Flexible response to market needs

To continue to meet customer needs, facade builders, window and door manufacturers and other metalworking companies can often perform highly complex operations on the profiles. Therefore, it is important for their machinery to be able to operate with increasing power, ingenuity and precision.

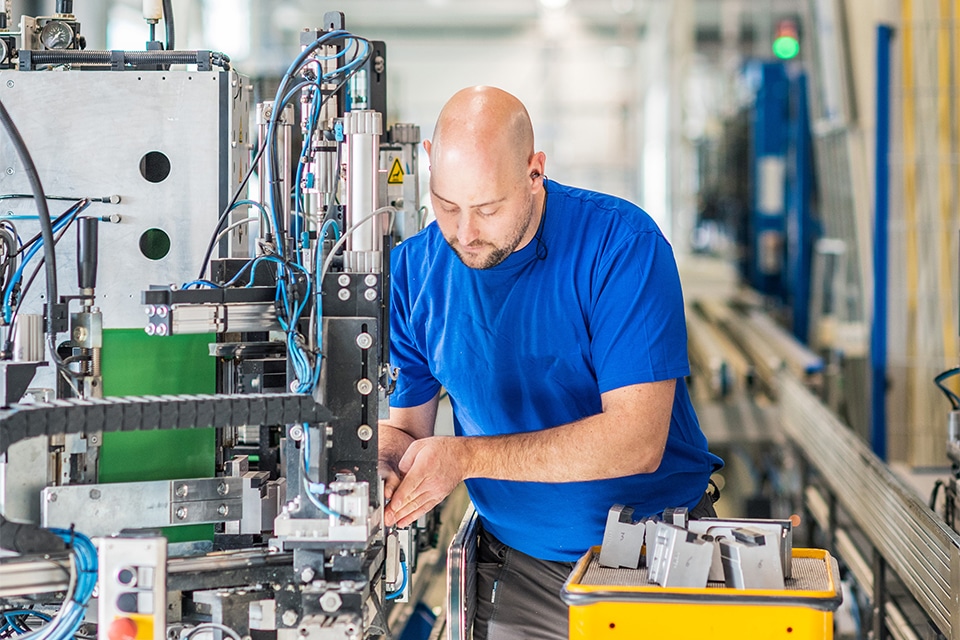

The SBZ 151 Edition 90 is equipped with a new material clamping system.

As a specialist in the field of profile processing machines, Elumatec repeatedly strives to come to market with innovative solutions that perfectly meet those needs. At BAU Munich, this market leader once again presented some striking novelties, including a special Edition 90 of the SBZ 151 machining center and the SBZ 628 S pass-through machine.

Elumatec is an international market leader in the development and production of machine tools for aluminum, plastic and steel profiles. Especially for the anniversary year, Elumatec restyled its successful SBZ 151 machining center.

Elumatec started in 1928 with the production of light metal sand castings. Today, the company has become an international market leader in the development and production of machines for machining aluminum, plastic and steel profiles. "This company has more than seven hundred employees and has its own subsidiaries and dealers in more than fifty countries around the world," says Bas Ladestein, managing director of Elumatec Benelux BV. "Thanks to all available knowledge and experience, we can be innovative again and again. We listen to market needs and our R&D department converts them into innovative solutions. So today we offer a wide range: from simple manual machines to complex profile machining centers. However, we also provide tools, such as conveyor systems, tools, assembly equipment and software."

