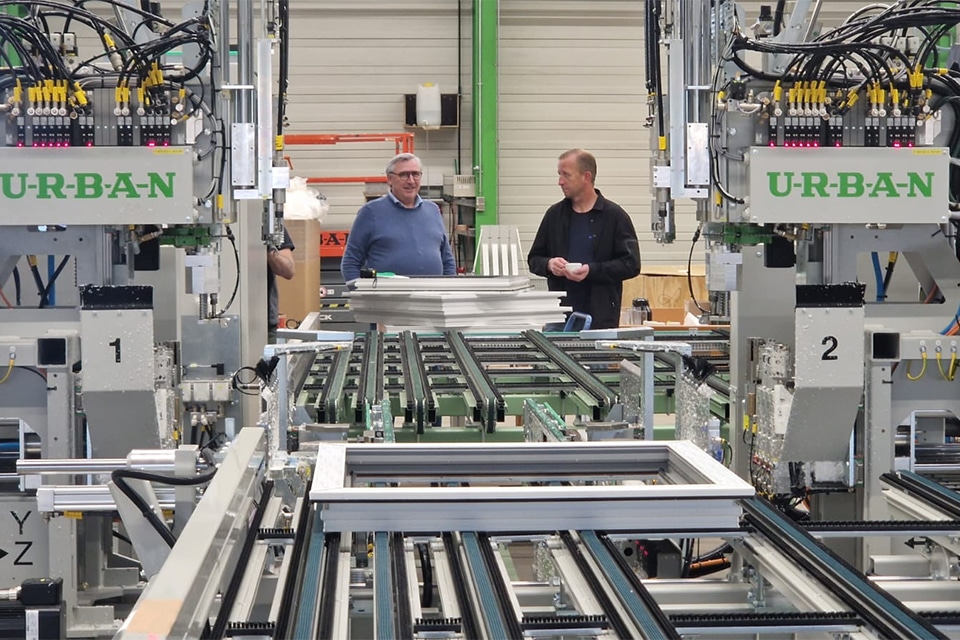

A first is the new welding technology for plastic profiles presented by KRUBA. "The welds can be made with the protective film still on the profile. This prevents damage to the plastic and saves a lot of time. With our new welding technology, a completely invisible weld can easily be made without a white seam coming into view with colored profiles. The technology comes from URBAN, this is a machine that not only processes and welds quickly and efficiently, but also has a long service life. Stable and reliable are the key words here," Van Essen explains.

The URBAN machines can be supplied in various designs and sizes, with a cycle time of 2 minutes. "Also door frames can be welded with it, the sill can be pre-assembled." As a distributor of URBAN machines, KRUBA can supply standard 2, 4, 6 and 8-head welding machines in addition to the URBAN AKS9600/CUT. These are known as very reliable and enjoy great popularity.

URBAN Angle Processing Machines

URBAN's angle milling machines also come in various versions. Van Essen explains, "We supply these in several variants, you can use them to mill points with a stop for two different frame profiles. You can also pre-drill fixing holes for tilt and turn window hinges, in single, double and quadruple versions."

Cutting glazing bars efficiently and quickly

URBAN Welding and Polishing lines can be expanded to include automatic hardware assembly stations for tilt-turn fittings and fully automated buffer systems. Another, nice development from URBAN is the sawing machine for glass slats. "With this machine, you can easily cut traditional mitered glass slats, combined with a manual or automatic length stop. That stop, in turn, can be expanded to allow you to cut four glass laths simultaneously, in two different lengths. That saves time and searching, because everything is done in one sawing operation."

A common problem is that the compartments into which the glass slats should go are too small to fit the glass slats. Van Essen has three solutions for this with KRUBA: "First, we have a milling machine for head milling of the glass battens for the contramal joint. Then there is a KRUBA multi-blade sawing machine for milling grooves, which makes the glazing batten more flexible and third, we have a glazing batten sawing/milling machine in our program in combination with automatic length stop. This one is especially for the 90˚ glass laths with a fully automatic head router for contramal connection." Too much to mention, in other words. Van Essen laughs and says, "Yes, we have almost everything. Even for intermediate posts. For that, KRUBA supplies a 2-fold screw machine, for automatic screwing of T-joints on the intermediate posts."

Machines that pay for themselves

The machines supplied by KRUBA basically pay for themselves, due to their efficiency, speed and accuracy. "It is an end product of optimal quality, which has been achieved through a very efficient and fast work process, and which saves the manufacturer time and failure costs. In addition, it results in satisfied customers," Van Essen outlines. "You can safely speak of a piece of process optimization at our customer, thanks to an appropriate configuration of the right machines. This starts at the front end, of course, by listening carefully to what our customer wants after which we provide sound advice. Our innovative strength is great; we identify the customer's needs and respond to them with our technology. We also listen to the customer's growth plans so that we can recommend a machine park that is also future-proof."

Van Essen hopes to advise many professionals. In conclusion, he says, "As highlights, I would like to recommend the HVL machines for straight-on-slant and HVL connections, the KRUBA CNC Machining Centers, where 4 respectively 8 profiles can be imposed simultaneously, where the HVL connection can be made 1-sided or 2-sided. Indeed, there is increasing demand for 2-sided. With the KRUBA CNC Machining Center, profiles can be milled in advance, for the purpose of seamless welding on a traditional 2- or 4-head Welding Machine."