Efficient production solutions for heroal customers

Cooperation agreement signed with Schirmer Maschinen

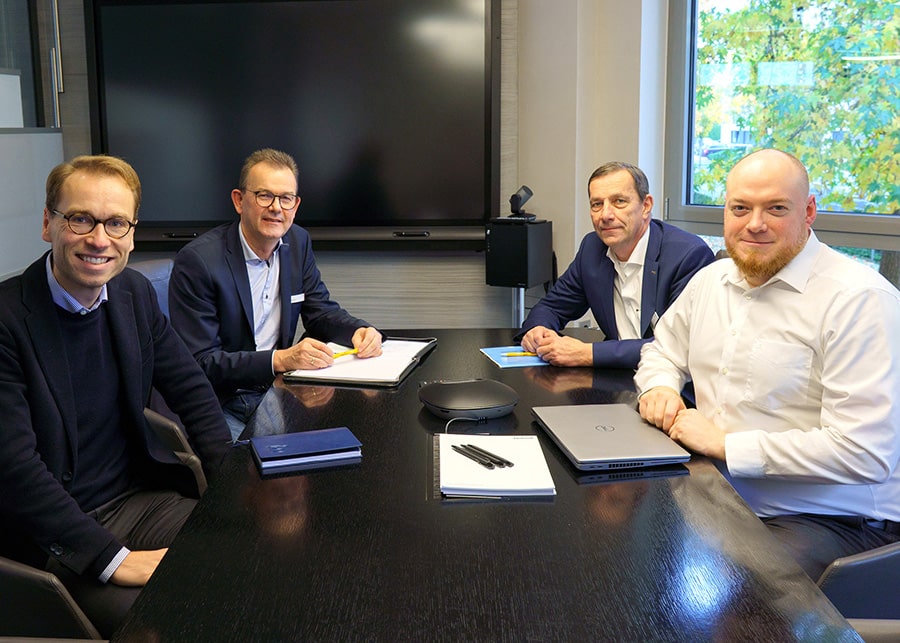

heroal, specialist in aluminum system solutions for building envelope, interior and exterior, in cooperation with Schirmer Maschinen GmbH, is expanding its service offering with highly automated and efficient custom production solutions. To this end, the managing directors of the two traditional Verl-based companies, Dr. Max Schöne and Ludger Martinschledde, signed a cooperation agreement in August 2025.

Due to the ever-increasing market requirements and the continuing shortage of skilled personnel, the need for solutions that offer process reliability and enable greater automation and thus improve efficiency is increasing.That is why heroal is already focusing on high processing efficiency of its aluminum system solutions for windows, doors, curtain walls and blinds during product development.

At the same time, heroal processors can benefit from comprehensive production consulting, which helps them realize individual production concepts that are optimally tailored to the requirements and objectives of the respective customer. Whether it is the optimization of individual process steps or the complete planning of a new production site: the development of a suitable machine concept is of great importance. This is why the aluminum systems specialist now relies on a strong partner, who is based at the same location and, in part, already works for the same customers.

Customized and software independent

The Verl-based Schirmer Maschinen GmbH company, which belongs to the Beckhoff Automation Group, configures software-independent production solutions that are perfectly tailored to customer-specific production requirements on the basis of a modular system consisting largely of standardized process modules. The machining centers for aluminum profiles have a high degree of automation and offer long autonomy times. Thanks to NC-controlled servo technology and synchronized movements, profiles can be clamped individually and processed exceptionally fast. This ensures not only precision and quality, but also high output. The flexibility with which the machines can be adjusted to very different profile cross-sections provides investment security.

Advisory concepts bundled

These are also the arguments with which heroal now recommends its systems - depending on need and potential - to customers in all existing and future markets worldwide and integrates them into their production concepts. Customers benefit from dual consulting expertise: on the one hand with regard to aluminum system solutions, and on the other hand in the optimization of their production processes.

“Thanks to Schirmer's flexible production solutions, we can support our customers in their growth,” says Kevin Meuthen, application engineer at heroal. The cooperation opens up exciting prospects for aluminum processing. “We are happy to provide our customers with expert advice on how they can integrate these technologies into their production in a practical way and what opportunities this offers,” Meuthen said. Meuthen is responsible for production consulting at heroal and can be reached by phone at +49 151 53965492 or by e-mail at Kevin.Meuthen@heroal.de.