A start-up since 1919

Under the motto "Start-up since 1919," EVVA presented itself to journalists from eight different countries during an international two-day media event from Nov. 13 to 14.

In the spirit of EVVA's capacity for innovation, the start of the event was marked by a start-up tour of Vienna. On the second day, an exclusive press conference and tour of the Wienerberg plant allowed media representatives to gain personal insight into the location and current perspectives on future challenges and new opportunities, focusing on digitalization. In the course of the talk, Stefan Ehrlich-Adám, CEO of the EVVA Group, Michael Kiel, Executive Vice President of Operations and Johann Notbauer, Head of the Group's Market Innovation and Technology Department, reported on the most important milestones since EVVA was founded 100 years ago, new future products and production, and an outlook on the future of security technology.

Continuous innovation since its founding in 1919

The internationally renowned and recognized supplier of high-quality security systems has combined tradition with success for more than 100 years, making it one of the world's leading manufacturers of mechanical and electronic locking systems. Stefan Ehrlich-Adám, Managing Director of the EVVA Group, said:

"Since its founding as an 'institution for invention, experimentation and exploitation,' the company has been

characterized by courageous and forward-looking entrepreneurship and the pursuit of innovation."

Mechanics ...

A telling example of EVVA's innovative strength - and an important milestone in the company's expansion - was the invention and patenting of the still-important mechanical systems GPI and MCS four decades ago. However, mechanics is also constantly evolving. "Because of the patent term of up to 20 years, we are challenged to continue to develop mechanical systems and generate new ideas for locking systems," explains Ehrlich-Adám.

... and electronics

In addition, EVVA's European market development of its own electronics division demonstrates EVVA's pioneering spirit. After all, in the 1970s the Viennese family business was the first company in the industry worldwide (!) to use computer programs to calculate and operate the most complex cylinder locking systems. Meanwhile, Xesar and AirKey have been unique solutions to the challenges of global megatrends in the security industry for years. "With the entry of electronics about 25 years ago, we were there early with our own electronics development. From the beginning, we had the valuable know-how of mechanics, and to this day we strive to complement it as best we can with electronics. After all, the combination of mechanical and electronic access systems is the technically correct answer to specific security and organizational requirements," explains Ehrlich-Adám.

In-house Research & Development

The company has its own R&D department, which has grown significantly in recent years due to our ambition to conceive and develop sustainable products of the highest quality. "The engineering takes place internally, and we define the product concept. We know the market, the customers and know what solutions operators expect," explains Ehrlich-Adám.

The start-up tour passed by the Pilotfabrik Industrie 4.0, where the Technical University of Vienna is researching the production of the future together with EVVA.

Expansion and sustainability

EVVA employs about 460 people at its main production site in Vienna. In recent years, EVVA has rapidly expanded its workforce, especially in the areas of electronics and software, in addition to ongoing investments in its machinery. Ultimately, the shift from mechanics to mechatronics for EVVA also means that the company needs more technicians and software engineers. "In the future, we will also invest in an employee pool that can supervise installations," Ehrlich-Adám said. In addition to securing and creating jobs, the Viennese family-owned company is also conducting

through a focused CSR strategy. This strategy is continuously implemented by, among others,

our clean production approach, which accounts for 60%.

Global distribution partners

In addition to our headquarters in Vienna, the now ten branches in Europe and the network of more than 1,000 electronic and other mechanical distribution partners are an important factor for the further expansion and international success of EVVA. Interesting target markets are Southeast Asia, the Middle East and Australia. Locking systems from EVVA have been installed worldwide, such as on the cruise ship Queen Mary, in the Copenhagen Opera House, in the new Juventus stadium in Turin, as well as St. Stephen's Cathedral in Vienna. "Our strong distribution network is one of our greatest strengths. Our core competencies include the design, calculation and implementation of large-scale installations," Ehrlich-Adám said.

Industry 4.0 and excellence

In the second part of the conversation, Head of Operations Michael Kiel outlines EVVA's status and plans in the area of Industry 4.0. "By Industry 4.0, EVVA means not only digitization, but also the various

opportunities for developing our own excellence. For our, with Industry 4.0 connected

excellence claim, we have therefore defined four development priorities: 1. Digitalization, 2.

Automation, 3. Site development and 4. Collaboration. The highest priority here, both now and in the future, is to bring "our people" into this process through appropriate training measures and

project participation," Kiel said.

On the second day, an exclusive press conference and tour of the Wienerberg plant allowed media representatives to gain personal insight into the location and current perspectives on future challenges and new opportunities.

