Successfully going against the grain

The profession of window manufacturer cannot be underestimated. In the past, various factors have caused companies to cease production and continue as distributors. But it can also be the other way around. The company Setz Fenster GmbH & Co. KG. Founder Philipp Setz started distributing windows in 2009 and only later began producing high-quality windows himself at the request of his customers. To do so, the team uses Klaes' flexible software.

When Philipp Setz started distributing and assembling windows in 2009, it was only as a sideline, as he also continued to work as a salaried carpenter. "I only stopped there in 2014," says the business manager. "The window business kept growing and I had to make a choice." The business manager increasingly found that it was not easy to simply adapt standard windows to the circumstances of each specific application. There was a need for individual customized solutions.

Thanks to a team of experienced employees, the company manages to deliver the finished windows in 24 hours.

"We did not want to limit the choice for our customers to one system and offer them an efficient, feasible customized solution," Setz continues. "Besides the quality of our products, flexibility in particular is the key to success. We have many customers who build turnkey homes. Those obviously can't wait four weeks to continue working because the windows don't fit and have to be replaced. In order to supply those companies at short notice, we started our own production. Now, if a window is short on a job site because it was damaged or the construction was modified, we can provide an appropriate solution in a few hours."

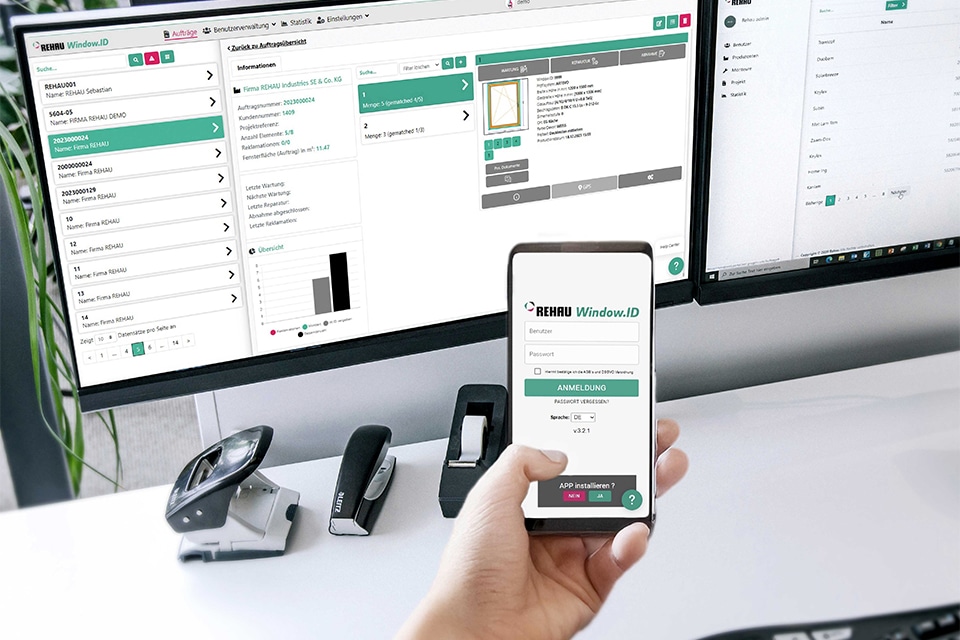

The move to digitization

In the beginning, everything was done manually, on the shop floor, as well as during preparation. Software was not used anywhere. But the demand continued to grow and Setz realized that this outdated way of working resulted in a lot of wasted time. So the manager started looking for suitable software and found IT specialist Klaes. After all, the Rheinland-Pfalz-based company is one of the market leaders in software for the production of windows, doors, facade systems and conservatories and can offer a suitable software solution for every type of company and application. "We invested in a machining center from ROTOX and for this we also had to look for an optimal solution for control," Philipp Setz explains. "Our contacts with the people at Klaes showed that they attach enormous importance to good training and support for the operators, and we knew only too well how important good service is during implementation."

