Custom machining machines for plastic window and door profiles

'Standard' is not in this machine builder's dictionary

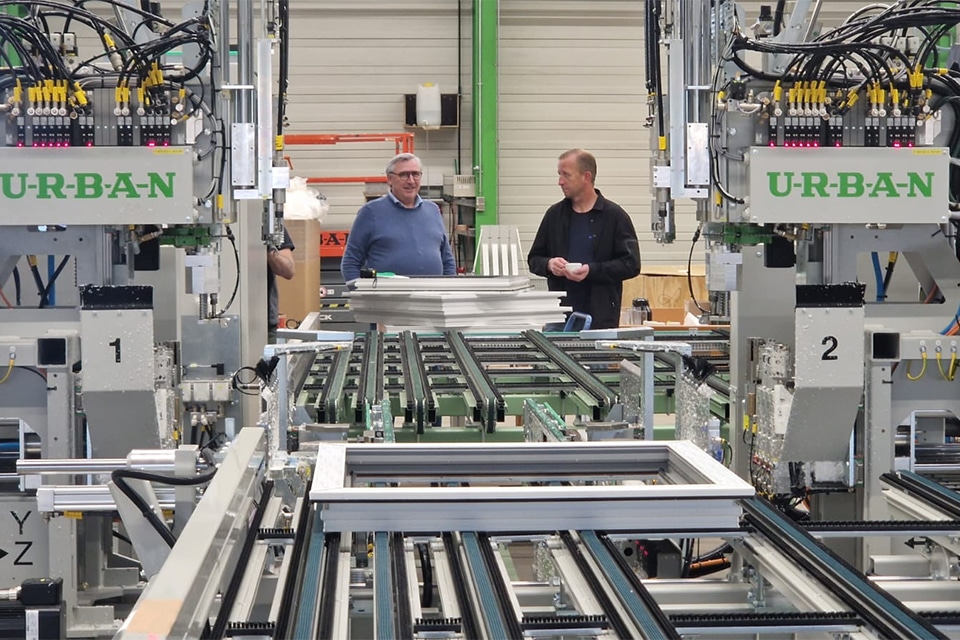

Those wishing to invest in a new machine can choose a system from the catalog, from a distributor's showroom or a customized solution, conceived and produced in close consultation with the machine builder. At Stürtz Maschinenbau GmbH, no two machining centers are alike, because the word "standard" is unknown. Again and again, this German specialist develops and produces a customer-oriented, easy-to-use solution: from stand-alone machines to completely automated production lines.

Every project at Stürtz starts with a white sheet and a meeting at the customer's premises, where needs and requirements are listened to. That information is then converted by an experienced and driven team of employees into a realizable solution within the predetermined budget. This can be a stand-alone unit, but equally a fully automated production line with multiple modules that can perform various operations in one run.

"Modularity is the code word, because after all, there is a difference between the one-man business just starting out in window production and the large company that has been established for years. One thing is clear: as a leading manufacturer of equipment for the production of plastic windows, Stürtz guarantees quality and precision," states technical consultant Marcel Boender.

"This company has more than 75 years of experience in mechanical engineering, employs nearly 360 people worldwide and has 20,000 m² of production facilities. In addition to its headquarters in Neustadt/Wied-Rott, Germany, the company now has its own subsidiaries in Poland, Romania, UK, USA, Canada and China. The comprehensive product portfolio covers various systems required for the production of plastic windows: from profile processing, welding and polishing, fitting of fittings and glass handling to material logistics, including efficient automated solutions with robots. We are also responsible for the expert assembly of the machines and production lines."

'Standard' is not in the Stürtz dictionary. For each project, we work intensively together to develop and realize a custom-made solution.