Digitization

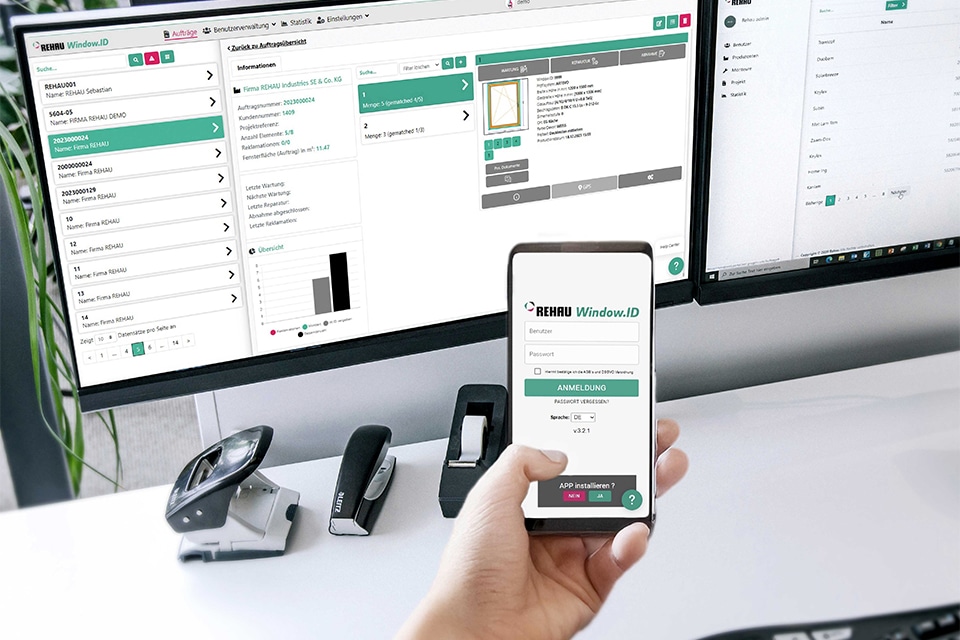

A showcase tool for "living digitization" is EVVA's self-built Order Fulfillment Tool, which displays the status quo of orders for order management. EVVA is pursuing several goals in the Next Generation Cross Link Production (XPro) project: On the one hand, a blueprint for a flexible production system is to be realized, for which EVVA, in cooperation with the Technical University of Vienna, has 'digitally enhanced' a machine and additionally equipped it with collaborative robotics. On the other hand, digitization is becoming "paper- and drawing-free. This is enforced with computer-aided manufacturing (CAM), which is already being used for prototyping. Ultimately, the medium-term goal for EVVA is to make production, for planning and optimization of processes, completely digital with 'Digital Twins'. As part of the AutProSim research project with Fraunhofer, digital production planning with simulation and optimization is to be implemented from 2020.

Automation

"EVVA is investing 20 million Euros in the development of excellence until 2023. Of this, two-thirds will be

spent on high-quality automation solutions," Kiel said. Particular emphasis will be placed on new technologies 3D printing of plastic parts for machine building, and image processing for a test scenario integrated into the automation system. EVVA will also increasingly use cooperating robots (Cobots) to help workers with simple monotonous tasks (such as sorting).

"With these automation activities, activities and consequently orders from low-wage countries can be brought back to the Wienerberg location. In addition to reducing errors and increasing the

training level, Cobots also make it possible to increase EVVA's competitiveness," explains Michael Kiel.

Site development

Kiel goes on to explain why Industrie 4.0 at EVVA is linked to internationalization. "With regard to our Power Plant strategy with satellite locations, three locations, namely Vienna, Tišnov and Krefeld, will be in the

future become Power Plants and thus production units for parts production and

automated assembly. In the future, our satellite locations will consist of eight

European sales locations for manual assembly of smaller batch sizes."

EVVA plans to make all Power Plants and satellite sites one unified

process chain to make.

Collaborations

In conclusion, Kiel outlines the various collaborations with a research character as the fourth development priority on the road to excellence. As part of the Pilot Factory 4.0, feasibility studies are being developed with TU Vienna on the application possibilities of Cobots or machine-to-machine communication solutions in production. With the Fraunhofer Institute, EVVA is investigating solutions for automatic production planning and optimization based on live production data. In turn, the University of Vienna supports EVVA in the development and expansion of the centurio.work production platform. In addition, EVVA is a co-partner of the Austrian Center for Digital Production (CDP), which, among other things, pursues the research objective of continuous digitization from order and production to delivery. "For EVVA, however, the objective of excellence development consists not only of continuous development, but also of regular positioning. For example, next year EVVA wants to be leading in the industrial benchmark 'Fabrik 2020 - the best production in Austria'," Kiel says in conclusion.

Looking to the future

Finally, Johann Notbauer, Head of Market Innovation and Technology, reported on trends and developments, also based on recent impressions at the companies ARM and Microsoft in Silicon Valley. The possible scenarios are based on two future technologies: 1. Artificial intelligence and machine learning

(AI/machine learning) combined with 2. Connectivity. Both topics are also associated with, for the security industry, disruptive changes.

Machine Learning

For the innovation driver machine-learning, the disruption, according to Notbauer, is that in the future the devices will be "intelligent" - migrating the processing and evaluation of continuously determined data to the devices themselves. Further diverse application possibilities arise from the combination of digital with physical data. "In the future, for example, all 'intelligent' end components in a Xesar system can continuously measure their own voltage curve, and in turn this data can be centrally evaluated with a 'neural' network. The algorithm thus established detects when and at which end component a battery failure occurs. This in turn optimizes plant sustainability and maintenance costs and provides the company with valuable information needed to modernize the overall system. The added value and benefits for the customer consist of 'Predictive maintenance', i.e. trouble-free operation combined with cost-optimized maintenance," Notbauer gives as an application example at EVVA.

Connectivity

The second major driver of innovation is connectivity, as a result of the many new opportunities offered by the gamechanger 5G. "5G offers us the ability to connect production machines directly to the cloud

close. A local programmable controller is no longer needed to program. This is done in a

central cloud. It can be quickly set up and adjusted as products or market demand change," Notbauer explains. This trend is called "Control as a Service. But despite machine-learning and 5G, EVVA will continue to develop the innovation of mechanical systems alongside the benefits of new technologies, because a mechanical element still remains at the end of the chain.