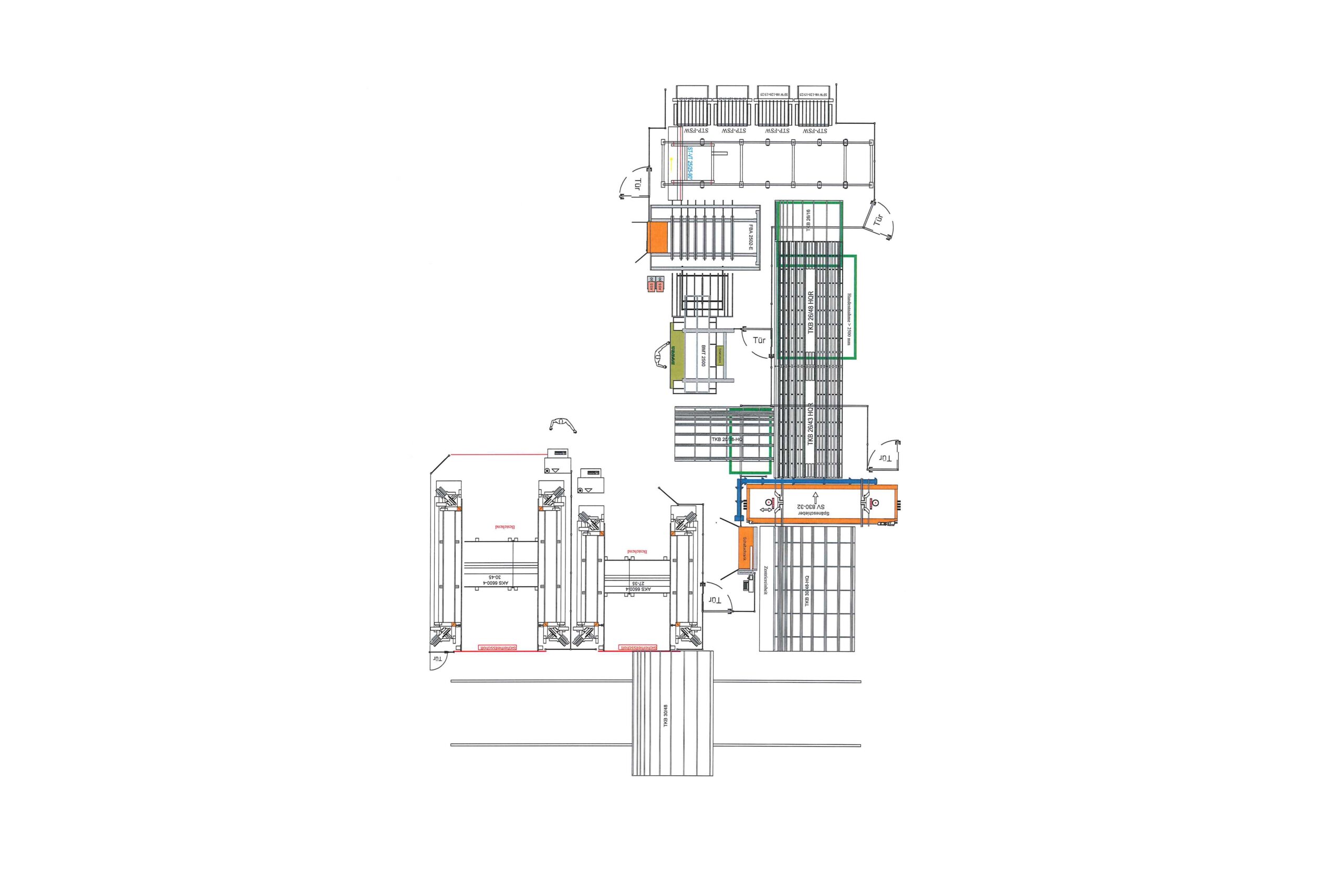

Efficient lifting equipment ensures optimal transport of heavy parts in production.

The best support

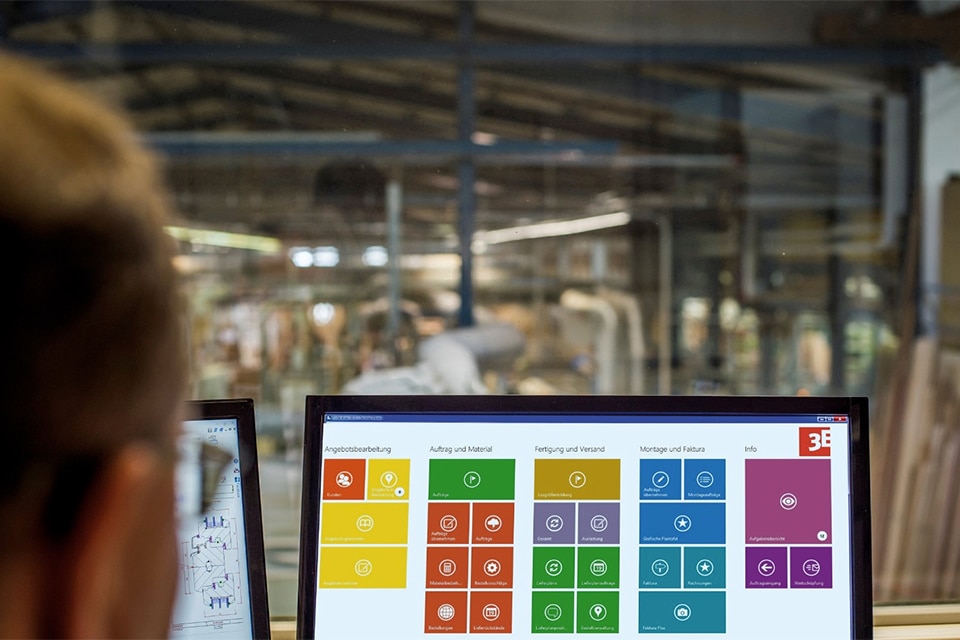

Philipp Setz and his team did a lot of research beforehand. Time and again, Klaes was recommended. In the end, they went with the specialist - a decision they have not regretted to this day. At the Fensterbau Frontale 2018, the first agreements were made and three months later, with the klaes vario, the window manufacturer received a suitable software solution that meets today's requirements and in can be expanded in the future. "Since August 2018, we have been using Klaes' software for making calculations, preparing quotations, ordering materials, printing production lists, working out invoices and controlling the machines," states Managing Director Setz. "And that is clearly bearing fruit."

Philipp Setz and his business partner Carsten Hennrich in front of the ROTOX machining center on the shop floor.

Looking to the future

More and more turnkey construction companies are knocking on Setz Fenster GmbH & Co. KG, and inquiries through resellers also continue to grow.

"Actually, the demand today exceeds our capacity, even though we can work much more efficiently thanks to our Klaes software," Philipp Setz concludes. "That is why we are building a new production hall, which we will commission at the end of the year. The capacity, which so far has doubled just about every year, still needs to increase a lot more to be able to serve all customers on time."