ReFace simplifies reuse in facade construction

On August 26, the ReFace project was launched. Five pilots should simplify the process of high-quality reuse of façade products and residual streams.

The facade industry wants to make a positive contribution to the world of tomorrow. It is moving towards a circular facade economy in which products and materials are reused. For high-quality reuse, it is necessary to know exactly what façade elements, products and materials are released and where and when. The quality must be sufficient and it must be determined whether and how it can be reused. In practice, the right knowledge and information about this is hard to find. The pilot projects in ReFace should provide insight into how this can be improved.

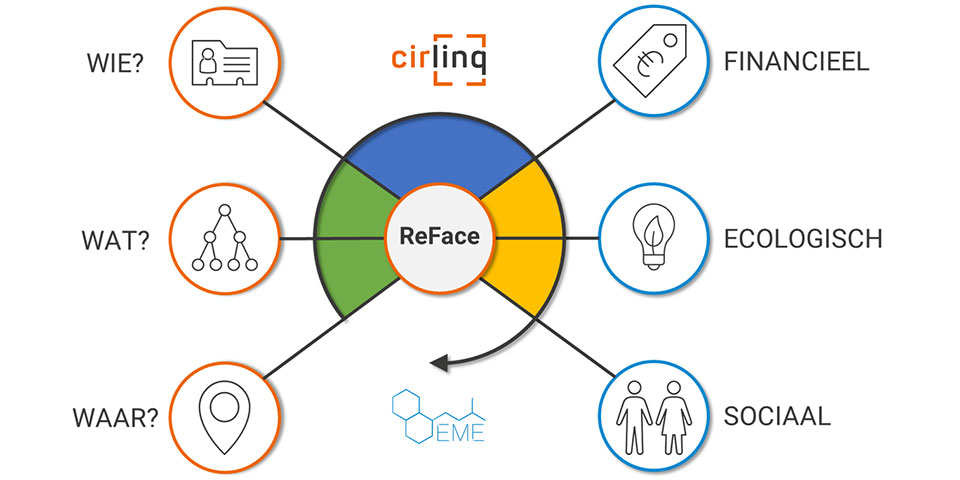

ReFace provides insight into the financial and ecological value of products and materials from facades using product and material passports. This involves finding the right match between demanders and suppliers of products and materials that can be reused. It also looks for new applications for existing facade products and residual streams from factories.

ReFace is a collaboration between Cirlinq and Excess Materials Exchange (EME). This collaboration is based on four pillars:

- Register of existing and new facade products as well as residual streams in a product and resource passport;

- Identify and tracking using identifiers (QR, NFC & RFID);

- Rating by providing insight into the financial, environmental and social impact of reuse potential;

- Connect By seeking and realizing a high-quality match.

The pilots involve the following project partners: Hydro Building Systems, Pilkington, Panelen Holland, GEZE, Lecot, Alkondor Hengelo, VMRG, New Horizon and Alba Concepts. The pilots will run for 5 months and provide insight into the feasibility and scalability of the various recycling and reuse options in practice. ReFace contributes to a reduction in CO2-impact of the facade industry and leads to increased reuse of facade elements, products and materials.