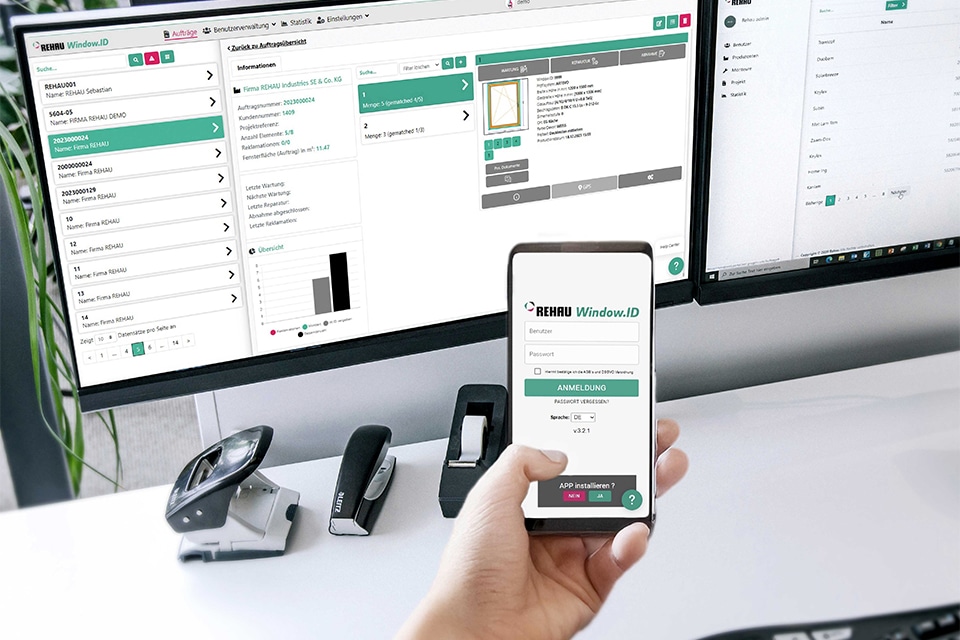

Those who keep track of everything on paper for a project lose a lot of time

Customers are becoming increasingly demanding. Ultimately, firms can only cope with this by betting on a paperless, digital organization of all processes.

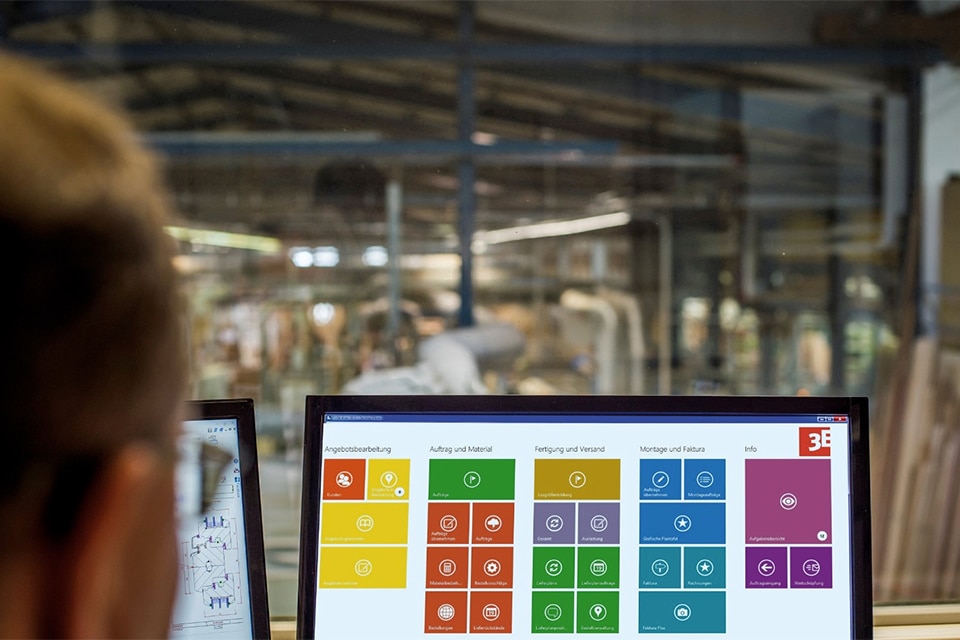

Klaes has been developing innovative software solutions for window and door manufacturers and conservatory builders for many years. A multifunctional tree structure with all documents forms the core and is further complemented by intelligent solutions, such as the Klaes Info Manager, DMS Integration and e-prod.

Targeted communication

The Klaes Info Manager organizes and optimizes workflow and also transitions between different business processes. This tool takes care of the necessary communication between the employees in the office, on the job and on the shop floor and saves a lot of time and work through automation. Each employee can always access notes, assignments, messages and other information in an organized manner through personal dashboards, a team overview, client data and project files. All necessary information is available to each person involved at any time. For example, when the delivery note is created, an e-mail with the further steps is automatically sent to both the customer and the field service employee. At the same time, logistics employees are instructed to prepare the shipment.

