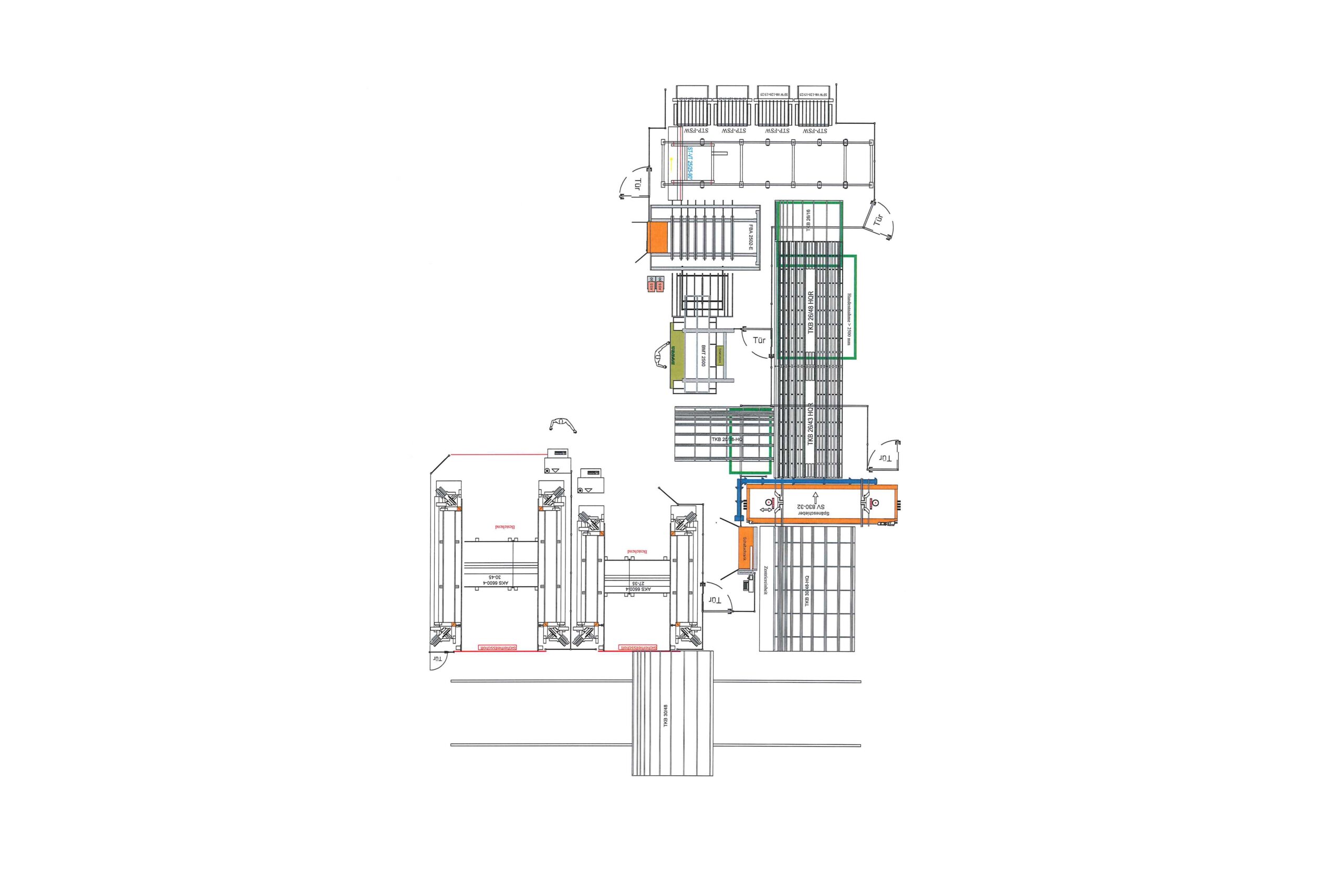

The direct link between desk and shop floor, between drawing, preparation and production

