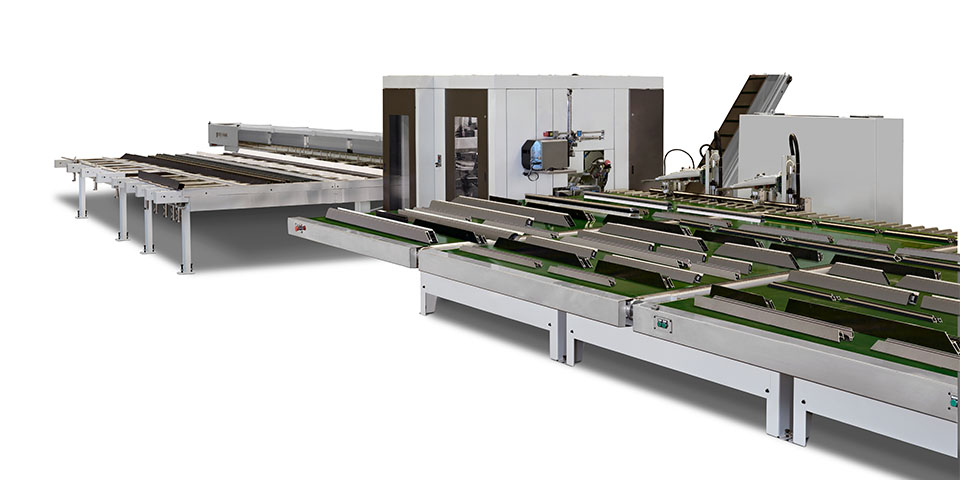

Fully automated custom production lines

Opting for faster and more accurate production

Investing in new machinery as a replacement or expansion of the machinery fleet must be done thoughtfully. The cooperation with an experienced partner opens new perspectives. Soenen Hendrik, headquartered in Izegem, is specialized in the development and production of automatic production lines for window frames in PVC and aluminum as well as fully automatic solutions for the processing of aluminum profiles for terrace coverings, balustrades and curtain walls.

The specialist also supplies fully automatic solutions for machining aluminum profiles for patio covers, for example, as well as hybrid production lines, which allow customers to process both PVC and aluminum profiles with a single investment.

Flexibility trumps PVC, aluminum, hybrid, ...

The Soenen Group, the Belgian machinery manufacturer founded in 1946, is internationally known as a producer of automated, high-tech production lines for the manufacture of window frames in aluminum and PVC as well as fully automated solutions for the machining of aluminum profiles. "We always start from a number of basic concepts and listen to the customer's needs and wishes. This is how we finally arrive at a production line, which delivers fully automated, fully machined and finished parts and frames and stocks them at the right warehouse location," says Technical Sales Engineer Jurgen Dekeyser.

"For machining aluminum profiles, used for a wide variety of applications, we can offer similar lines. In addition, we also have solutions for hybrid production lines, allowing customers to machine both PVC and aluminum profiles with a single investment."

Future-oriented and always one step ahead of your competitors

Those who invest in the intelligent solutions of Soenen Hendrik choose a far-reaching automation of the production process, where the intervention of operators is reduced to a minimum. Control instruments, including cameras, prevent any errors before and during the processing of the profiles, and since the machines are also set up automatically from the control system, operators do not need extensive knowledge to operate the whole thing.

"We are constantly expanding the principles of our Smart Machines, for example with automatic tool breakage detection and self-regulation of the system," adds the Technical Sales Engineer.

"Thanks to this innovative feature, the operations of a broken tool are automatically taken over by other tools or in other modules, avoiding machine downtime."

Soenen Hendrik develops and produces automatic production lines for PVC and aluminum window frames. A project always starts from a number of basic concepts and is then developed based on the customer's needs.

The manufacturer knows "his machine best

At Soenen Hendrik, everything is done in-house: A One-Stop-Shop. For this one can fall back on an experience of more than 60 years. R&D, sales, production, software development and integration, assembly, installation, after-sales service,..., and even transport; everything is done with our own people, from three production sites. The close contact with customers ensures that the machine builder can respond quickly to questions and adjustments. The specialists know the market through and through, so they can always offer an appropriate solution for the known pain points of other systems.

Mixed Reality: Soenen meets Microsoft

For some time now, Soenen Hendrik has been using Mixed Reality in the sales process and after-sales service. "Thanks to MR glasses we can show the customers, how the machine will be integrated in his production," concludes Jurgen Dekeyser.

"Since our machines are Mixed Reality compatible, we can provide the system with MR glasses. If the operator puts on the glasses when he has a problem, he can talk directly to one of our technical

employees contact. The latter then watches and immediately gives the remote operator the appropriate instructions to solve the problem."

SOENEN HENDRIK

Gentseheerweg 63

B-8870 Izegem Belgium

Tel. +32 (0) 51 31 28 80

Jurgen Dekeyser:

Tel: +32 (0)495/28.25.25

Pepin Carlier:

Tel: +32 (0)473/61.58.78