Presentation at Polyclose. 'Even with a more limited budget, the step into the CNC world is possible'

Today's manufacturing industry is characterized by an increasing demand for small, compact and lightweight machines, sometimes called entry-level machines. This allows companies to take a big step toward automatic machining of profiles without substantial investment.

"With the SBZ 118, elumatec's R&D department has developed an innovative 3-axis profile machining center with optional 5-sided machining, which combines the speed and versatility of larger machines with an extremely compact design," says managing director of elumatec Benelux BV Bas Ladestein. "At Polyclose, we are putting the full spotlight on this great addition to the lower end of the range!"

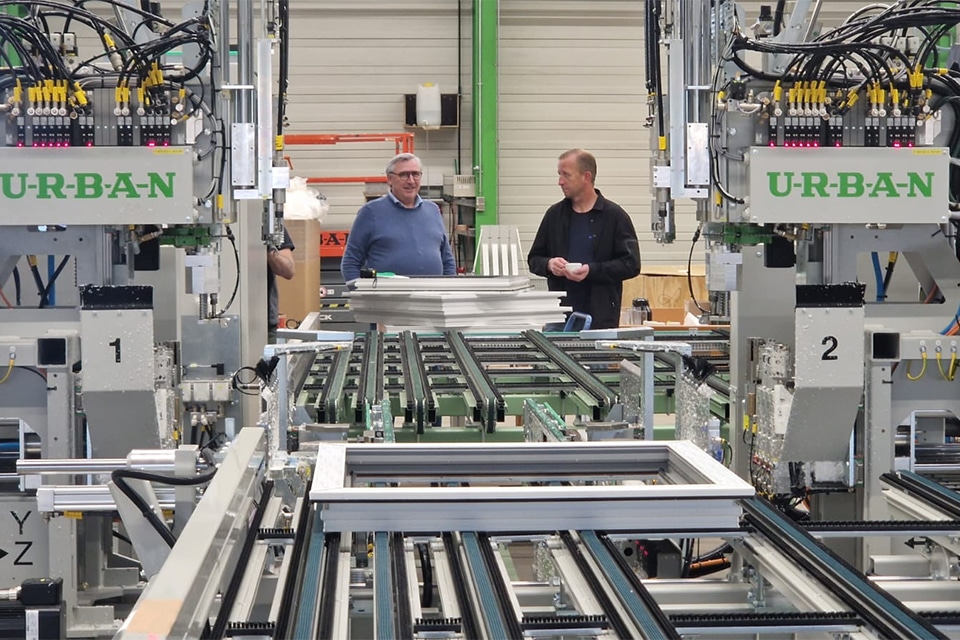

"Elumatec is one of the world's leading providers of machinery for processing aluminum, plastic and steel profiles," Ladestein says. The range includes sawing machines, stop and measuring systems, profile processing machines, angle joint presses and assembly and workshop equipment. The range is divided into families, such as the SBZ 14x, the SBZ 122 and the SBZ 628. Within each family, chassis and body are the same, but based on customers' wishes and needs, elumatec can provide customized systems.

"The drive for innovation is one of the cornerstones of our success," says Ladestein. "In doing so, we work closely with our customers and listen to their needs. This enables us to constantly develop new solutions or optimize our existing products. With our comprehensive product range, we cover the entire spectrum of users, from the small design engineer to the industrial profile processor. Start-ups or smaller manufacturing companies in many cases do not need high-end machine tools. They are looking for a small and compact system with all the necessary functionalities for their applications and also at a lower entry cost. With our new profile machining center SBZ 118, we are responding to this and making a perfect start in the world of CNC machines possible for everyone. The prototype was shown at the last edition of Equip'Baie in Paris, but at Polyclose we are putting this entry-level model fully in the spotlight. It is immediately a nice extension at the bottom of our range."

Fast and versatile, but also compact

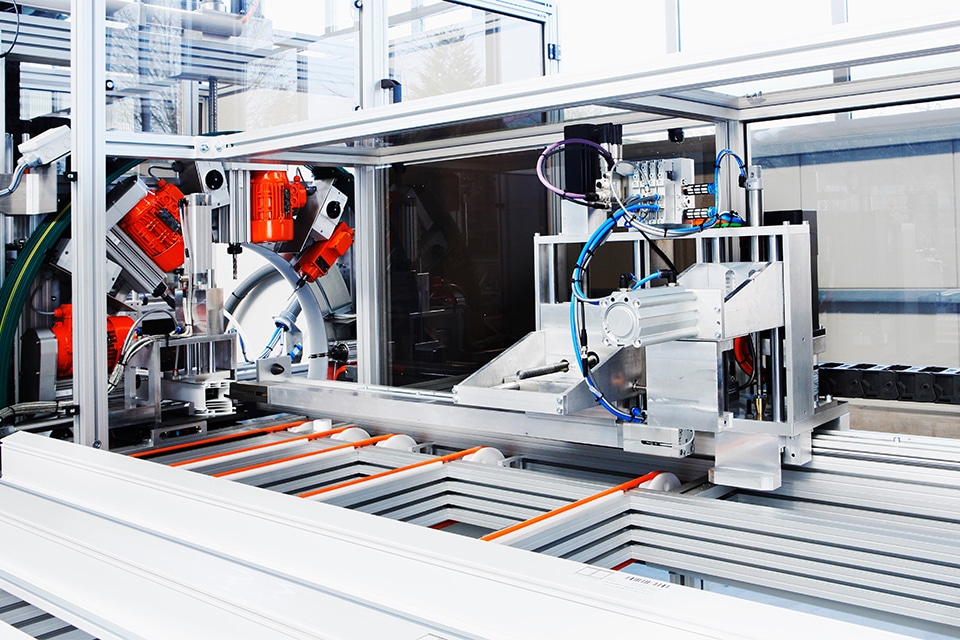

The SBZ 118 has a machining length of 3000 mm, making it the most compact CNC machine in elumatec's current portfolio. It has a reach of 3246, 942 and 366 mm in X, Y and Z axes, respectively, and is equipped with a spindle with an output of 5 kW and a speed of up to 24,000 rpm. "Even at high speeds, accurate machining remains guaranteed," said Ladestein.

"Although this machine has a minimal footprint, it still provides full functionality for milling, drilling, tapping and roughing," continued the Managing Director. "Automated CNC machining is performed on up to five sides with an optional right-angle milling head and end mill. The proven technology of the inclined machine bed, the freely accessible spindle, the height-adjustable control console and the mobile five-way tool changer increase comfort. The new transparent protective cover and operation of the material clamps via a wireless push button ensure safe operation at all times, even for larger operators. A service door on the side facilitates setup and maintenance of the machine."

Ready for Industry 4.0

According to Ladestein, the SBZ 118 is therefore an ideal solution for manufacturing companies that want to take the step to automated CNC machining. "But the machining center can of course also be a possible extension to the machine fleet of companies already using larger elumatec systems."

"As with our other machining centers, we based the development of this entry-level model on the requirements of our customers. After all, they should always be able to configure the machines in detail for their purposes. This is precisely why this SBZ has 118 configurable equipment options. You can choose from up to two mobile tool changers for right-angle milling heads, an expansion of up to six material clamps, an additional stop with overlength processing and a barcode scanner. This SBZ 118 is also eluCloud Ready for the requirements of Industry 4.0, making this machining center from elumatec ready for the challenges of today and tomorrow," concludes Ladestein.