Modular total solutions

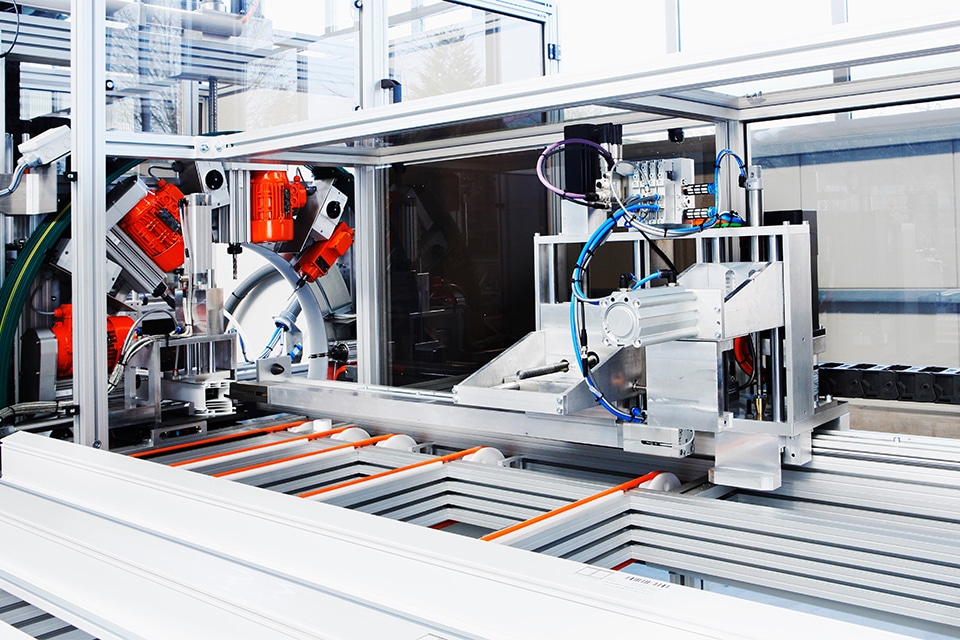

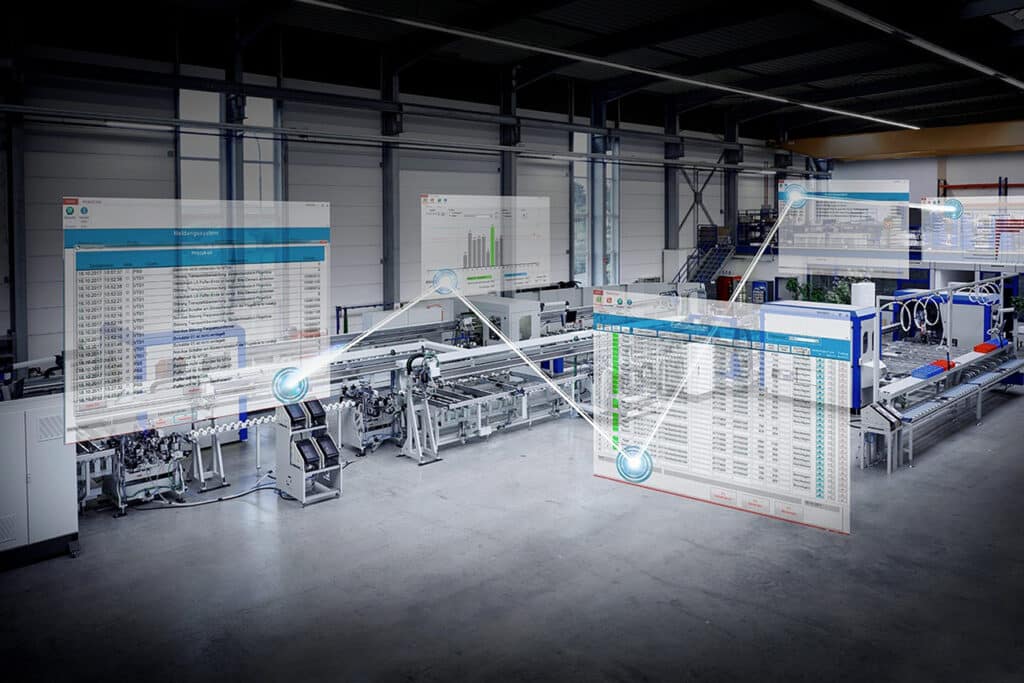

Stürtz Maschinenbau offers various solutions for machining PVC window and door profiles with a length between 650 and 6500 mm, a face width of up to 130 mm and a construction depth of up to 120 mm. The cut-off length is between 326 and 4006 mm. An intuitively operable information management system provides visualization of profile cross-sections, diagnostic and reporting tools, maintenance management and numerous other optional functions.

