The future of window and door manufacturing is ... robotization and automation

Solving industry's skilled labor shortage remains biggest challenge

"At Polyclose, we show customers the possibilities of robotization and automation," says Dennis Koning of Tryma Netherlands. Together with Jasper Neirynck of Tryma Belgium, he is at the fair where they want to offer companies a solution to the personnel shortage.

"The shortage of skilled workers remains a big problem, we see it everywhere and it cannot be solved just like that," Dennis Koning says. "We also see this in Belgium," adds Jasper Neirynck. "Not only the lack of good personnel but also the rising labor costs and the aging population are problems our clients are facing."

Robotization as a solution

The production of windows and doors is still quite traditional at many companies, according to King. "Compared to the automotive industry, for example, there is still little use of robotization. Many of our customers did invest at the front end such as profile machining and sawing. But there is still a lot to be gained in the rest of the process and that is where Tryma can help."

Neirynck: "Thinking along, providing tailored advice and helping the customer further in the area of automation is what we do. We see companies now that a lot of time is lost with, for example, the logistics of a product; packing, putting away and moving. If that goes automatically then you can spend this lost time on actual production. Tryma's principle is that one person at a workstation should be able to perform all the operations alone."

"The element comes to the person instead of people having to walk around and search," says King. "In addition, we apply robotization in production. Think of the automatic placement of hardware parts by robotic arms or the application of rubbers. An additional advantage of this is that ergonomically it is also better for the staff. They are relieved and that makes working more pleasant. People can keep doing this work longer this way, and it ultimately saves on health costs as well. The lighter the work becomes, the less chance of staff dropping out because of physical complaints."

Customized logistics solutions

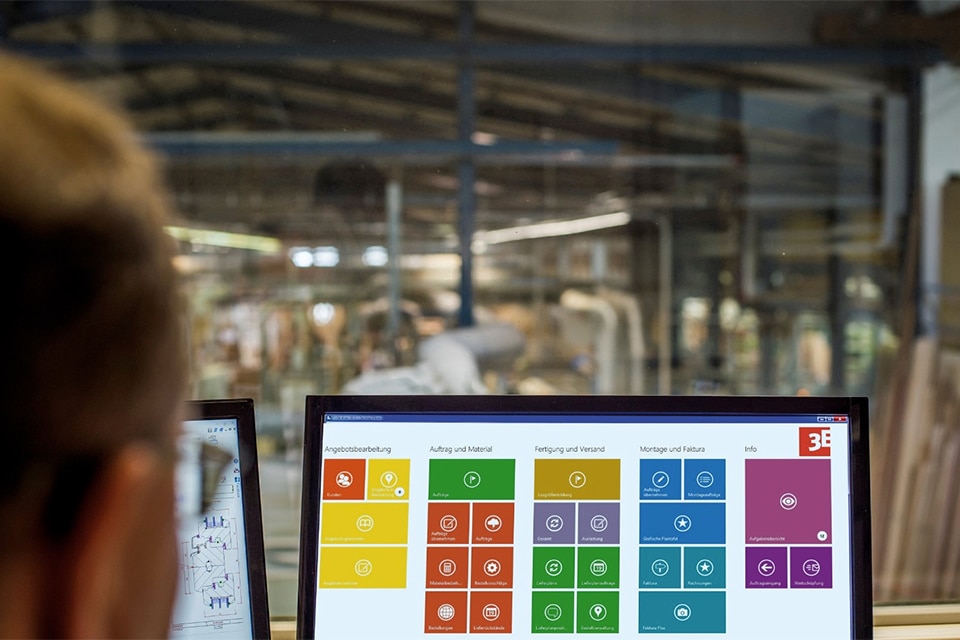

"Each company has its own unique requirements and budget. To best meet the needs of our customers, we created Tryma Poland. Here we produce our own logistics solutions," says Neirynck. "We work out the customer's layout and integrate our own transport and buffer system. Either manually or automatically. Because Tryma is also a dealer of other manufacturers, we can offer a complete production line. We advise our customers on the best process layout and supply the necessary control software if necessary. Many companies still think they need to invest heavily to optimize production but fortunately this is not the case. Even a limited investment can make a big difference."

Dennis Koning: "Because even though robotization still sounds like something for the future, a lot is already possible now. We are not just about selling the right machines. We want to offer companies a working solution. Visitors to Polyclose are therefore welcome to speak with us about the possibilities without obligation. We can show at the fair what we mean by optimizing the production process."

Tryma

Tryma has a booth at Polyclose that includes a robot for mounting hardware, a roll-in machine for seals and a buffer sorting system for glass, windows and doors. The company is also showing smart solutions for cutting glass slats. The team is happy to show visitors even more possibilities in the field of robotization and automation.

Want to know more now? Then check out www.tryma.eu/polyclose