Unpacking at BAU Munich

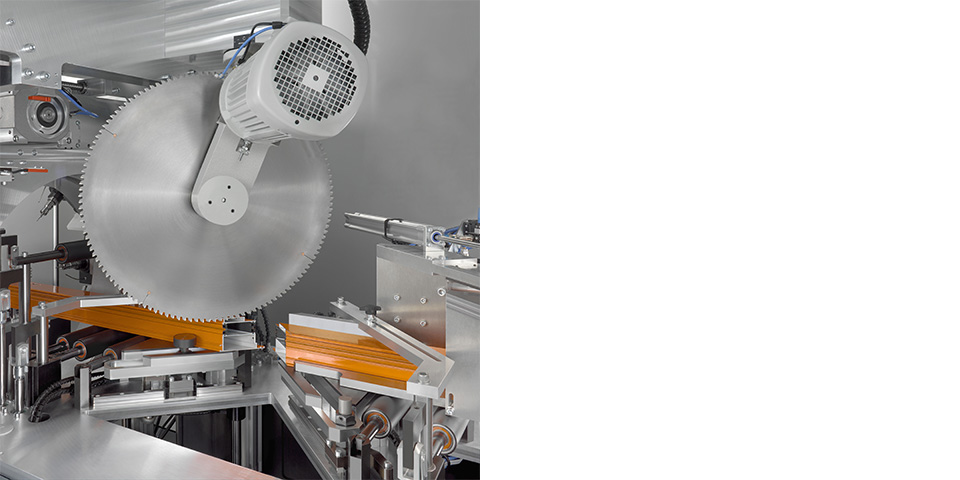

Another innovation from Elumatec is the profile machining center SBZ 628 S, the little brother of the XL and XXL versions.

Even after 90 years, Elumatec remains a young and dynamic company with an emphasis on innovation. This was once again evident at the BAU trade fair in Munich, where the specialist presented many new solutions. These included the SBZ 122/70 Plus 3-axis machining center and the powerful DG 244 double miter saw.

Thanks to the continuously slewing 2-axis saw blade, maximum profile cross-sections of 200 x 160 mm or 160 x 200 mm can be cut with the greatest accuracy.

"Especially for the anniversary year, we also restyled our successful SBZ 151 machining center. This Edition 90 includes all the proven advantages of the all-rounder, but in a new, modern design as well as with new improved material clamps," states the managing director. "With this machine, profiles up to 30 m long can optionally be machined. All operations, such as milling, drilling, tapping, threading, and sawing are done on a stationary clamped profile, protecting the surface as much as possible. With the optional right-angle milling head, profiles from all six sides can be machined in a single clamping operation, and a ride-on tool magazine speeds up tool changes. In addition, this SBZ 151 Edition 90 is 'eluCloud Ready,' which opens doors to Industry 4.0 and the Smart Factory."

A rotating ring with 4 spindles allows profiles to be machined at any angle between 0° and 360°.

A new addition to the SBZ 628 model family

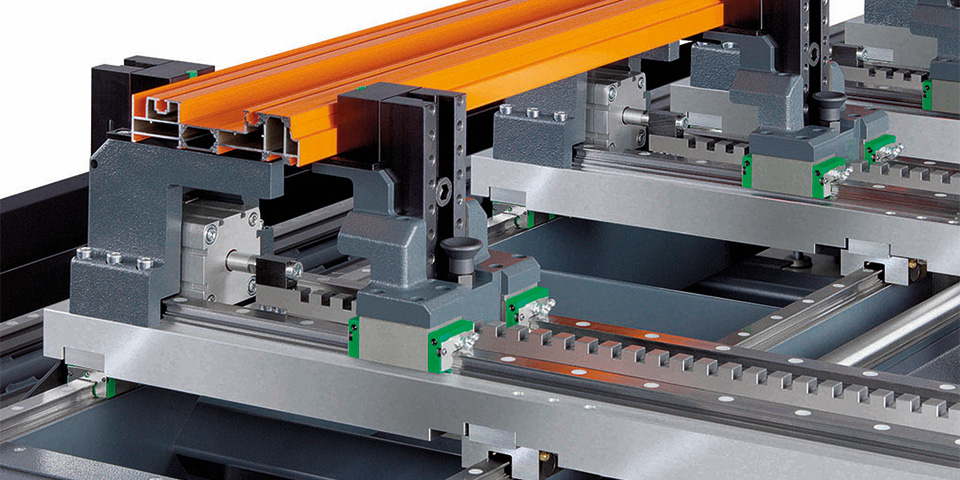

A look inside the SBZ 151 Edition 90, where all kinds of machining operations, such as milling, drilling, tapping, threading, punching and sawing are done.

Another innovation from Elumatec is the profile machining center SBZ 628 S, the little brother of the XL and XXL versions from this successful model family, which the specialist itself likes to call the Rolls Royces of machine tools. "This affordable entry-level model offers great flexibility when machining and cutting profiles. The feed magazine holds 5 to 10 profiles with lengths between 3 and 7.6 m. A patented profile gripping system brings even the most complex workpieces into the correct position for machining," Ladestein explains. "A slewing ring with four spindles ensures that profiles can be machined at any angle between 0° and 360°. Thanks to the continuously pivoting 2-axis saw blade, maximum profile cross-sections of 200 x 160 mm or 160 x 200 mm can be cut with the greatest accuracy."