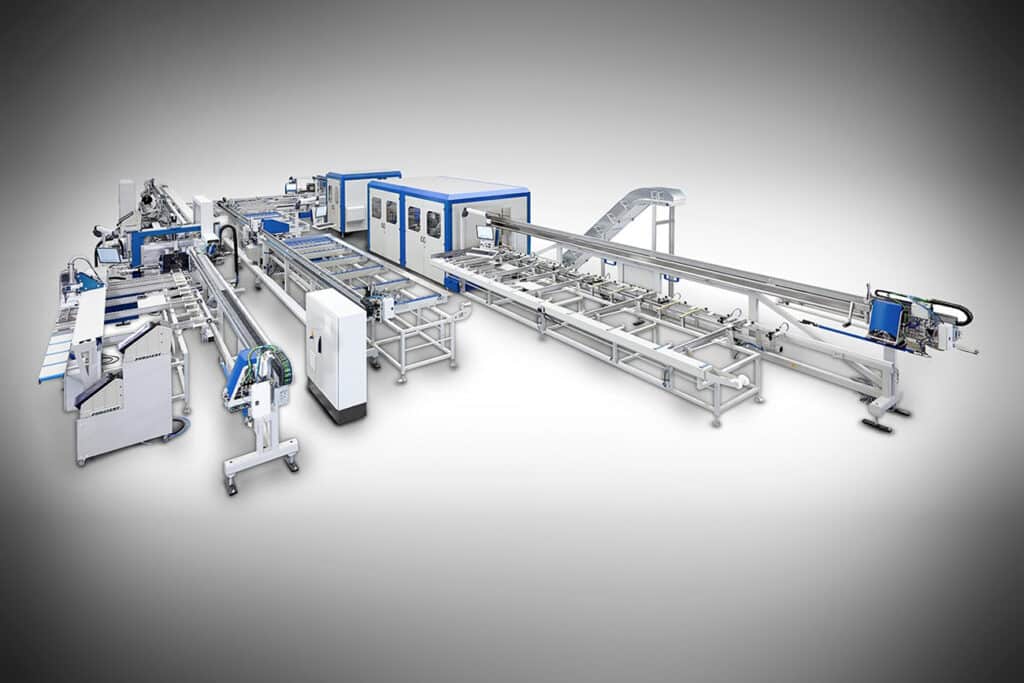

"The elaboration of a machining system depends on the application. For example, the PowerCut combines a high-performance saw automatic between an automated working feed magazine with 9 places (optionally 12) and a discharge conveyor, while the PowerCenter-100, in addition to this unit with single or multiple saw heads, also includes a stationary reinforcement screw station with 2 screw units and an element with a highly dynamic ring module. PowerCenter-PP or PowerCenter-PP-X are automated production lines with different modules and a capacity of 180 - 220 or 250 - 300 units per shift respectively. Thanks to the ParallelProcessing function, the processing of profiles can be decoupled, allowing faster work. Thanks to the modular design, the line can also be freely configured in a U, a Z or even a different arrangement at the PP-X," Boender explains.

"These machining centers for profiles can be further combined with other modules, including solutions for welding and polishing of workpieces - possibly combined in one line, an inline bellows saw for sashes, a frame corner and scissor bearing drilling station, systems for mounting sash and frame fittings, a fully automatic glass buffer and order picker or buffer and assembly systems. Depending on what the application requires, complete turnkey solutions are developed, which can also be easily controlled and monitored using the ProOpt software. So what starts with a white sheet, ends with a total customized solution."