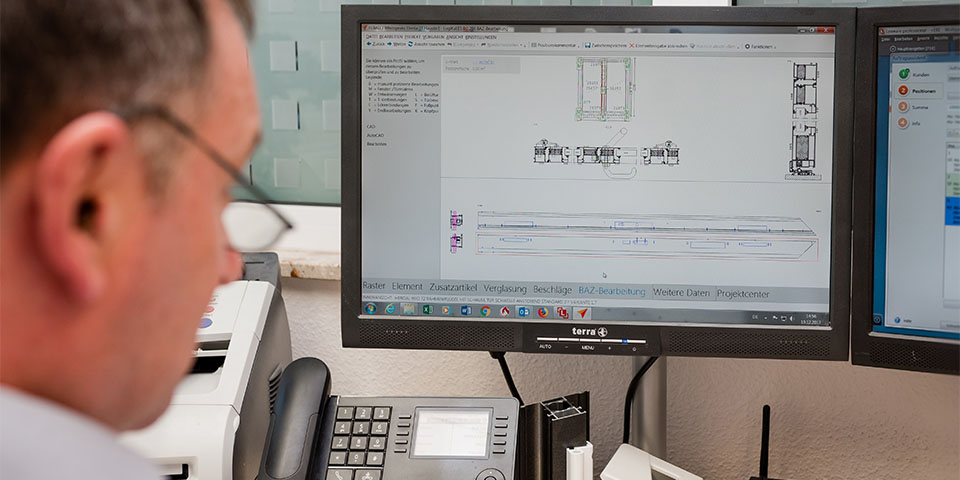

Good connections are important, and so are computers and machines. Orgadata's Logikal software package, which is used by a lot of window manufacturers, door manufacturers and facade builders, provides the perfect link between the computers in the offices and the CNC machines on the shop floor, even at companies in the metalworking sector.

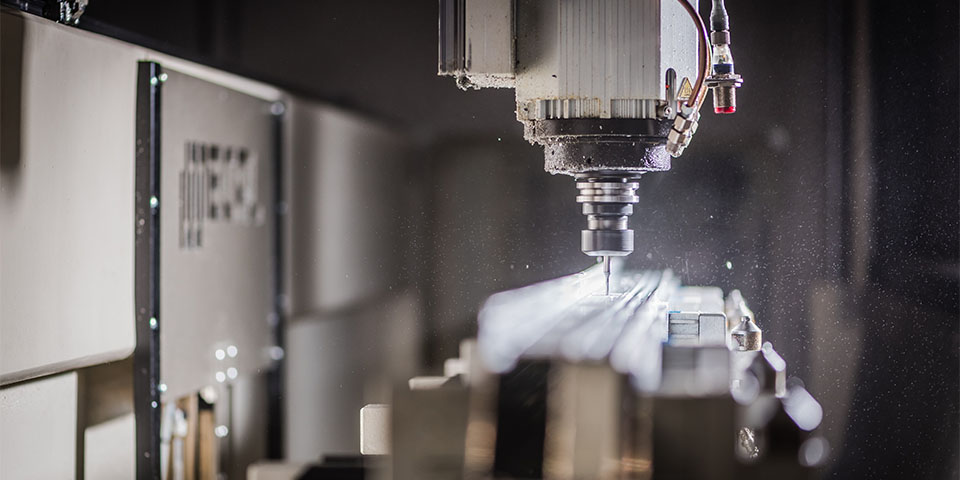

That link between desk and shop floor, between drawing, preparation and production is like the icing on the cake of design and calculation software Logikal. After all, the program can directly control the machines of different manufacturers. This eliminates the need for additional programming at the machine, which increases efficiency. The digital combination of components and profiles in Orgadata's software package allows computer and machine to communicate with each other. For example, if a particular profile is selected for a door and the draftsman adds a lock from the library, the geometry of the lock also directly determines the operation to be performed in the profile.

The machine automatically receives the information, so to speak, where to perform which specific operation. For example, it knows exactly where to mill a slot in the profile for the lock or drill holes for the fastening screws. Profile, lock, screws and handles fit together perfectly. Orgadata has literally pre-programmed the successful combination of the various components.