All documents at your fingertips

Anyone who keeps track of everything on paper for a project loses a lot of time. Thanks to Klaes Document Management, paper documents are automatically converted to data in a digital workflow. They are merged with all other available data and mails. In this way, time-consuming document management is minimized. Tasks such as checking, signing or approving are customized individually for each company with a graphical workflow configurator. The workflow becomes shorter, as several tasks can be performed at the same time, since everyone involved in the project can also access and modify all documents and files. With this intelligent software tool from Klaes, all information is automatically stored in the right place and filtered by client and project, making daily tasks much more efficient.

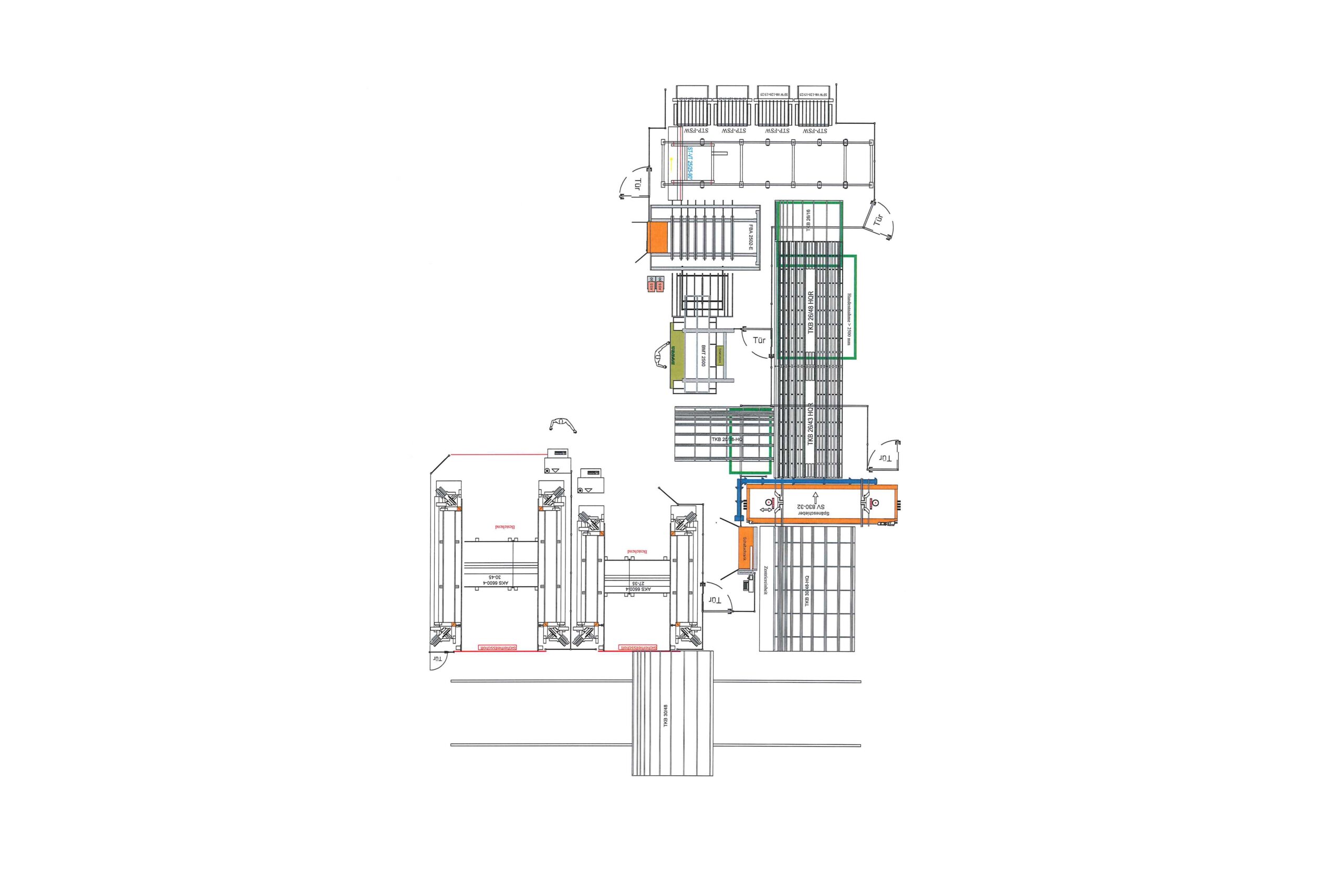

Producing from a network

You just have to think about how much time it takes every day to write down, sort and distribute information about productions, how often the right information, parts or materials must then be searched for on the shop floor, or how often parts are in short supply on a job site, necessitating additional efforts. Then it quickly becomes clear that a good digital information system via the network can only benefit all involved.

Klaes e-prod primarily takes care of the distribution of data in production. At each workstation, those involved get to see exactly the information that is needed at that moment. In some cases, images, drawings and sketches or complete files are also made available. With each completed stage, the necessary comments are attached, which are then automatically available to the employee in the next stage.

Adjustments are made in no time - with a few mouse clicks, data are removed from the system and replaced with others. Via the "quality management" tool, those involved also receive information about any errors and how they were resolved. Continuous quality control during the production process can also be carried out automatically.