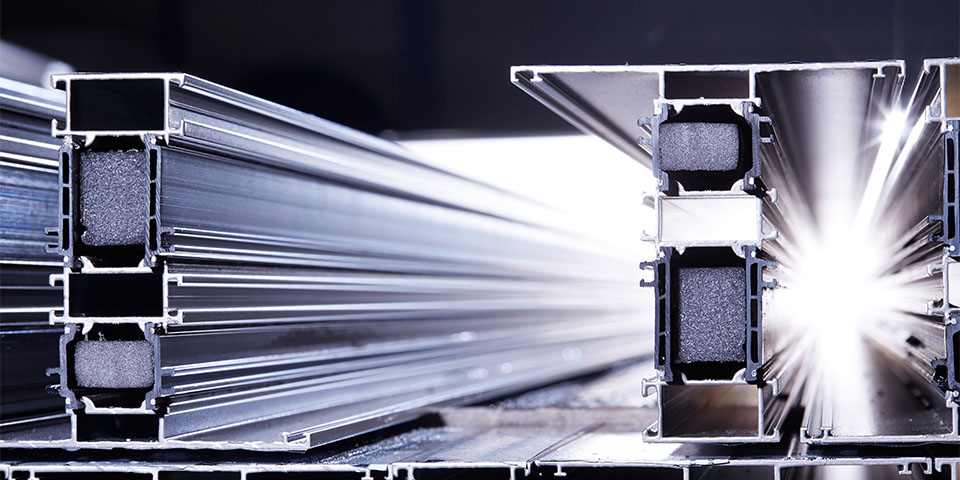

Drawings for production can be sent directly to the machine on the shop floor.

(Image: FeuerQuell Photography)

Cooperation with operators and machine manufacturers

When setting up the machine, specialists from software house Orgadata work together with the operator and the machine manufacturer. In the process, the cooperation between software and machine can even be prepared for special applications. If unprecedented operations occur during daily operation, the program is adjusted in close consultation. The direct link between the draftsman's computer and the machine via the software ensures increased efficiency.

"Customers tell us time and again that machine productivity increases by about 30% as a result of controlling with our software, and there is still a lot of room for improvement," Paul Thyssen tells us with some pride.

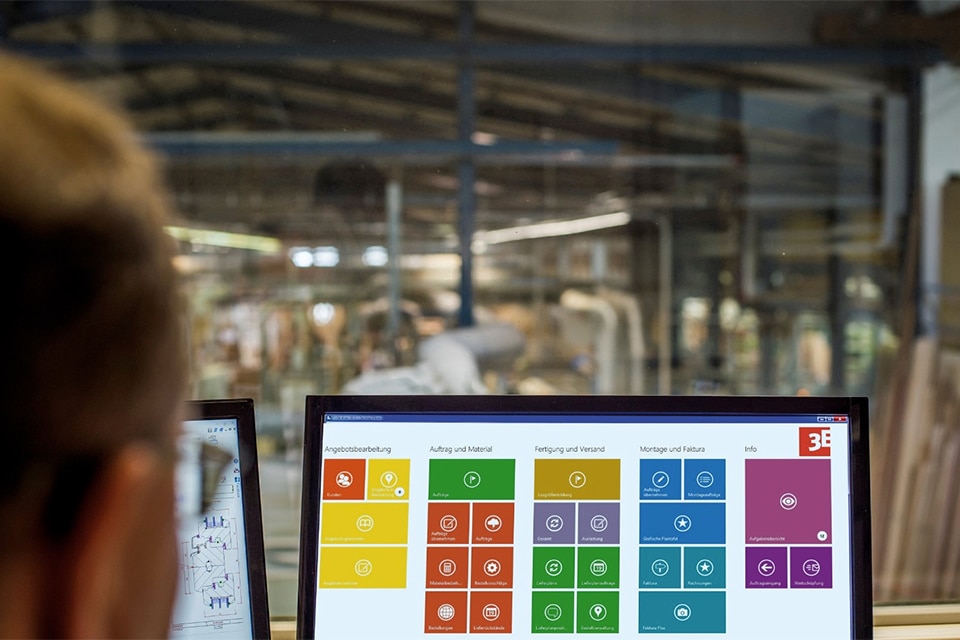

"In addition to reliability, improved efficiency and higher productivity are important assets in every case, which is why interest in Logikal continues to grow in the window and door manufacturing and facade construction sectors. The popular program offers reliable assistance in all stages of production. It supports the user comprehensively from project entry, estimation, quotation, drawing and work preparation to the intelligent control of CNC machines. The software guides the user step by step in the development of a project."

The software package Logikal is an ideal solution for editing profiles. (Image: Torsten Kollmer)

The metalworking sector

The metal processing sector also likes to use Logikal because the software allows it to process the products of the most diverse manufacturers. Indeed, the extensive and up-to-date library contains the products of the best-known profile and hardware manufacturers from the aluminum, steel, wood-aluminum and plastic sectors. In addition to profiles and fittings, one can also find glass and accessories, with all possible information including current price and stock. Without Logikal, metalworkers would hardly be able to keep up with the complexity of and rapid changes in the sector.

The wide variety of data is a unique selling point for Logikal. Metal processing companies can edit their suppliers' profiles with only one software. This saves work, time and therefore money.

One thing is clear: because of the above advantages, processors are choosing Logikal en masse.